Sewage advanced treatment process

An advanced treatment and process technology, applied in the field of water pollution control, can solve the problems of large aeration volume, easy impact on biofilm, uneven oxygen distribution, etc., and achieve the effect of high removal rate and strong coagulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

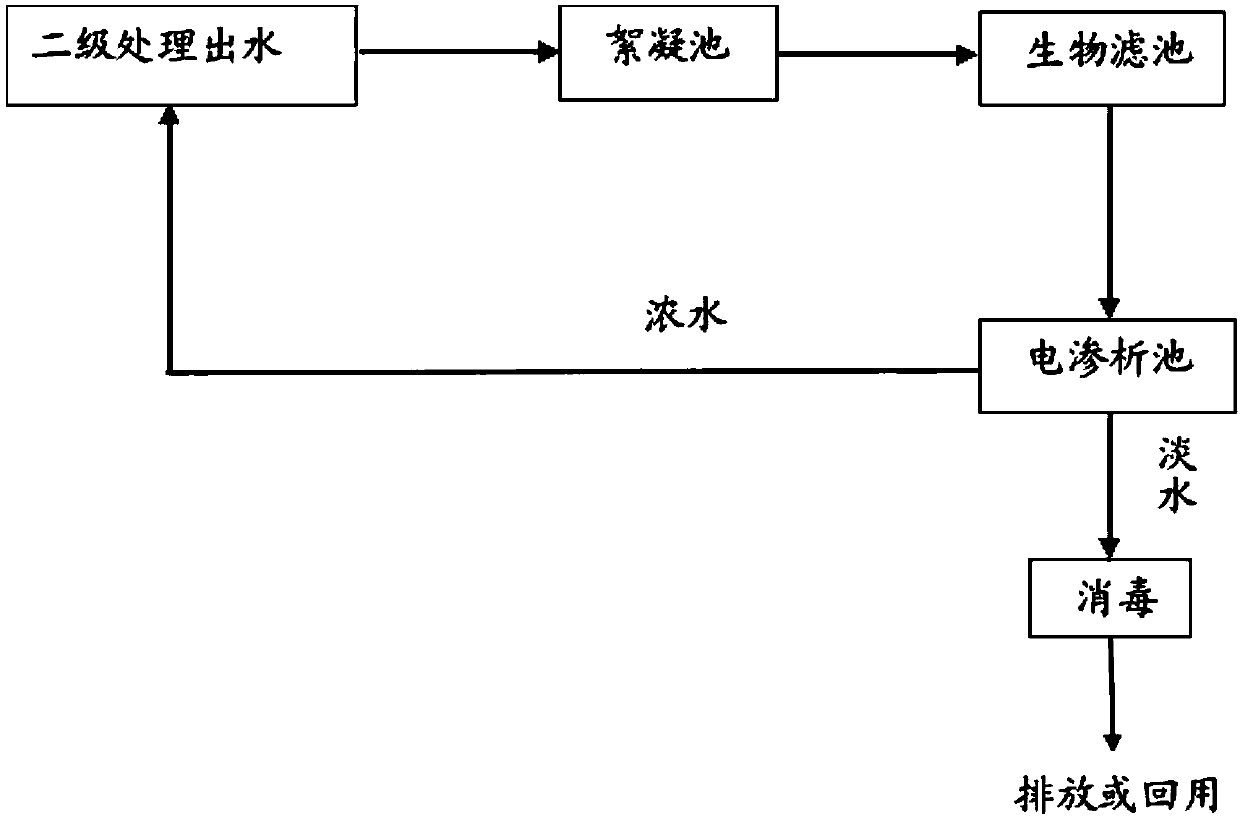

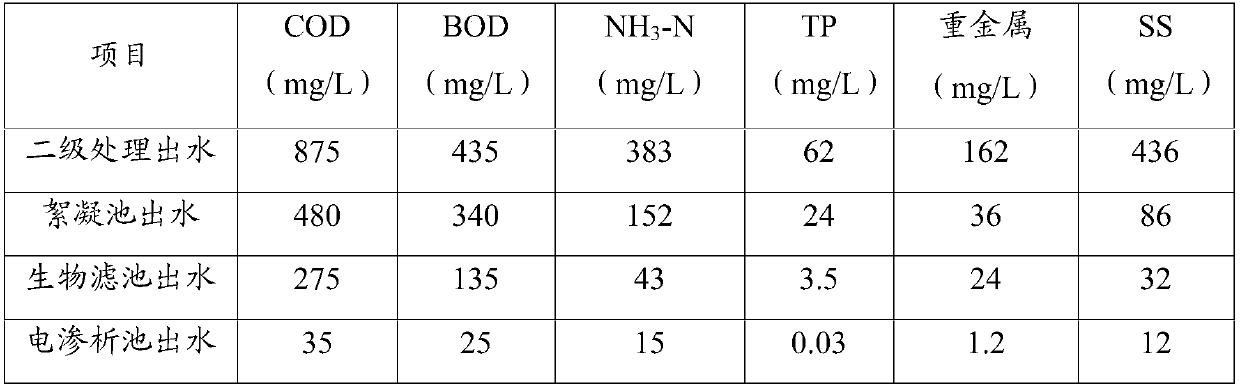

[0033] A sewage advanced treatment process, comprising the following steps:

[0034] Step 1. After the secondary treatment, the effluent enters the coagulation tank, and the composite adsorbent is added to the coagulation tank. After the addition is completed, it is stirred at a speed of 200r / min for 15 minutes. ;

[0035] Wherein, the composite adsorbent is composed of the following components in parts by mass: 5 parts of polyaluminum ferric chloride, 40 parts of oligosaccharide-modified medical stone, and 10 parts of modified semi-coke;

[0036] The dosage of the composite adsorbent is 3kg per ton of waste water;

[0037] Step 2, the effluent from the coagulation tank enters the biofilter, and the biofilter is filled with biological fillers, the biological fillers are mixed with modified porous ceramic particles and compound algae bacterial agents according to the mass ratio of 15:1. The biofilter adopts micro-aeration to provide oxygen, and the gas-water ratio in the biof...

Embodiment 2

[0046] A sewage advanced treatment process, comprising the following steps:

[0047] Step 1. After the secondary treatment, the effluent enters the coagulation tank, and the composite adsorbent is added to the coagulation tank. After the addition is completed, it is stirred at a speed of 250r / min for 12 minutes. ;

