Production method of minced oyster meat gel product

A production method and technology of oyster meat, which is applied in the production field of oyster meat mince gel products, can solve the problems of easy corruption, high transportation costs, hazards, etc., and achieve the effect of being convenient to eat, rich in nutrition, and overcoming complicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

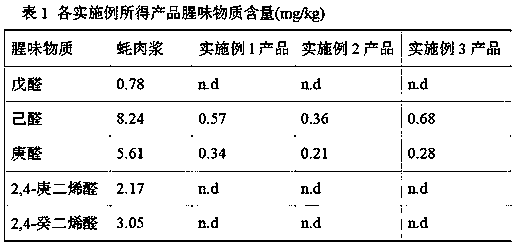

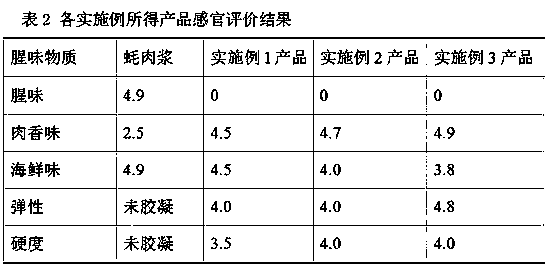

Examples

Embodiment 1

[0037] The production method of the oyster mince gel product of the present embodiment comprises the following steps:

[0038] (1) Wash 5.0kg shelled oysters and remove the viscera to obtain oyster meat;

[0039] (2) Beat the raw oyster meat obtained in step (1) to obtain 1.0 kg of oyster meat pulp;

[0040] (3) Add 2.0 kg of frozen surimi to the oyster meat slurry obtained in step (2), chop and mix for 5 minutes to obtain 3.0 kg of mixed minced meat;

[0041] (4) Add 60g of salt to the mixed minced meat obtained in step (3), and continue to chop and mix for 5 minutes; add 150g of starch, 100g of soybean protein isolate, 30g of yeast cell enzyme extract, 10g of sodium hexametaphosphate, and 300g of crushed ice, and continue to chop and mix 5min to obtain the processed mixed minced meat;

[0042] (5) Forming: extruding the mixed minced meat processed in step (4) into blocks;

[0043] (6) Gelation: heat gelation, heat at 40°C for 60 minutes, then heat at 85°C for 30 minutes t...

Embodiment 2

[0047] This embodiment includes the following steps:

[0048] (1) 10.0kg oysters with shells are taken for meat, cleaned, and gutted to obtain oyster meat;

[0049] (2) Beat the raw oyster meat obtained in step (1) to obtain 2.0 kg of oyster meat pulp;

[0050] (3) Add 2.0 kg of lean pork to the oyster meat slurry obtained in step (2), chop and mix for 5 minutes to obtain 4 kg of mixed minced meat;

[0051](4) Add 80 g of salt to the mixed minced meat obtained in step (3), and continue chopping and mixing for 5 minutes; add 200 g of corn starch, 200 g of soybean protein isolate, 30 g of carrageenan, 30 g of tea polyphenols, 50 g of yeast cell enzyme extract, and Sodium phosphate 20g, glucose 200g, active lactic acid bacteria powder 50g, continue chopping and mixing for 5 minutes to get the processed mixed meat;

[0052] (5) Forming: Enema the mixed minced meat processed in step (4);

[0053] (6) Gelling: Use lactic acid bacteria to ferment acid to cause gelling: keep warm a...

Embodiment 3

[0057] This embodiment includes the following steps:

[0058] (1) 5.0kg shelled oysters are taken, cleaned and viscerated to obtain oyster meat;

[0059] (2) Beat the raw oyster meat obtained in step (1) to obtain 1.0 kg of oyster meat pulp;

[0060] (3) Add 2.0kg of lean chicken to the oyster meat slurry obtained in step (2), chop and mix for 5 minutes to obtain 3kg of mixed minced meat;

[0061] (4) Add 60 g of salt to the mixed minced meat obtained in step (3), continue chopping and mixing for 5 minutes; add 150 g of starch, 30 g of yeast cell enzyme extract, 15 g of sodium tetrapolyphosphate, 50 g of gluconolactone, and 50 g of minced garlic, and continue Chop and mix for 5 minutes to get mixed minced meat;

[0062] (5) Forming: Extrude the mixed minced meat processed in step (4) into a ball;

[0063] (6) Gelation: Incubate at 40°C for 1.5 hours to cause gelation, put into packaging bags and seal;

[0064] (7) Sterilization: heat again at 100°C for 30 minutes to steril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com