Water guiding plate for cleaning tank

The technology of a water guide plate and a cleaning tank is applied in the field of water guide plates for cleaning tanks, which can solve the problems of clogging filter holes, troublesome cleaning, bacterial growth, etc., and achieve the effects of improving strength, avoiding sanitary dead corners, and avoiding cleaning dead corners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

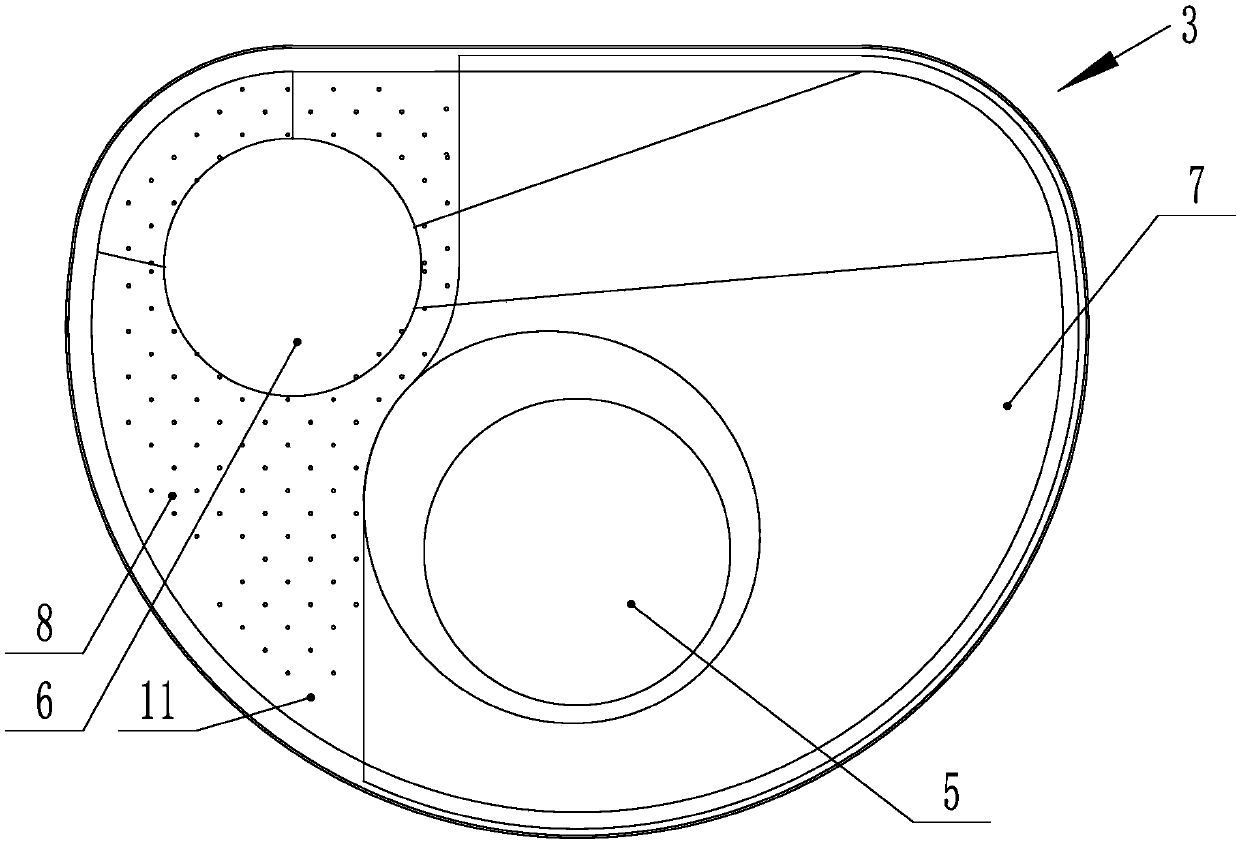

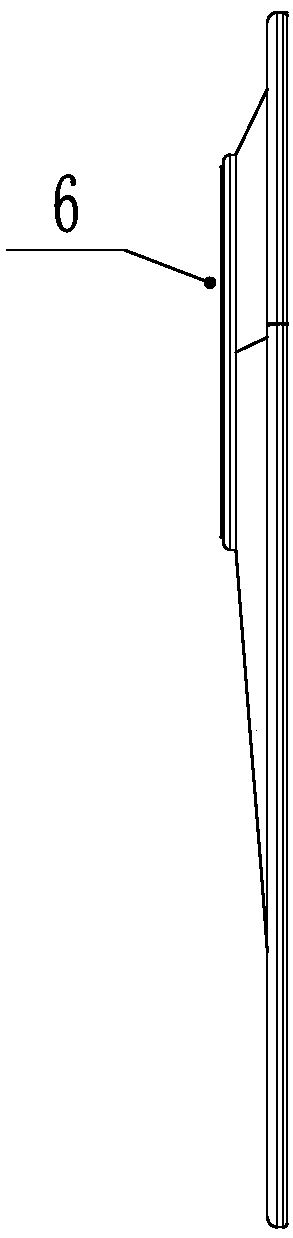

[0034] As shown in Figure 1, a first through hole 5 and a second through hole 6 are provided on the water guide plate 3, the first through hole 5 is located in the middle of the water guide plate 3, and the second through hole 6 It is located at the side of the water guide plate 3; the water guide plate 3 is divided into a light plate area 7 without filter holes 11 and a filter area 8 with filter holes 11. Wherein, the first through hole 5 matches with the cleaning device and is used for passing through the cleaning device. The