Intermediate tank truck of continuous casting machine

A technology for tundish trucks and continuous casting machines, which is applied to casting equipment, casting molten material containers, lifting devices, etc. It can solve the problems of out-of-synchronization of the enlarged hydraulic control system, easy deformation of the tundish size, and increased construction costs. The effect of correcting and adjusting problems, improving bearing capacity, and reducing equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The present invention will be described in detail below in conjunction with the drawings and embodiments.

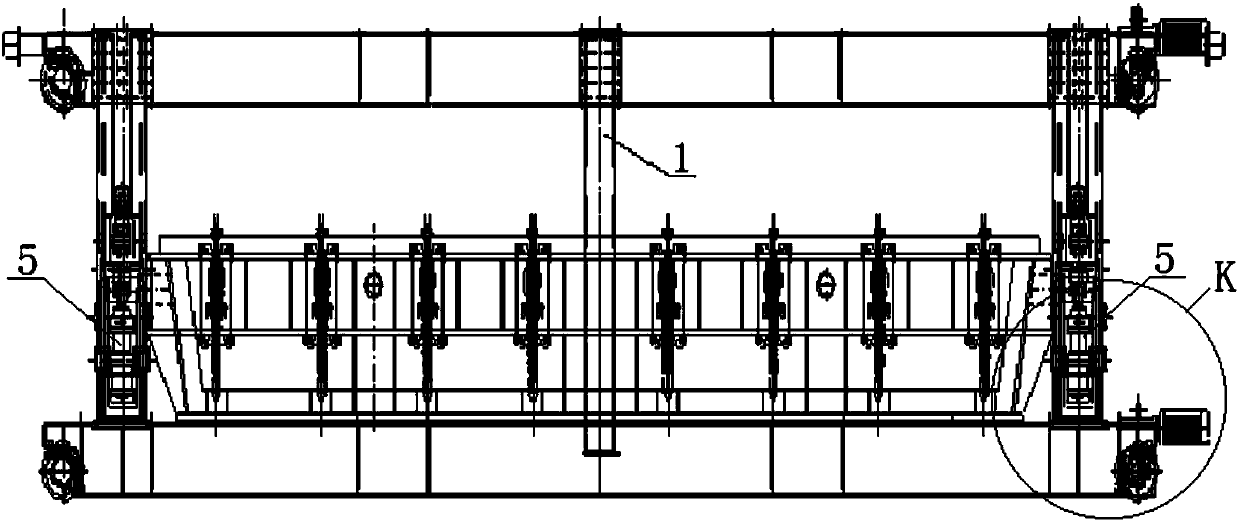

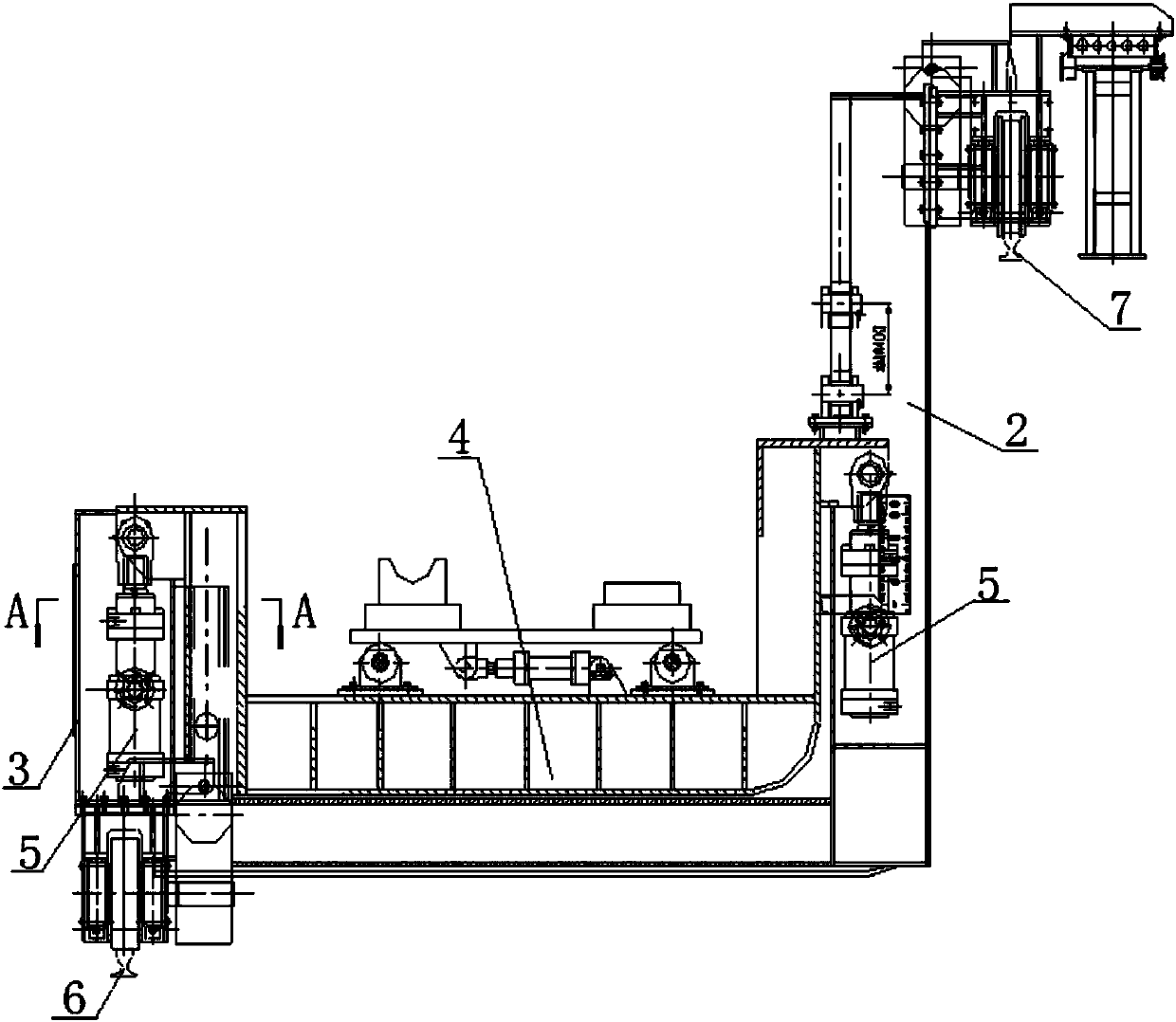

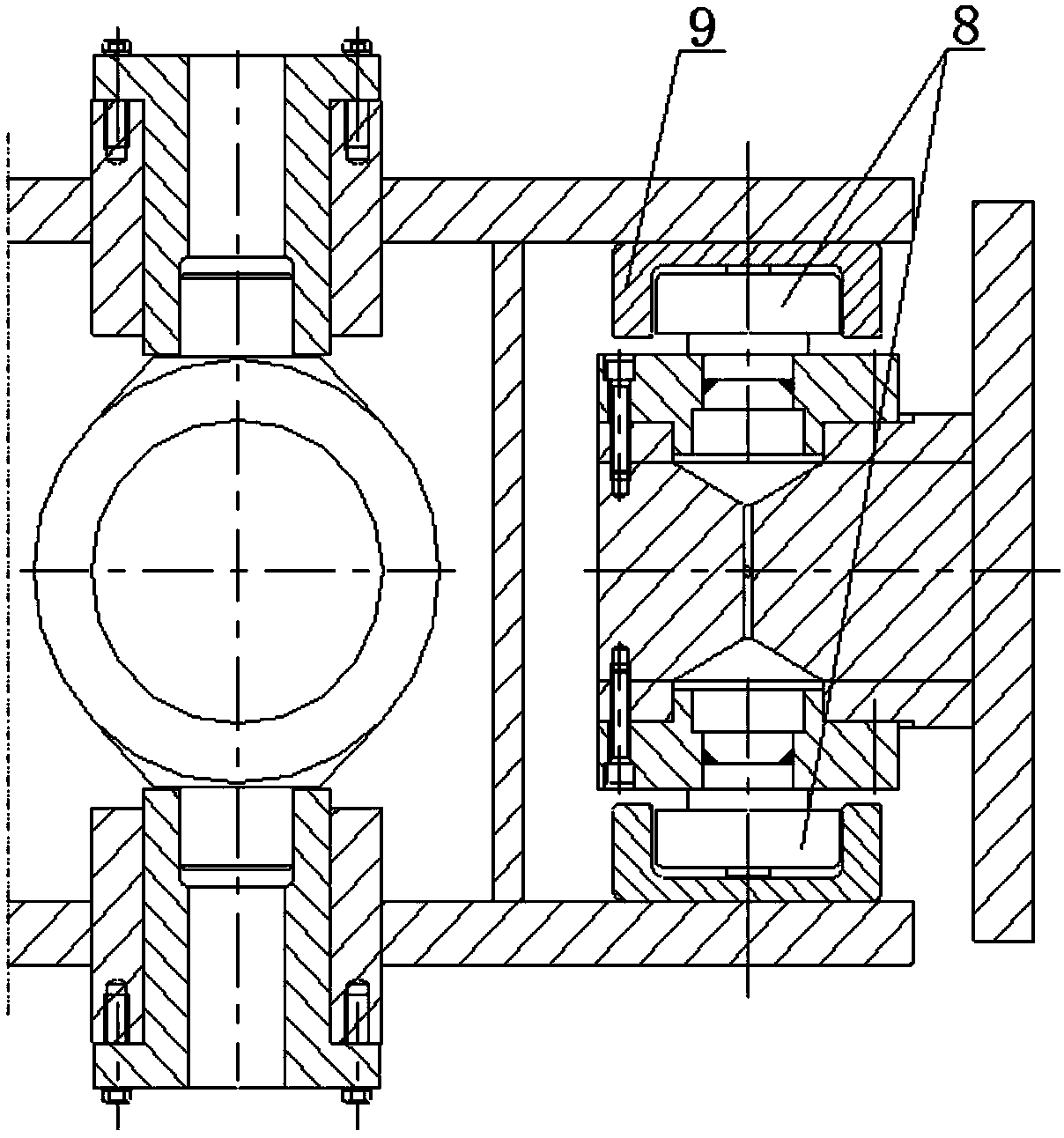

[0026] Reference Figure 1 ~ Figure 4 As shown, the tundish car of the continuous casting machine in an embodiment provided by the present invention includes a lifting mechanism 4, a low leg 3 and a high leg 2. The lifting mechanism 4 includes a bracket and four lifting cylinders 5, and the four lifting cylinders 5 are distributed Around the bracket, the low leg 3 and the high leg 2 are respectively arranged on both sides of the bracket, and the bracket is connected to the low leg 3 and the high leg 2 through the lifting cylinder 5, and both the low leg 3 and the high leg 2 are in the vertical direction There are guide grooves, and guide wheels 8 are arranged on both sides of the bracket. The guide wheels 8 are fixed on the bracket through rolling bearings. The guide wheels 8 are arranged in the guide groove and can move up and down along the guide groove; the interm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap