Variable-capacity washing-machine barrel capable of achieving independent washing and independent control and washing machine

A technology for washing machines and laundry cabins, which is applied to washing machines with containers, other washing machines, washing devices, etc., which can solve problems such as the impact of the balance of the barrel, dirt storage, and easy knotting of clothes, so as to improve the effect of water saving, The effect of increasing volume and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

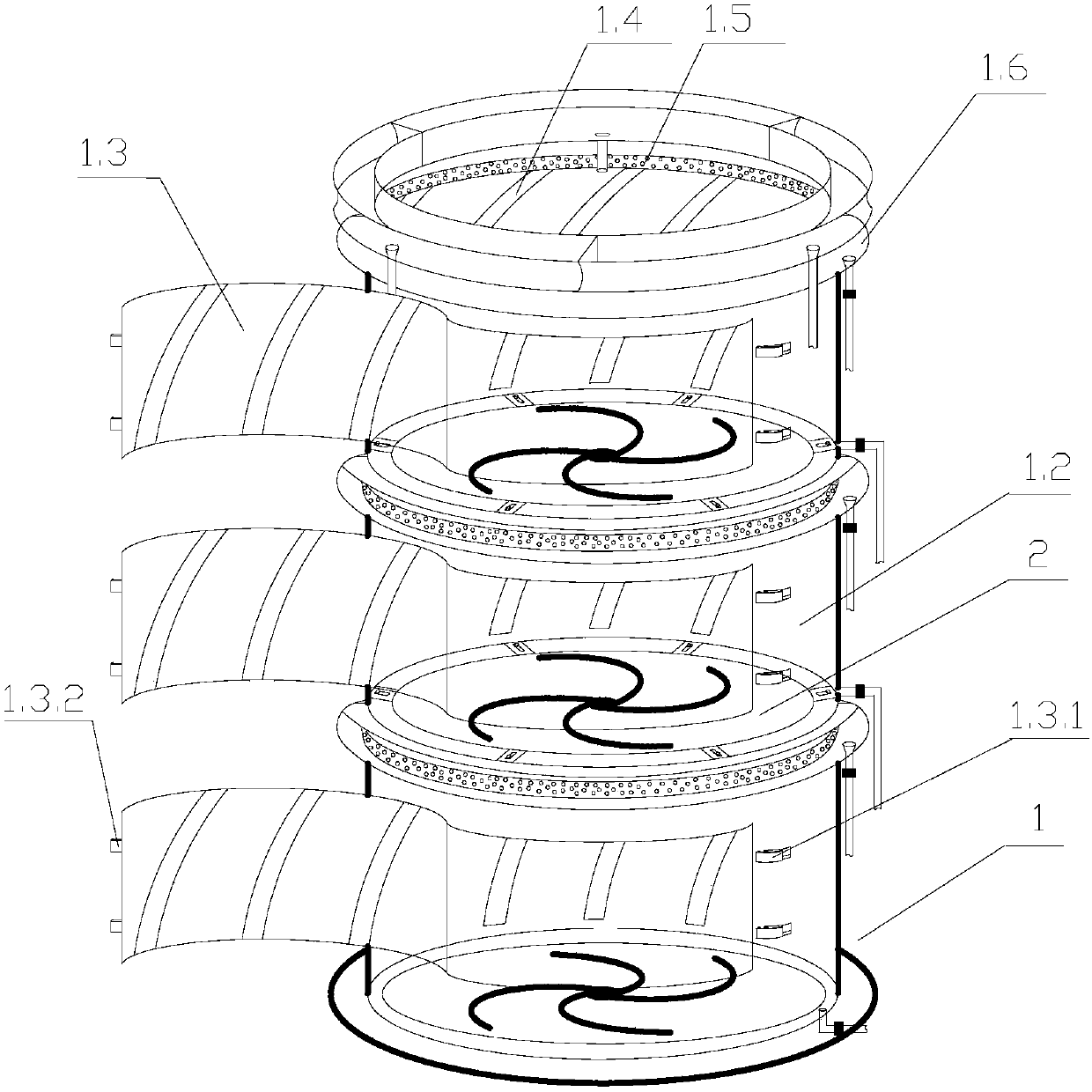