second through hole 6 is opposite to the sink drain hole and is used for draining water. The local area of the water guide plate 3 is perforated, and the strength of the water guide plate 3 is improved while not affecting the water launch. When a position of the cleaning device is below the bare panel area 7, since no cleaning is required, dead corners of sanitation are avoided, residue residues are reduced, and cleaning ability is improved.

[0035...

Embodiment 2

[0047] The similarities with Embodiment 1 will not be repeated, and the difference is that: figure 2 As shown, the filter hole 11 is a square hole, and its diagonal size is 0.5-1.5 mm.

Embodiment 3

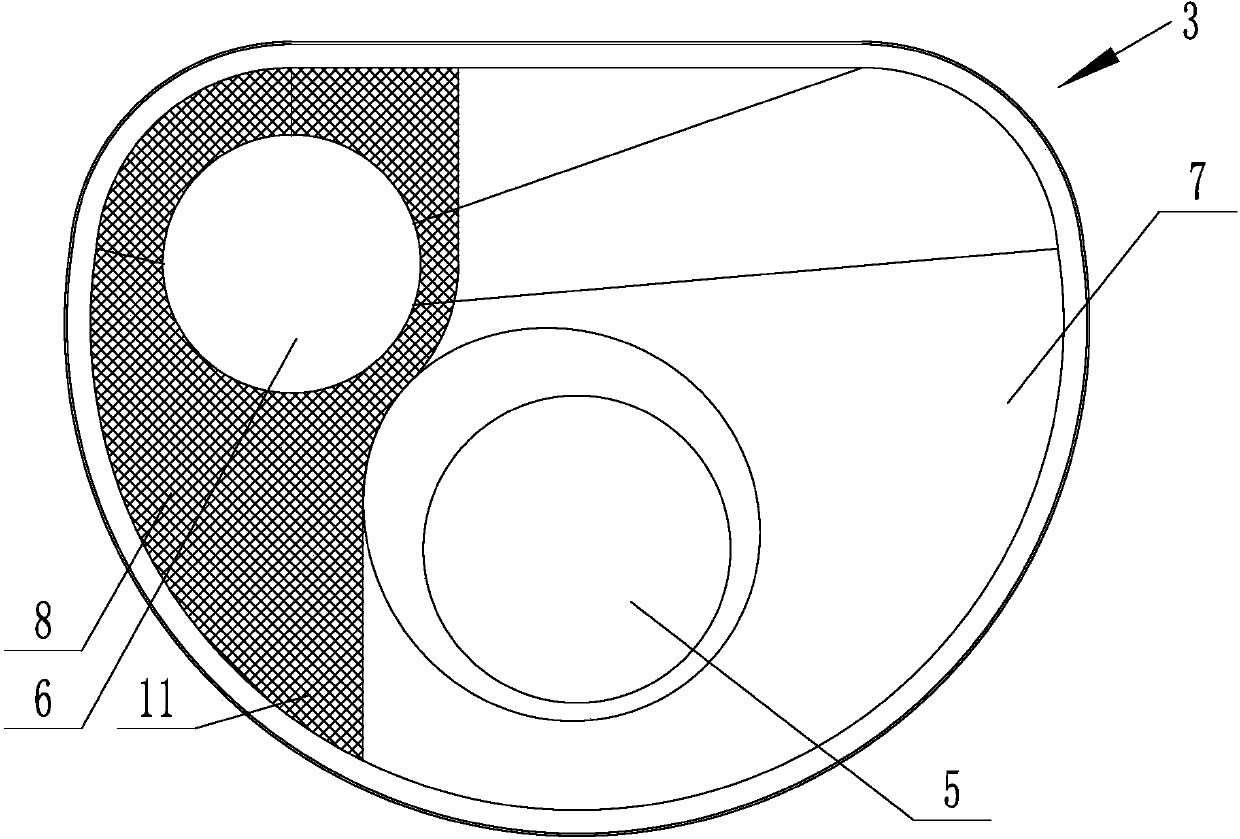

[0049] The similarities with Embodiment 1 will not be repeated, and the difference is that: image 3 As shown, the water guiding plate 3 is provided with a light plate area 7 and two filter areas 8 , and the filter areas 8 are respectively provided with two sides of the light plate area 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com