A sub-module pressure equalization control method in the process of switching on and off of a converter station and its valve group

A technology of voltage equalization control and valve group, which is applied in the direction of converting AC power input to DC power output, output power conversion devices, electrical components, etc., and can solve overvoltage/undervoltage of half-bridge sub-modules and clamping twin sub-modules, etc. Problems such as uneven voltage and cost increase achieve the effect of solving current impact, reducing equipment cost, and strengthening technical economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

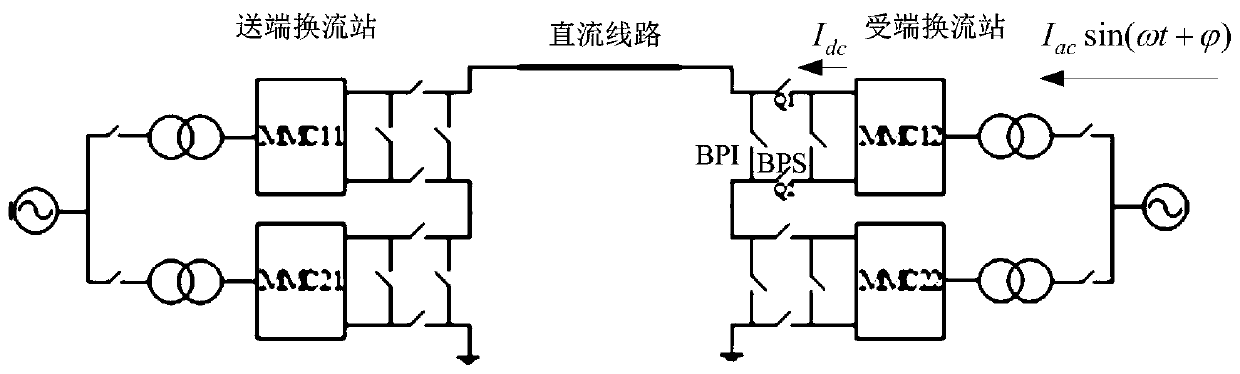

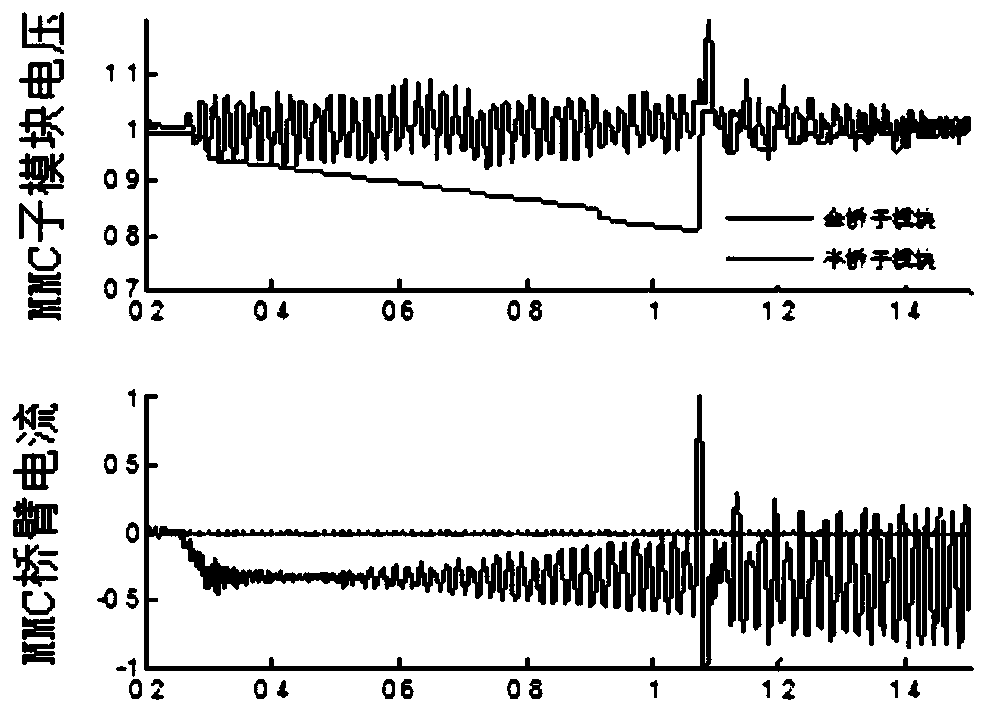

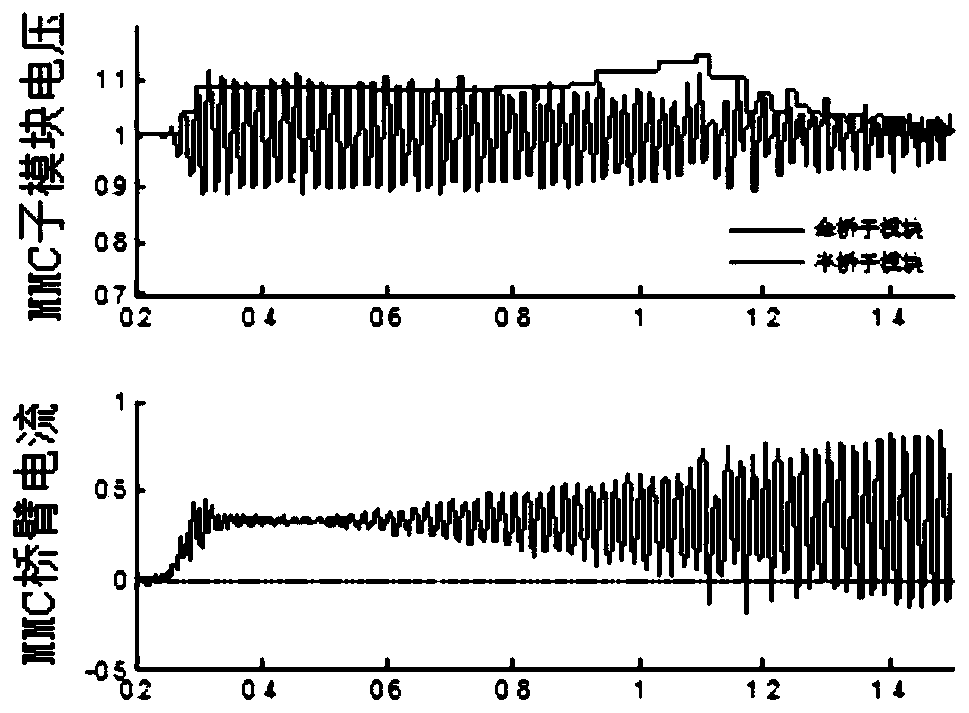

[0038] For such as figure 1 The single-stage system of the double-ended high-voltage flexible DC system shown is analyzed as diagram 2-1 , Figure 2-2 It can be seen from the simulated waveform diagrams of sending and receiving ends during the operation of the valve group when the proportion of the MMC full-bridge sub-module under conventional control is 50% and the content in the background technology. , the upper and lower arm currents of phase A of the MMC high valve group at the sending end are And it is always negative; the upper and lower bridge arm currents of phase A of the MMC high valve group at the receiving end are And it is always positive, that is to say, the root cause is that there is no positive and negative alternation in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com