Reusable plastic bobbin

A yarn bobbin and plastic technology, applied in the field of plastic yarn bobbins, can solve the problems of easy deformation and mildew of the paper tube, difficult disassembly and assembly by users, high production cost, and achieve the effects of improving market competitiveness, avoiding repeated processing and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

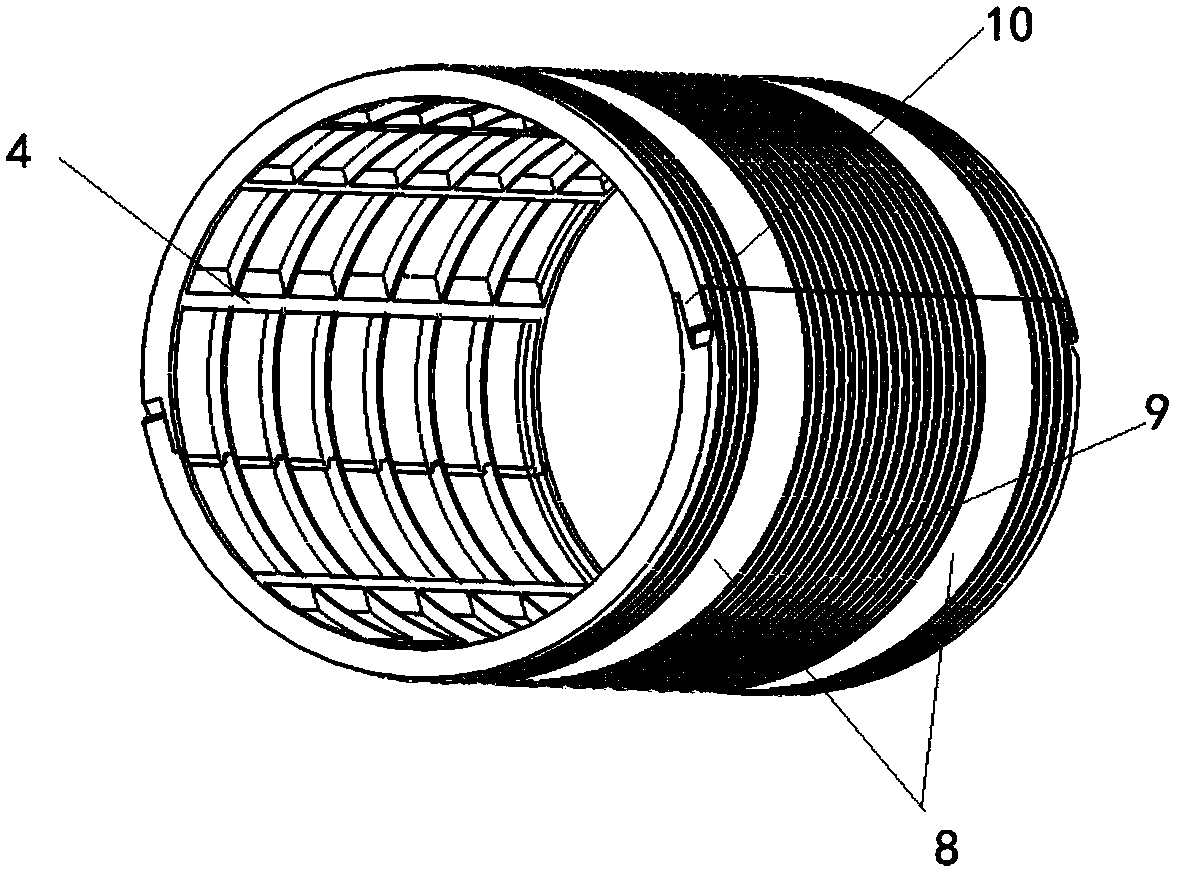

[0029] The reusable plastic bobbin of the present invention has a cylindrical structure.

