Motorcycle frame and motorcycle

A technology for motorcycles and frames, applied in the field of motorcycle frames and motorcycles, can solve the problems of increasing the weight of the whole vehicle, the weight of the frame, and the thickness of the frame, so as to reduce the weight, space occupation, and width. The effect of size and weight reduction of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

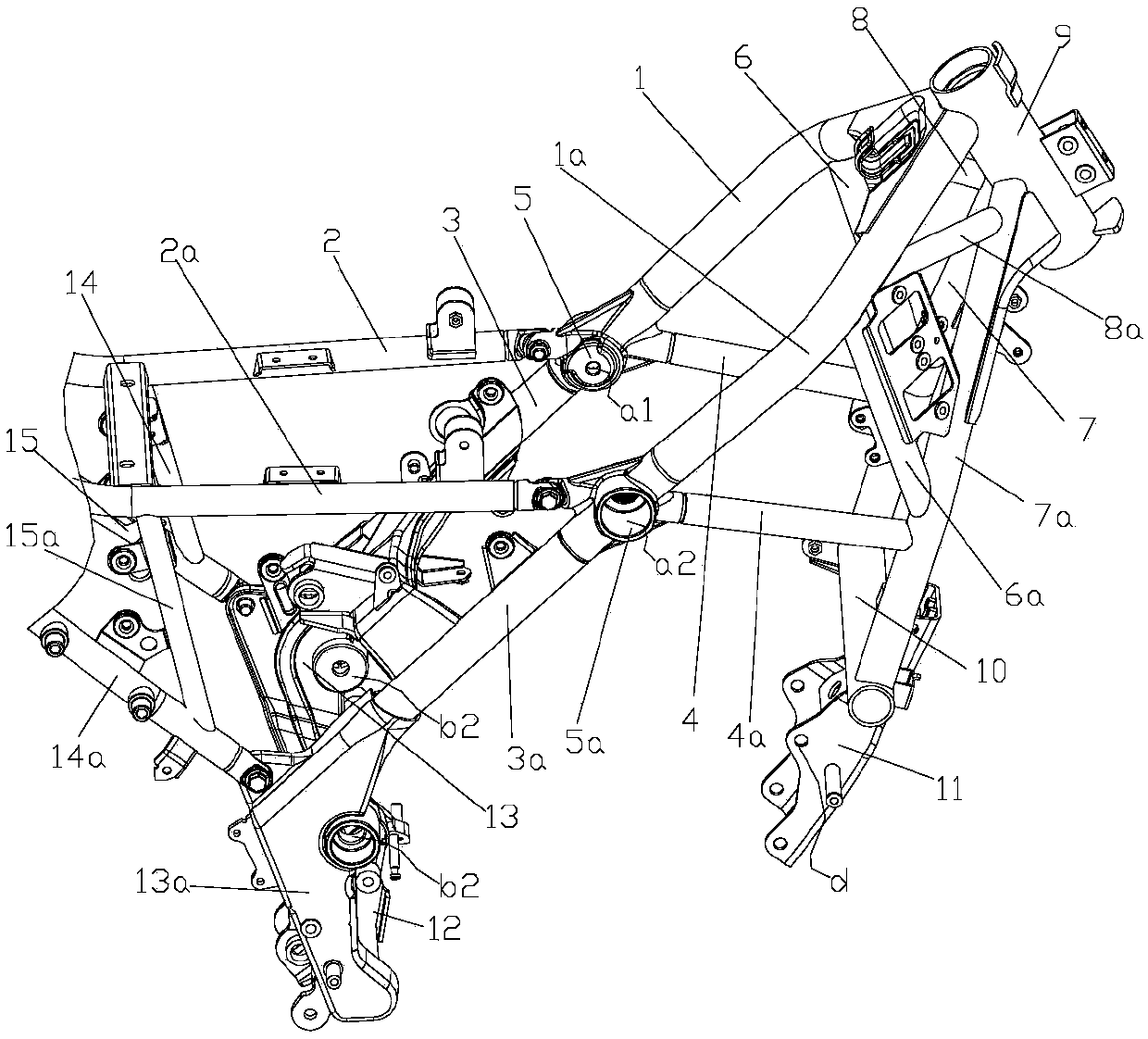

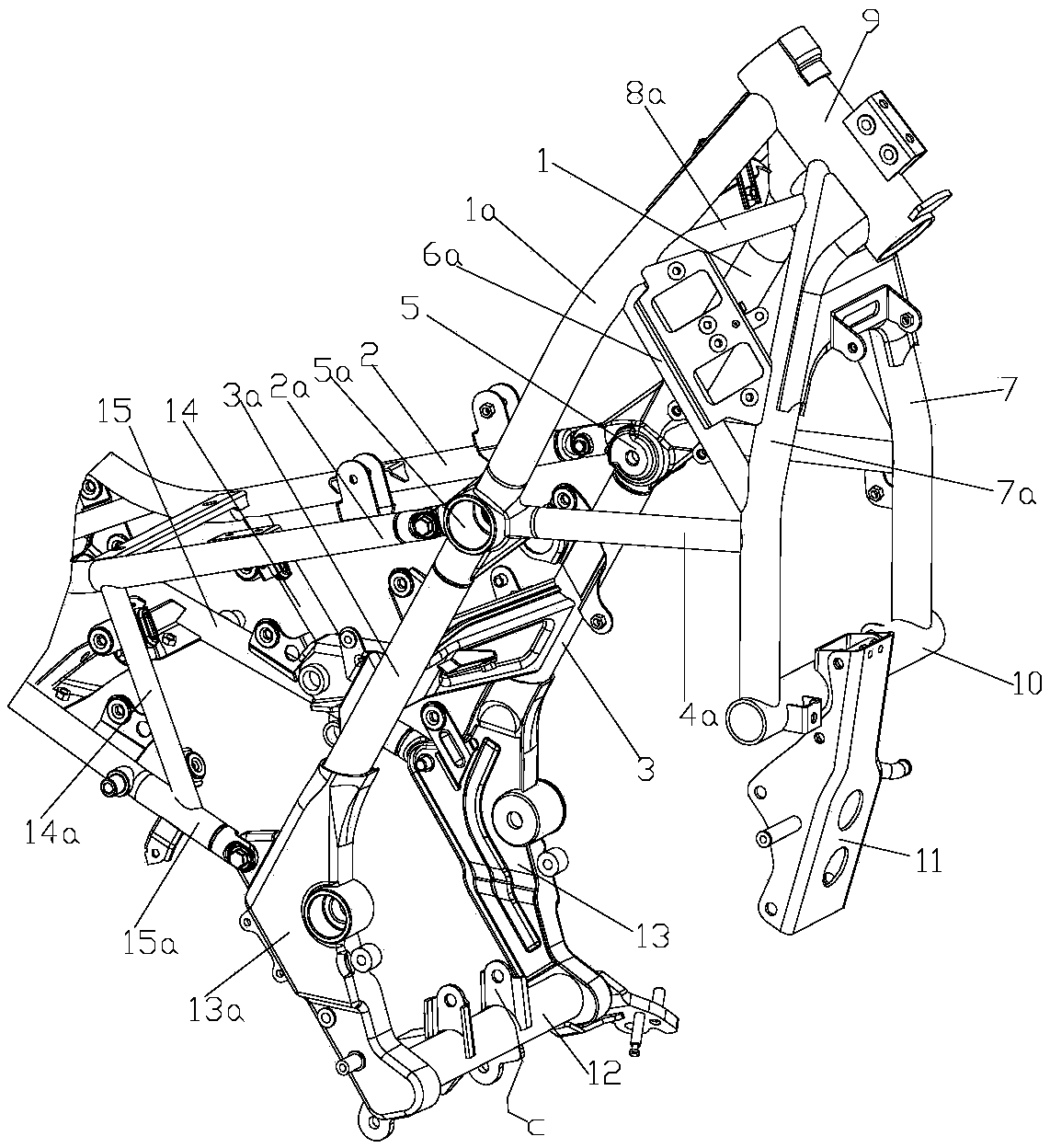

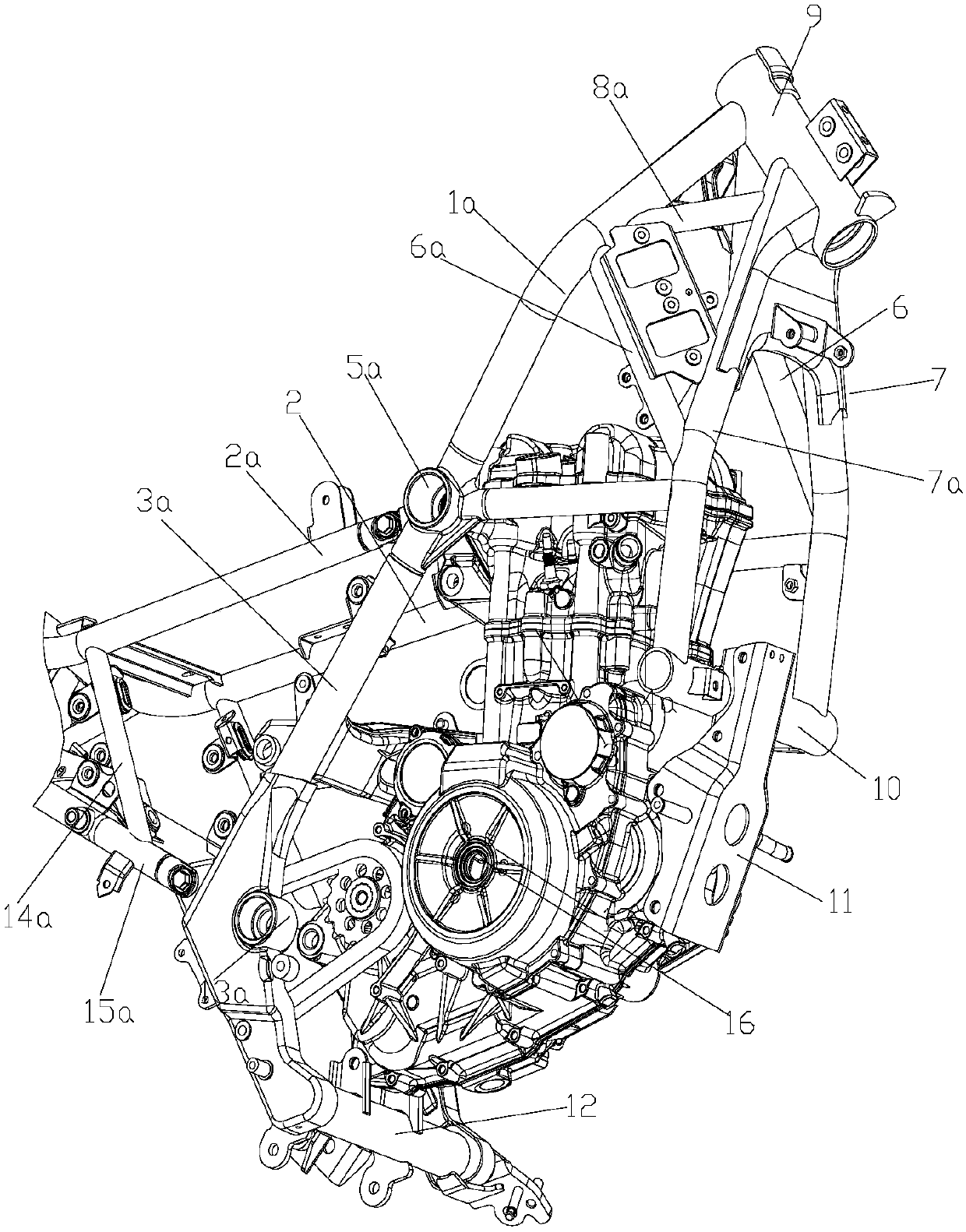

[0022] figure 1 It is the upper axonometric drawing of the present invention, figure 2 It is the axonometric drawing of the bottom of the present invention, image 3 For installing the schematic diagram of engine (use state), as shown in the figure: the motorcycle frame of the present embodiment comprises head tube 9, upright beam, front upper main beam and front lower main beam, and described upright beam comprises upper end average The left upright beam 7 and the right upright beam 7a fixed on the head pipe, the front upper main beam includes the left front upper main beam 1 and the right front upper main beam 1a whose front ends are all fixed on the head pipe and whose rear ends are obliquely extending backward and downward. The beam includes a front end corresponding to the left front lower main beam 4 and the right front lower main beam 4a respectively fixed on the left vertical beam and the right vertical beam; the rear end of the left front lower main beam 4 and the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap