Valve device for a fuel injection system and fuel injection system

A technology of fuel injection system and valve device, which is applied in the direction of fuel injection device, special fuel injection device, charging system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

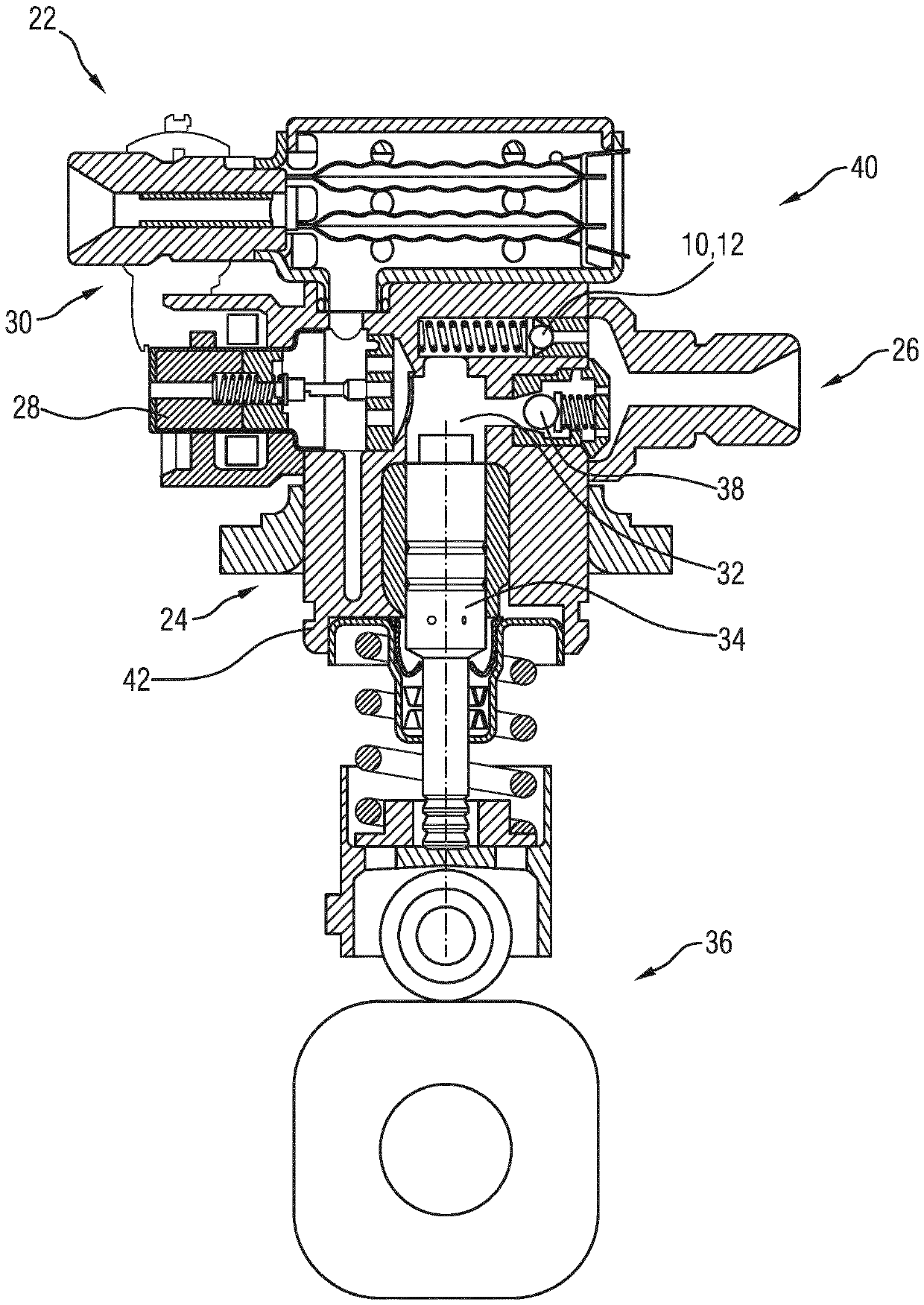

[0038] figure 1 A longitudinal section through a fuel injection system 22 is shown, via which fuel can be injected into at least one combustion chamber of the internal combustion engine. Fuel injection system 22 has a high pressure fuel pump 24 and a fuel storage area 26 .

[0039] Fuel is loaded at high pressure by a high-pressure fuel pump 24 , for example diesel at a pressure between 1500 and 3000 bar or gasoline at a pressure between 200 and 350 bar. For this purpose, fuel enters the pressure space 32 of the high-pressure fuel pump 24 from the low-pressure region 30 via the inlet valve 28 . The pump piston 34 , which is driven by the drive device 36 , moves in translation to and fro in the pressure space 32 and in the process reduces or increases the volume of the pressure space 32 . In this way, the fuel in the pressure space 32 is compressed and thus pressurized. After compression in the pressure space 32 , the fuel exits the pressure space 32 via an outlet valve 38 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com