Titanium nickel niobium alloy barrier for low-emissivity coatings

A low-radiation, barrier layer technology, applied in coatings, metal material coating processes, layered products, etc., can solve the problems of reduced visible light transmittance of reflective layers, increased overall manufacturing costs, and decreased manufacturing throughput.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The details of one or more embodiments are described below with reference to the accompanying drawings. Detailed descriptions are provided for these embodiments, but are not limited to any particular example. The scope is limited only by the claims and encompasses various alternatives, modifications and equivalents. In the following description, numerous specific details are set forth in order to provide a thorough understanding. These details are provided for purposes of example, and the described techniques may be practiced according to the claims without some or all of the specific details. For the purpose of clarity, technical material that is known in the technical fields related to the embodiments has not been described in detail to avoid obscuring the description.

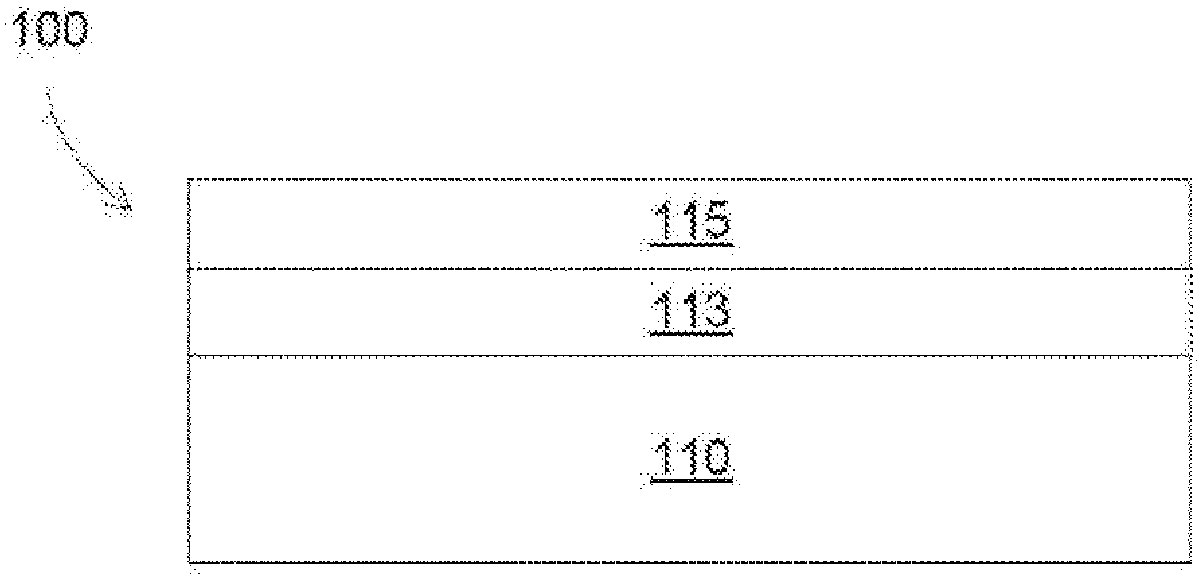

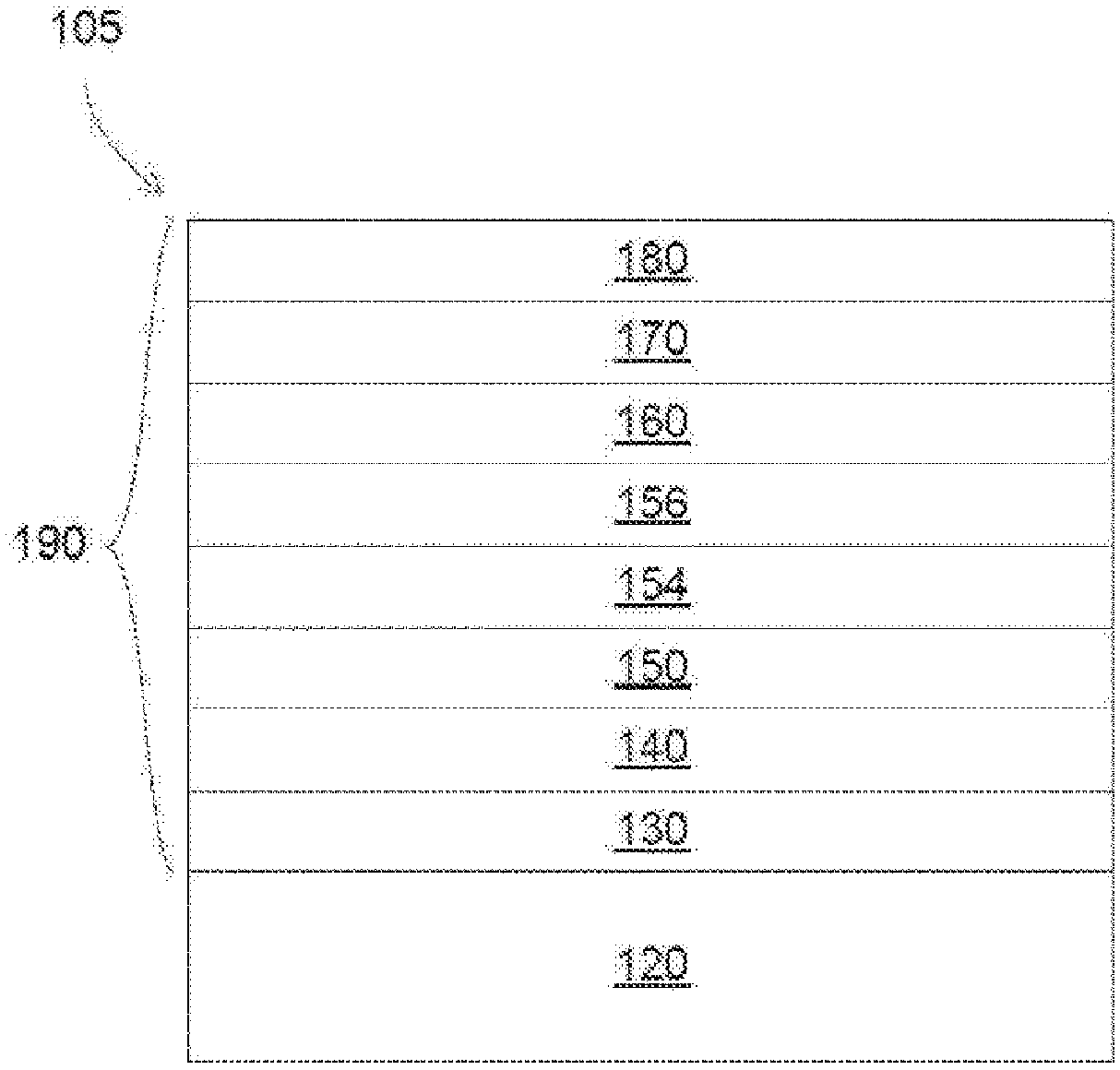

[0023] In some embodiments, a method and apparatus for making a coated panel is disclosed. The coated panel may include a coating formed thereon, for example a thin infrared reflective layer of low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap