A method of crystal growth

A growth method and crystal technology, applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of lower seeding quality, long time required, slow growth rate, etc., to shorten seeding time and improve Effect of Seed Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

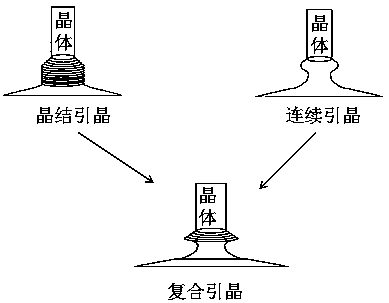

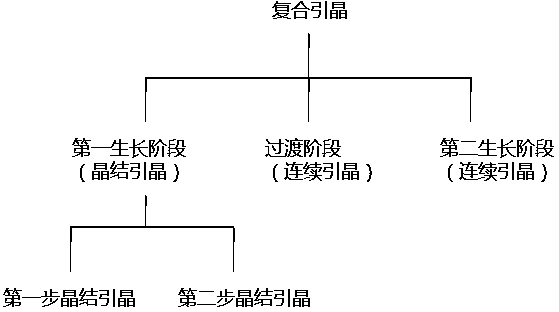

[0024] see figure 1 , the present invention provides a kind of crystal growth method, grow crystal in the crystal growth furnace, improve and integrate the original seeding process, the original inherent single seeding method (crystallization seeding or continuous seeding) integrated into the same novel seeding process, specifically, see figure 2 , including a first growth stage and a second growth stage in sequence, the first growth stage adopts a crystallization seeding process, and the second growth stage adopts a continuous seeding process.

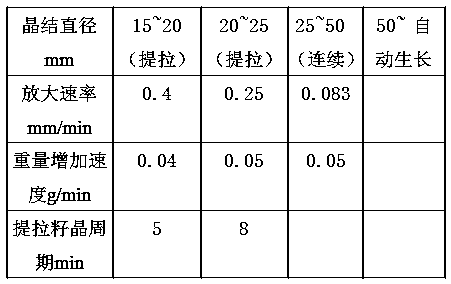

[0025] see image 3 In the chart in the figure, the crystal diameter of the first growth stage ranges from 15 to 25mm, the first growth stage is at least composed of the first step of crystal seeding and the second step of crystal seeding, and the crystal diameter of the first step of crystal seeding The range is 15~20mm, the crystal amplification rate of the first step of crystallization seeding is 0.3~0.5mm / min, preferably 0.4mm / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com