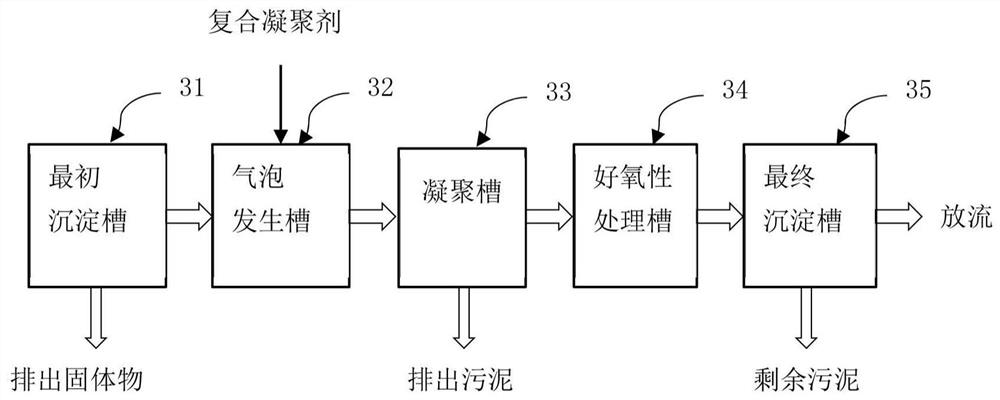

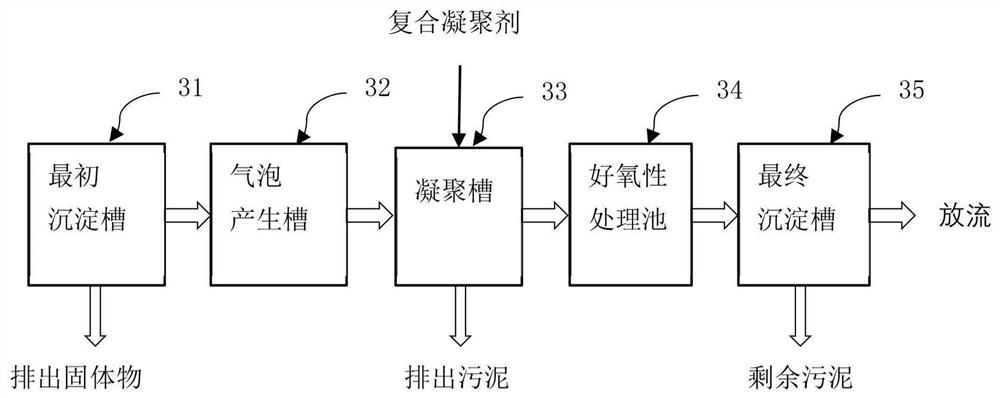

Composite coagulant and wastewater treatment system using same

A technology of composite coagulation and coagulation agent, applied in the direction of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, separation methods, etc., to achieve the effect of large sedimentation velocity and strong coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

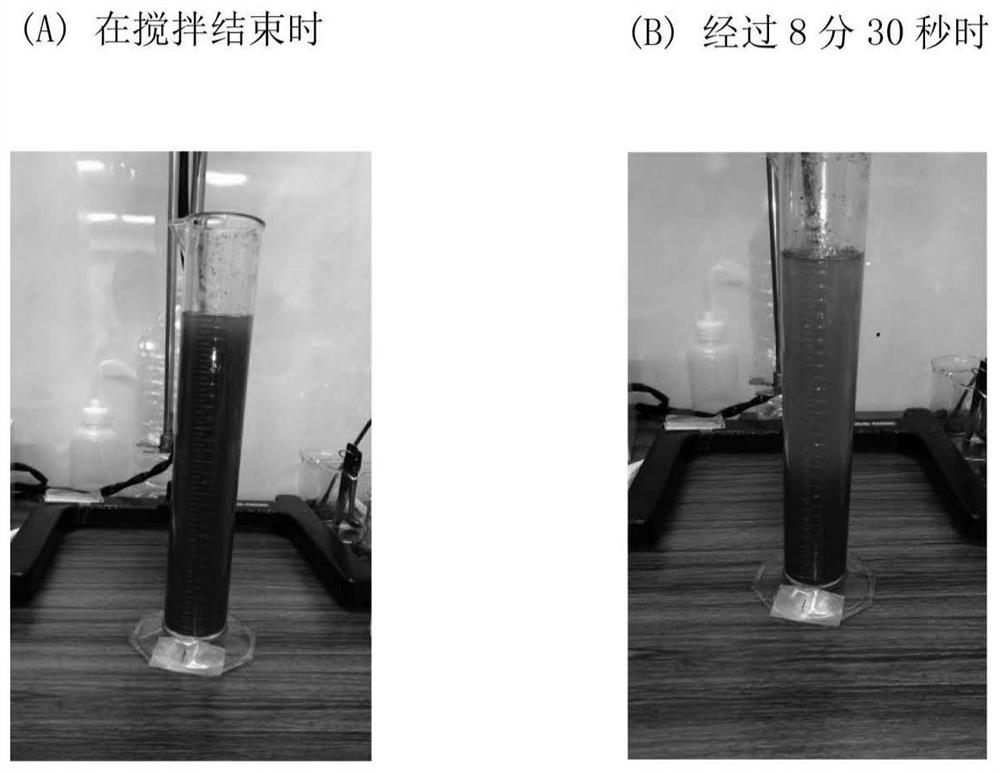

[0030] A first example of the complex coagulant of the present invention will be described.

[0031]

[0032] Room temperature: 24°C

[0033]

[0034] As the carbide coagulants A, B, C, and D, charcoal produced in a carbonization furnace manufactured by Meiwa Kogyo Co., Ltd. (Kanazawa, Ishikawa Prefecture) was prepared.

[0035] Carbide flocculant A: carbonization of rice husks at 800°C by external heat, based on the classification of stainless steel sieves to obtain finer particles with a diameter of 250 μm or less

[0036] Carbide coagulant B: carbonization of rice husks at 400°C by external heat, based on the classification of stainless steel sieves to obtain finer particles with a diameter of 250 μm or less

[0037] Carbide flocculant C: The fir chips are subjected to external thermal carbonization at 800°C, and are classified into fine particles with a diameter of 250 μm or less based on stainless steel sieves

[0038] Carbide flocculant D: The fir wood chips are ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap