A golf head clamping jig

A golf head and jig technology, applied in the direction of clamping, manufacturing tools, clamping devices, etc., can solve the problems of inability to meet production and processing needs, harsh processing environment for workers, poor quality of finished products, etc., to reduce labor costs and The effect of error rate, improved range of use, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

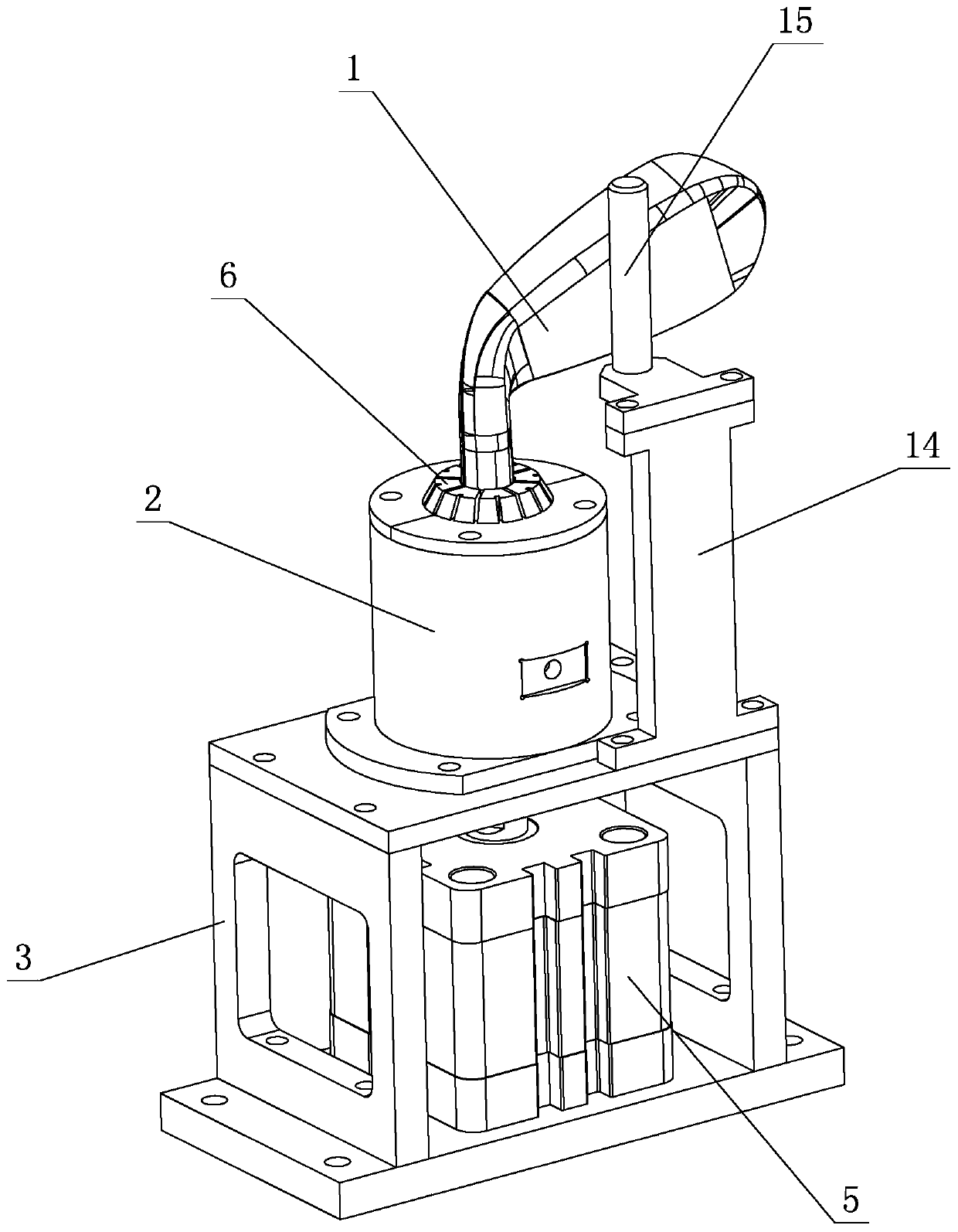

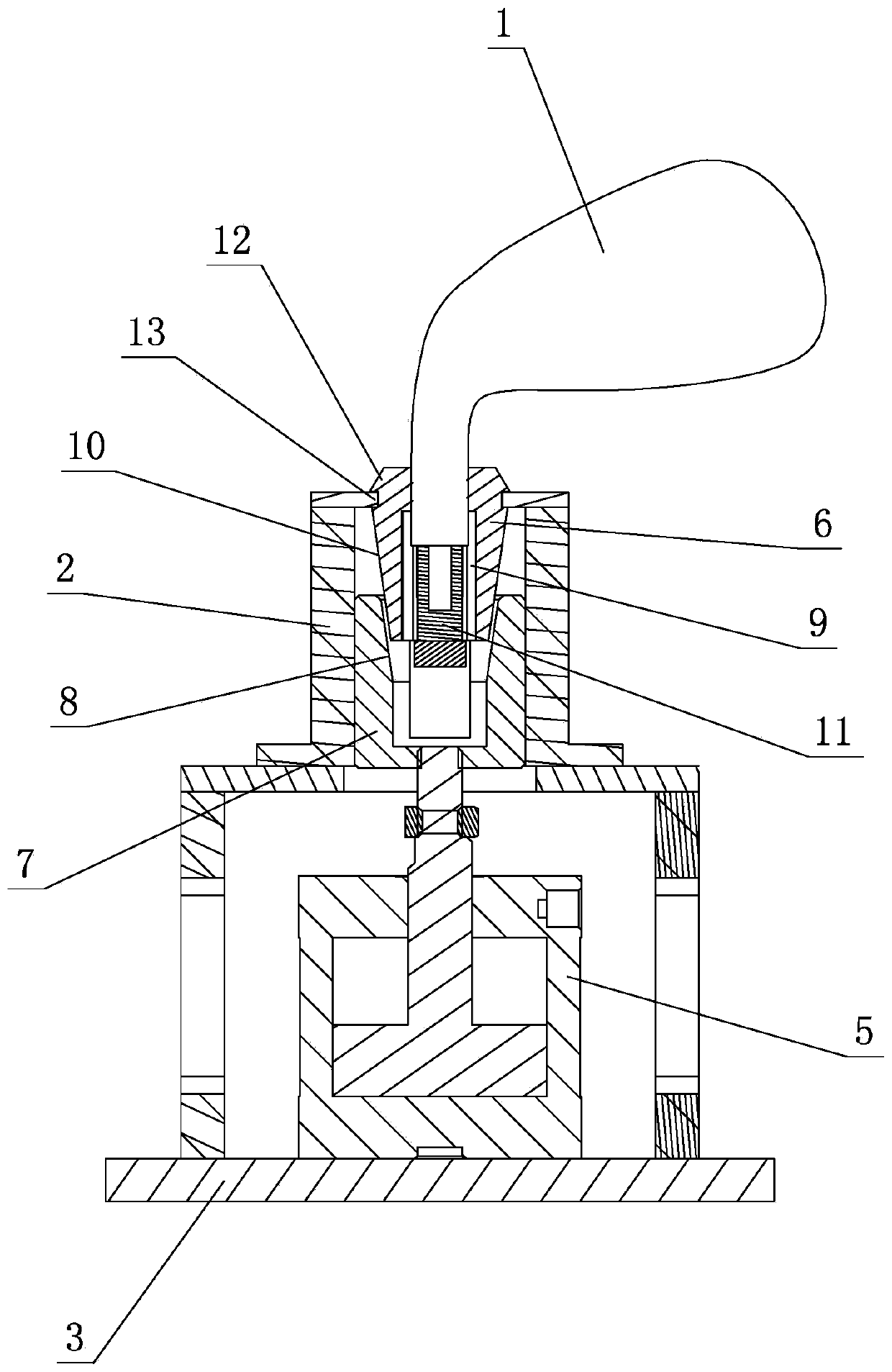

[0019] see figure 1 , figure 2 , the golf head clamping jig includes a ball head to be processed 1, a jig body 2 and a fixed base 3, the ball head to be processed 1 is placed on the jig body 2, and the jig body 2 is arranged on the fixed base 3, The fixed base 3 is also provided with a rough positioning mechanism and a push cylinder 5; wherein, the rough positioning mechanism is placed on the side of the jig body 2 and cooperates with the jig body 2 to realize the rough positioning of the ball head 1 to be processed , the push cylinder 5 is placed directly below the fixture main body 2, and is drivingly connected with the fixture main body 2, so as to realize the clamping and positioning of the ball head 1 to be processed.

[0020] Furthermore, a collet 6 and a slider 7 are arranged inside the jig body 2, wherein one end of the slider 7 is drivingly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com