[0048] Wherein, the composite adsorbent is composed of the following components in parts by mass: 8 parts of polyaluminum ferric chloride, 35 parts of oligosaccharide-modified medical stone, and 15 parts of modified semi-coke;

[0049] The dosage of the composite adsorbent is 2kg per ton of waste water;

[0050] Step 2, the effluent from the coagulation tank enters the biofilter, and the biofilter is filled with biological fillers, the biological fillers are mixed with modified porous ceramic particles and compound algae bacterial agents according to the mass ratio of 12:1, the resulting The biofilter adopts micro-aeration to provide oxygen, and the air-water rat...

Embodiment 3

[0056] A sewage advanced treatment process, comprising the following steps:

[0057] Step 1. After the secondary treatment, the effluent enters the coagulation tank, and the composite adsorbent is added to the coagulation tank. After the addition is completed, it is stirred at a speed of 300r / min for 10 minutes. ;

[0058] Wherein, the composite adsorbent is composed of the following components in parts by mass: 10 parts of polyaluminum ferric chloride, 30 parts of oligosaccharide-modified medical stone, and 20 parts of modified semi-coke;

[0059] The dosage of the composite adsorbent is 1kg per ton of waste water;

[0060] Step 2, the effluent from the coagulation tank enters the biofilter, and the biofilter is filled with biological fillers, which are mixed with modified porous ceramic particles and compound algae bacterial agents in a mass ratio of 10:1. The biofilter adopts micro-aeration to provide oxygen, and the air-water ratio in the biofilter is set to be 3:1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap