Kerosene stove with primary gasifying tube

A primary gasification and kerosene technology, applied in the field of kerosene stoves, can solve the problems of large heat loss, large noise, and large space occupation, and achieve the effect of full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

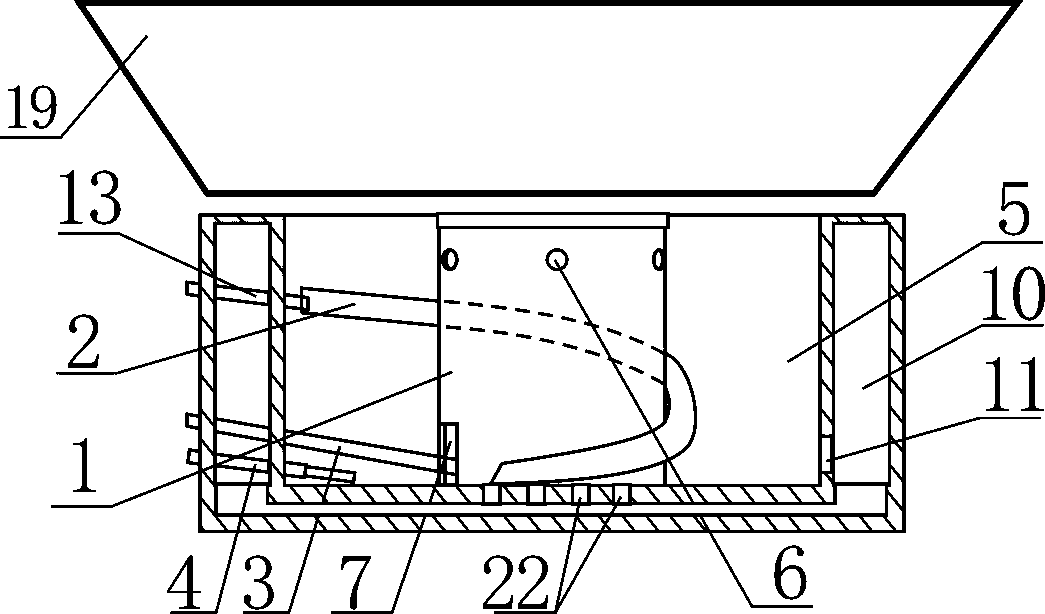

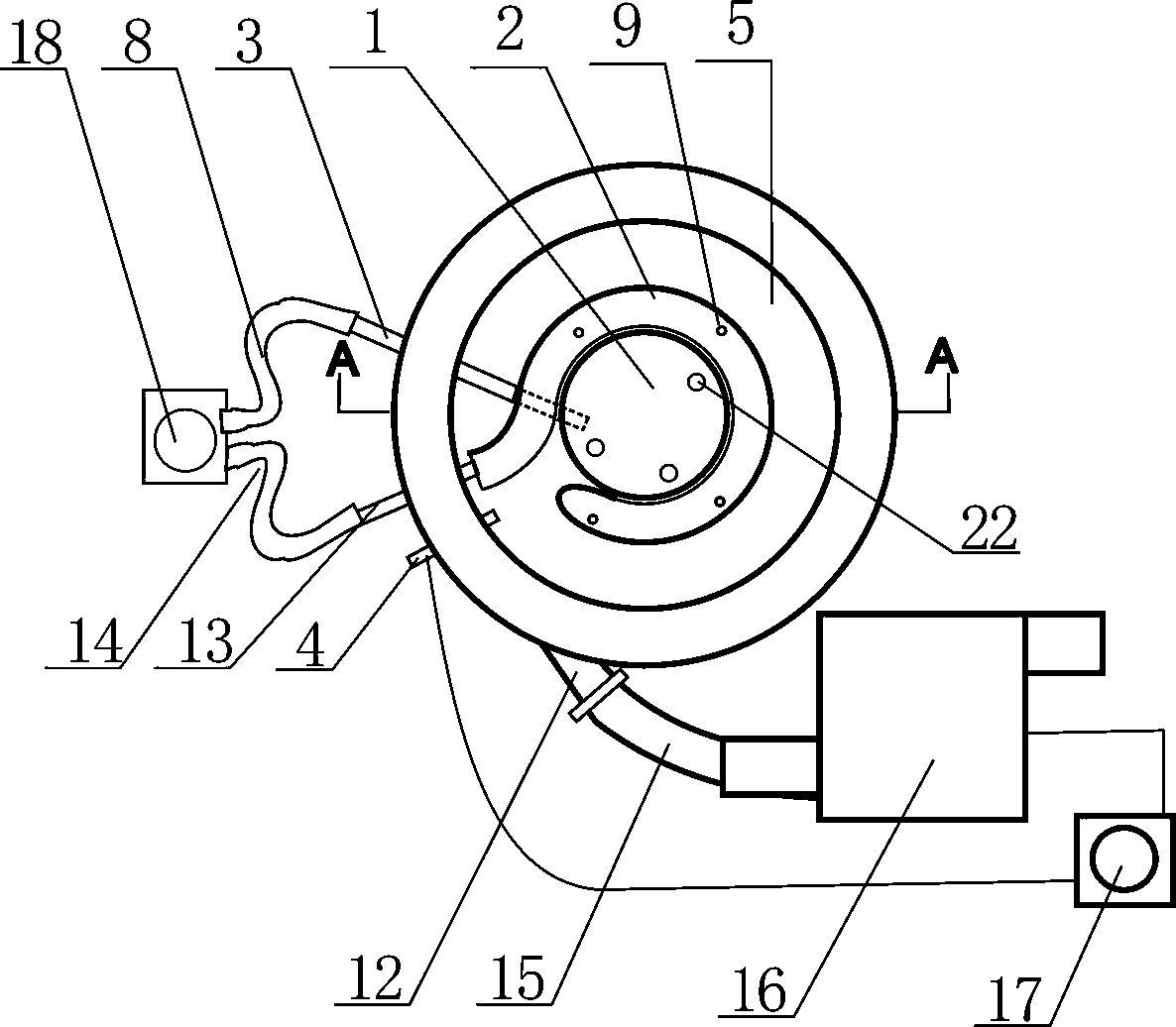

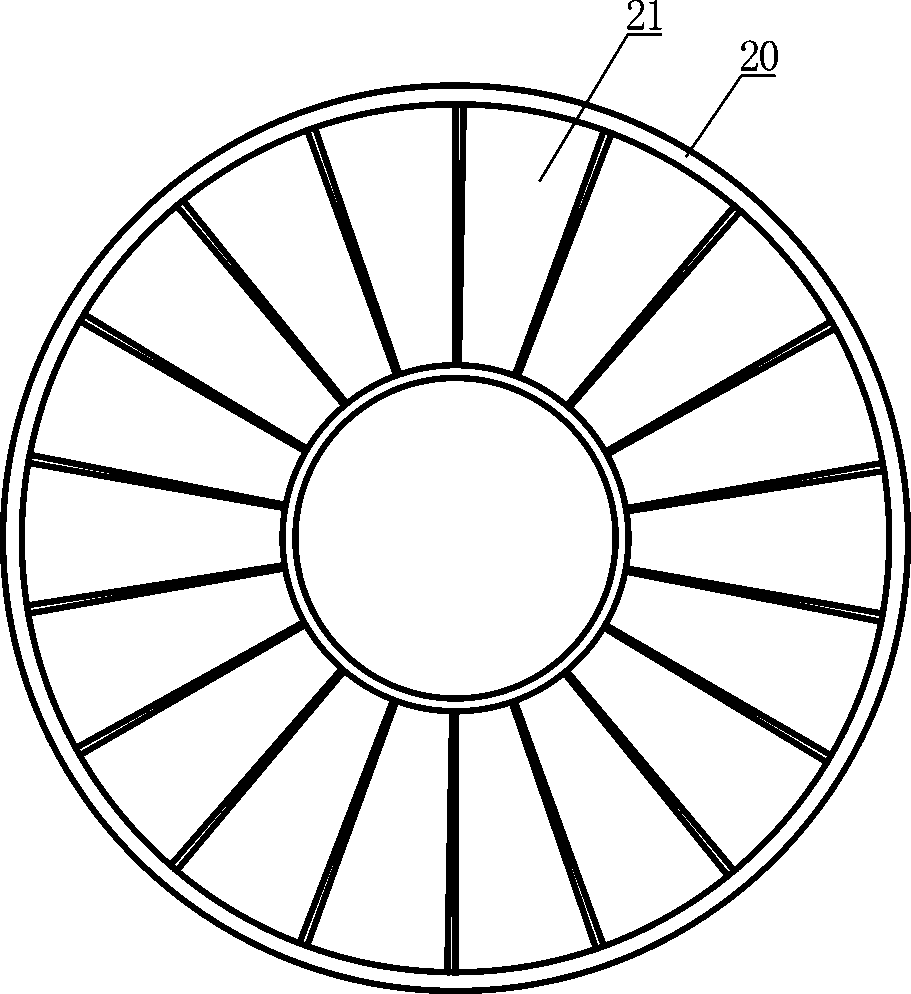

[0012] Such as figure 1 , 2 , 3, the kerosene stove with the primary gasification tube includes an igniter 4, a fan 16 and a power supply 17, wherein the power supply 17 supplies power for the igniter 4 and the fan 16, and one end of the igniter 4 is located in the combustion chamber Inside B5. It also includes combustion chamber A1, spiral pipe A2, spiral pipe B3, and a combustion chamber B5 with an open top and a closed bottom. The combustion chamber A1 is located in the combustion chamber B5. Fixed on the bottom surface of the combustion chamber B5, the upper part of the barrel wall of the combustion chamber A1 is distributed with gas through holes 6 at intervals along the circumferential direction, and the bottom side of the barrel wall of the combustion chamber A1 is provided with an introduction hole 7, and one end of the spiral tube B3 It extends into the combustion chamber A1 through the introduction hole, and the other end passes through the side wall of the combust...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap