Stress pattern pressuring and locking osteosynthesis device

A stress and locking hole technology, applied in the direction of fixator, internal fixator, internal bone synthesis, etc., can solve the problems of poor fixation of bone ends and easy fracture of bone plates, so as to prolong the service life, avoid stress shielding, and disperse stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

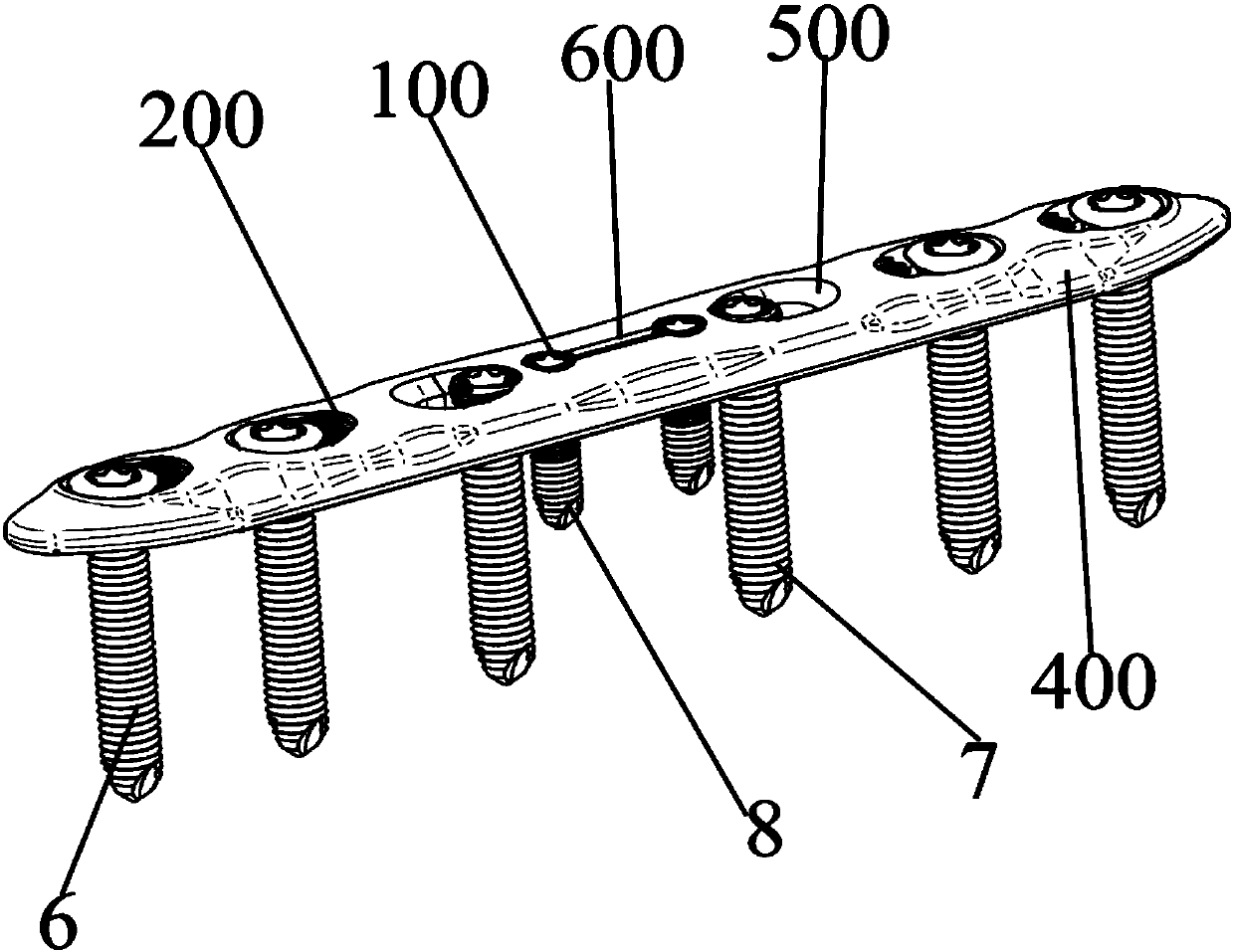

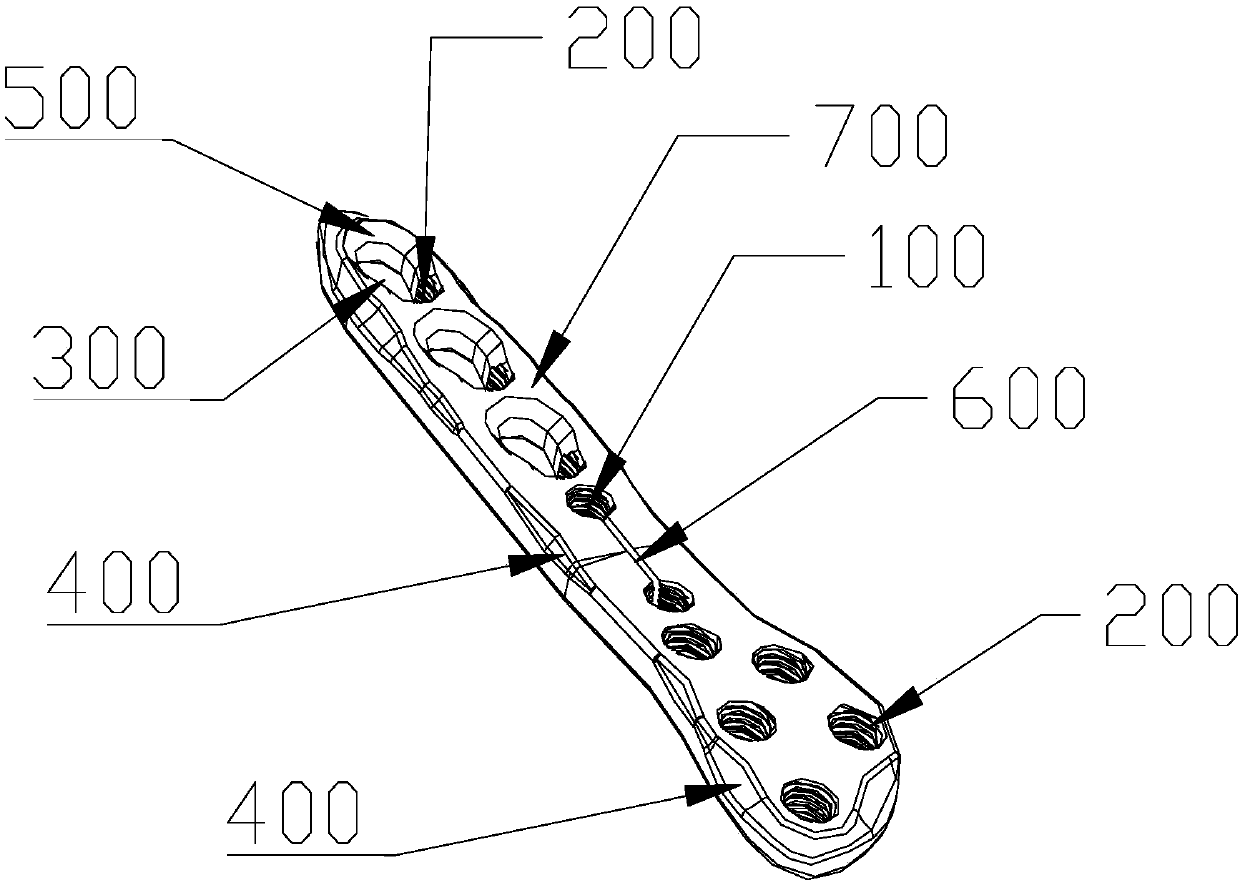

