Nitrogen and phosphorus removal MBR integrated device using submerged blower and sludge return

A technology for sludge return, nitrogen and phosphorus removal, applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc. Quantity is not easy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

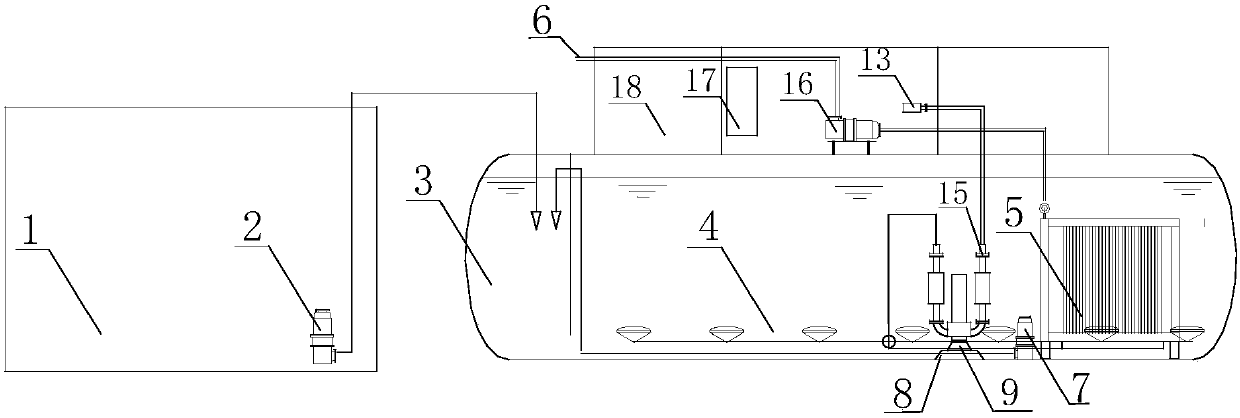

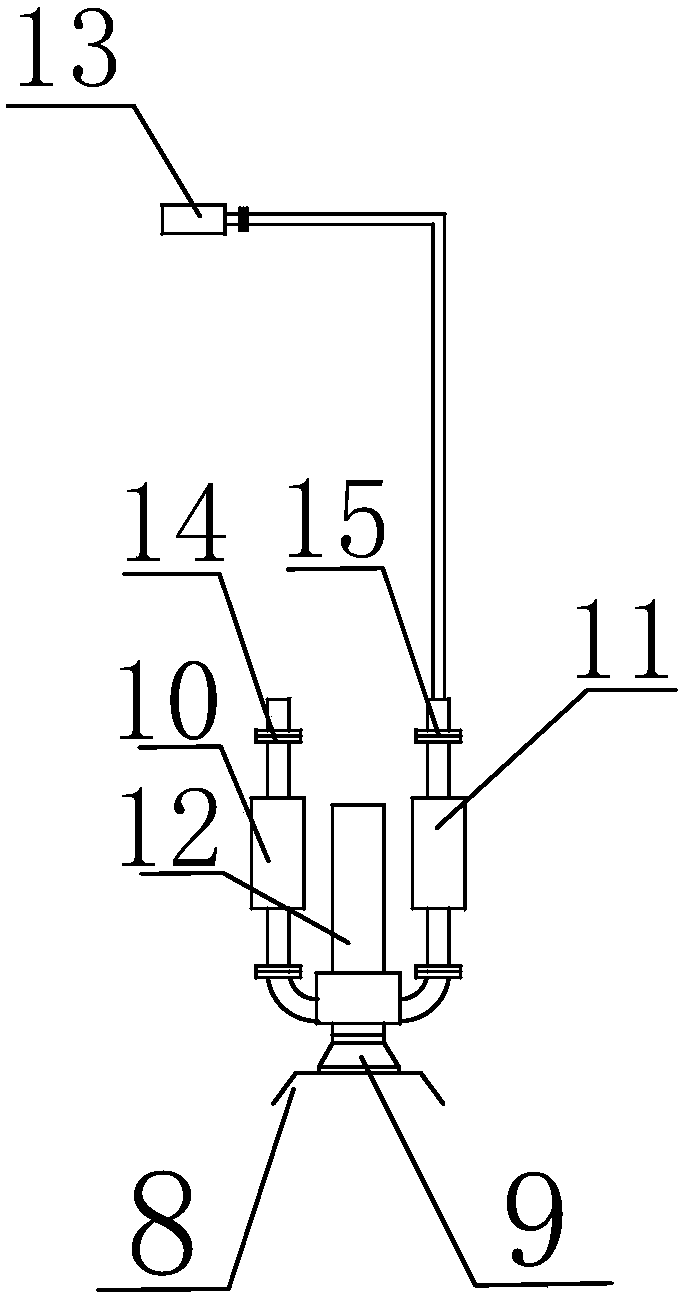

[0015] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, an MBR integrated equipment that uses submerged fans and sludge return to realize denitrification and phosphorus removal includes a regulating tank 1 connected to the sewage pipe network. The water outlet is connected, and the opening at the bottom of the water outlet dividing plate of the anoxic zone flows into the aerobic zone 4, and the water flow in the aerobic zone enters the membrane zone 5 through advection, and the water outlet of the membrane zone is connected to the self-priming pump 16 through a pipeline. The water outlet of the self-priming pump is connected to the final discharge pipe 6 through a pipeline, the sludge return pump 7 at the front end of the membrane area is connected to the anoxic area, and the aerobic area and the membrane area are respectively connected to the submerged fan. The air outlet is aerated. The submerged fan is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com