[0030] The reusable plastic yarn bobbin of the present invention includes a cylindrical pipe body, which is formed by fastening two semi-cylindrical pipe bodies with the same structure. The pipe body is injection molded by ABS engineering plastics with an injection molding machine.

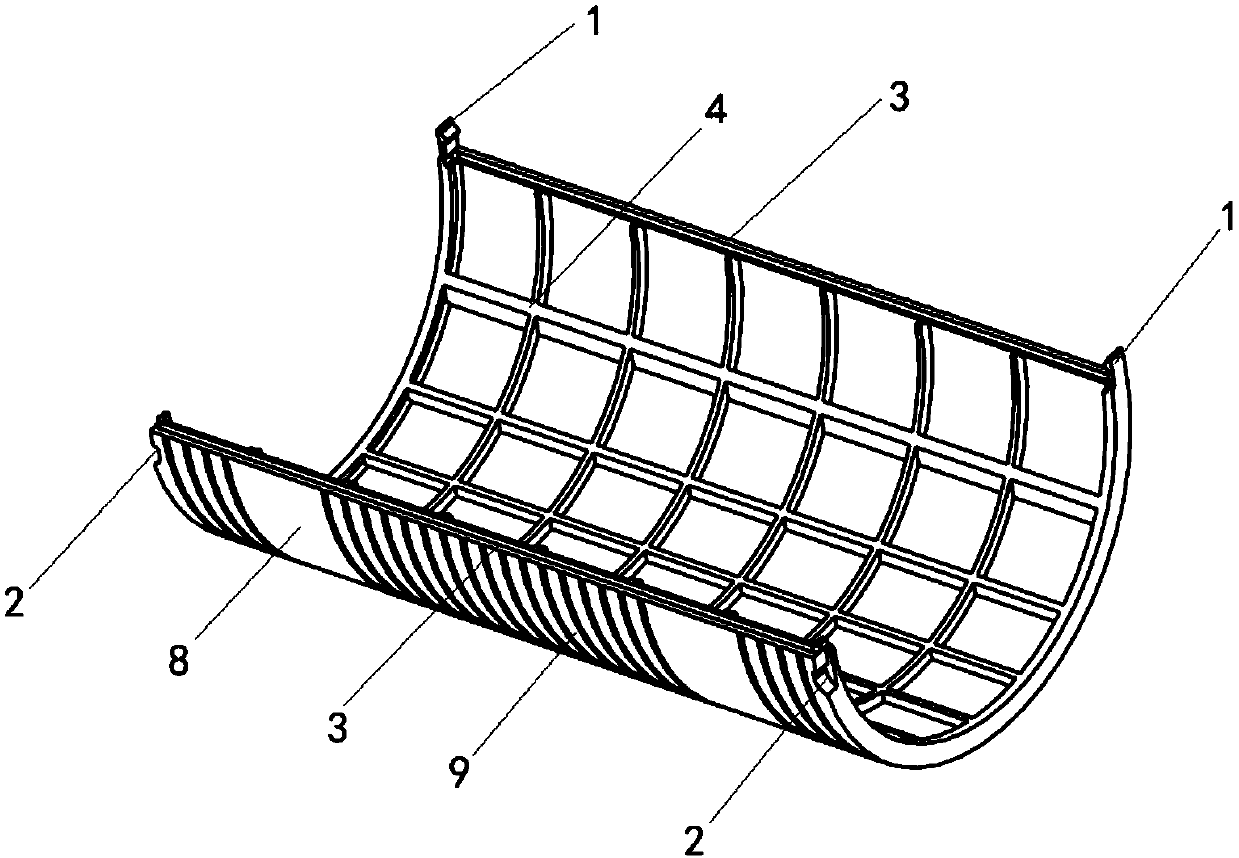

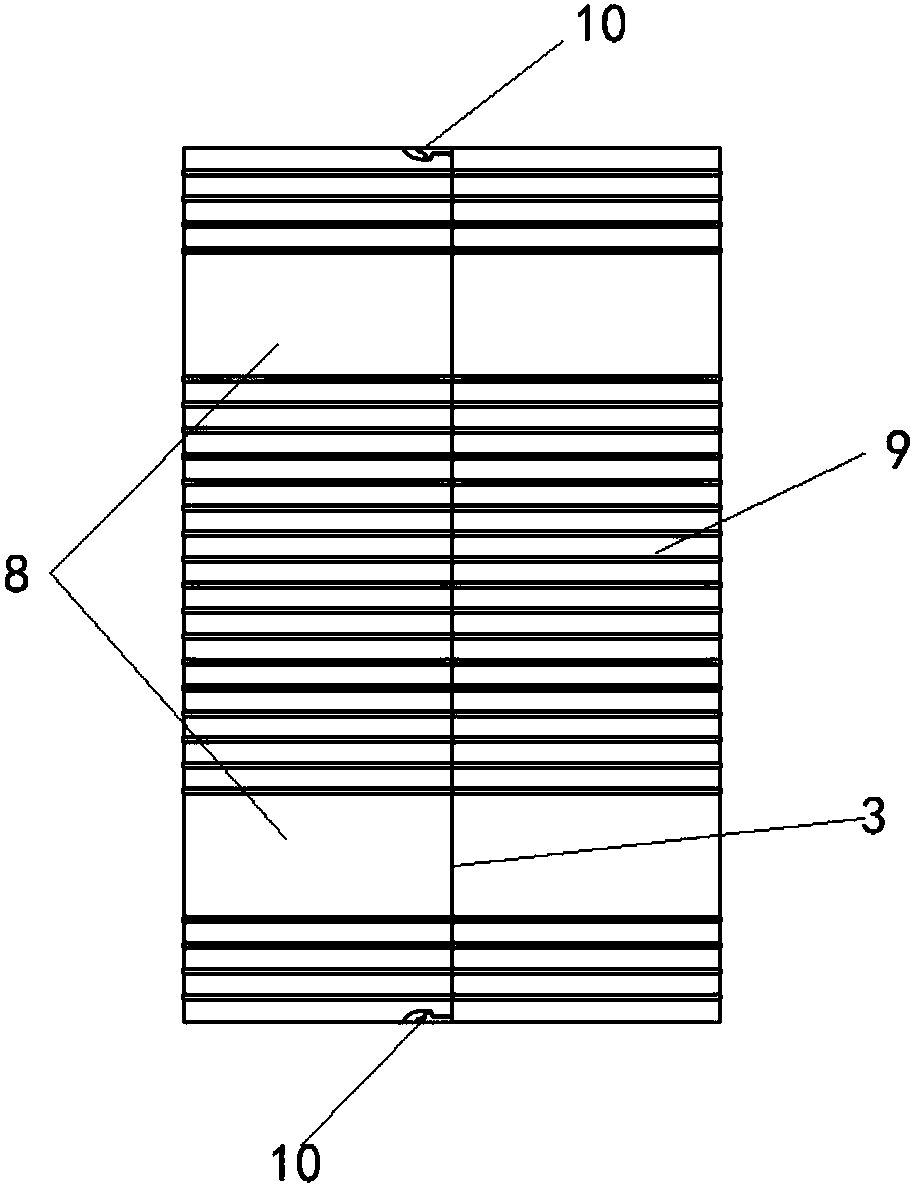

[0031] In an embodiment of the reusable plastic bobbin of the present invention, such as figure 1 with figure 2 As shown, the semi-cylindrical body is provided with anti-skid lines 9 , fastening winding grooves 8 , anti-displacement card slots 3 and quick card slot combinations 10 .

[0032] combine image 3 with Figure 4 , the anti-slip lines 9 are evenly distributed on the outer surface of the semi-cylindrical body, and a fastening winding groove 8 is reserved in the area of the anti-slip lines. Two fastening winding grooves 8 are provided.

[0033] The anti-displacement slots 3 are a pair of mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com