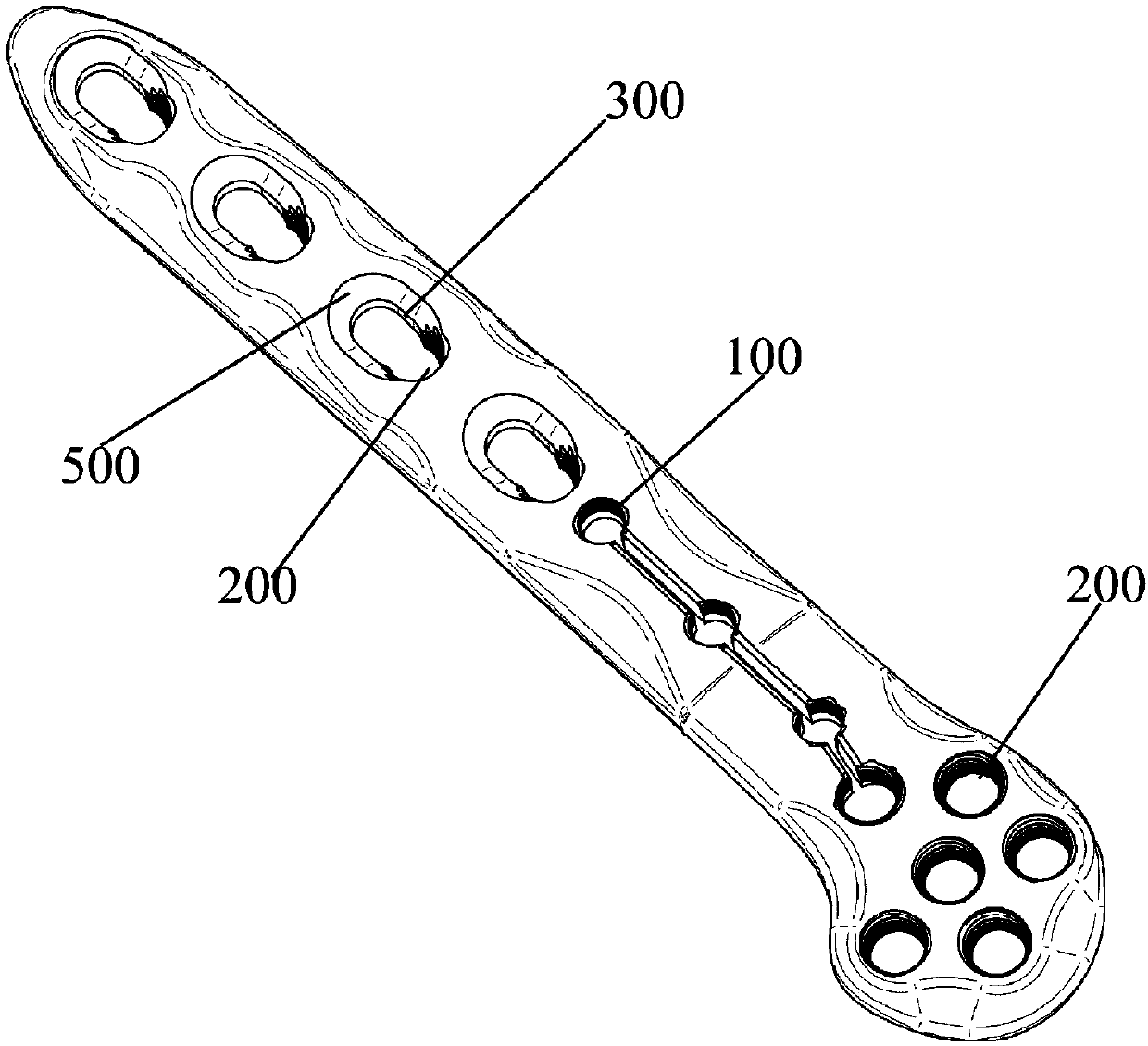

[0035] Such as Figure 1 to Figure 4 As shown, the stress-type compression locking osteosynthesis device of the present invention includes: at least one stress-type bone plate 700, and the stress-type bone plate 700 is provided with a first locking hole 100, a second locking hole 200 and a pressure locking hole 300 , the pressurized locking hole 300 is formed by the second locked hole 200 and the pressurized hole 500 interlaced with each other, and the pressurized lock hole 300 is symmetrically distributed on the stress-type bone plate 700 according to the specific and reasonable distribution; on the upper surface of the stress-type bone plate 700 On the edge side, between adjacent first locking holes 100 , between adjacent pressurization locking holes 300 , between second locking holes 200 and pressurization locking holes 300 , there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com