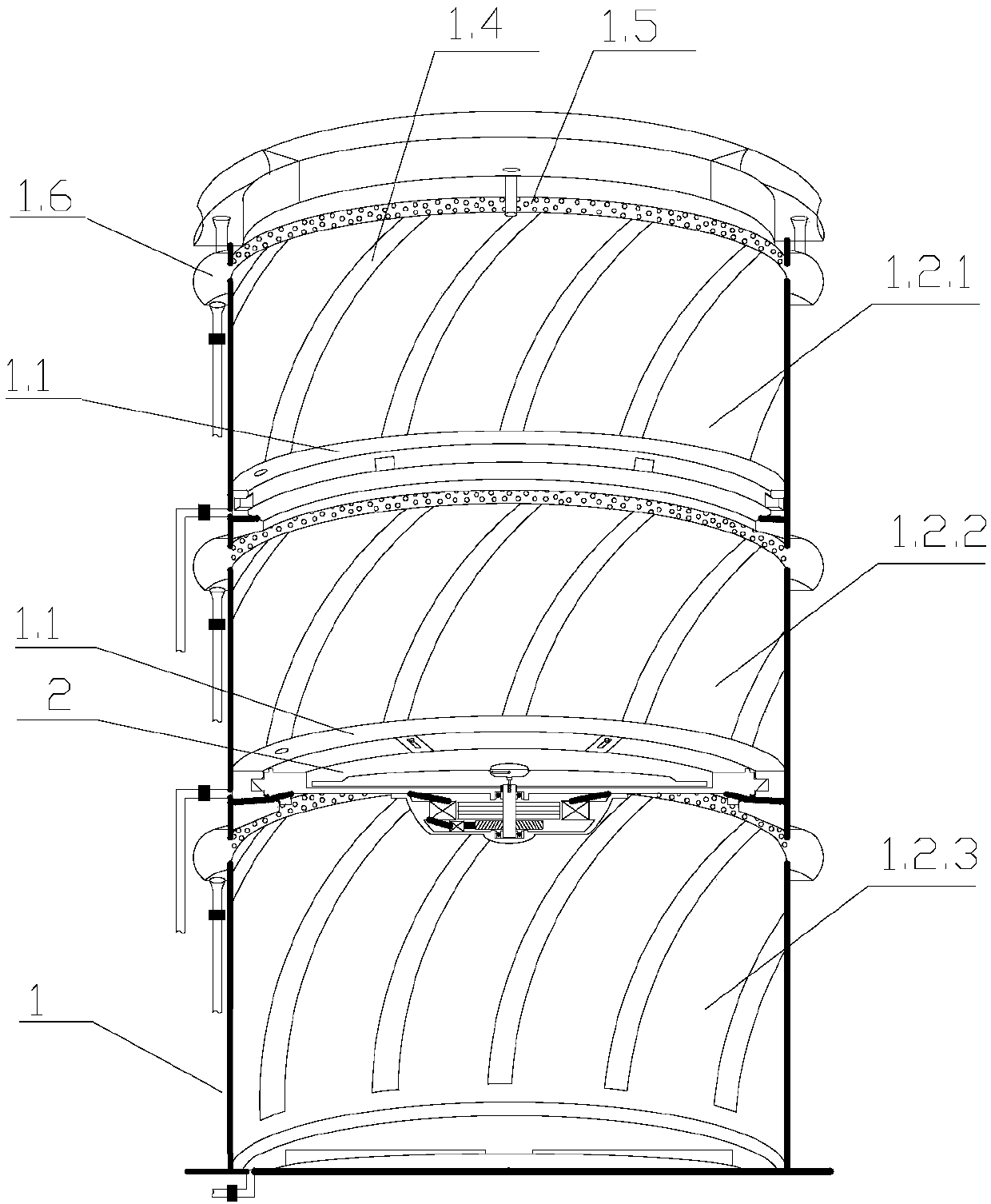

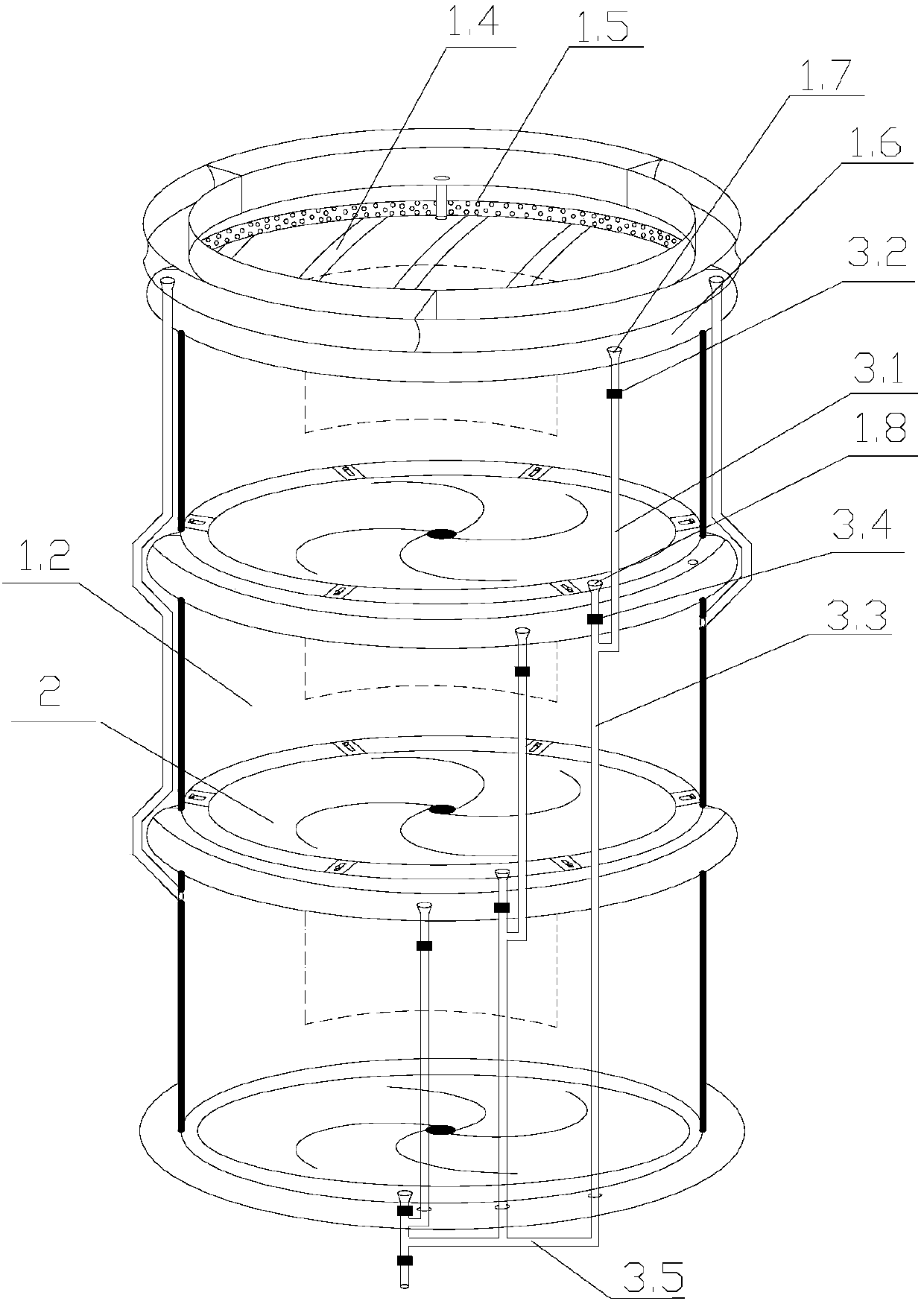

[0060] figure 1 and 2 The shown variable volume washing machine barrel that can be washed separately and controlled separately includes a barrel body 1 and two detachable electric pulsator discs 2 . Two annular mounting seats 1.1 are arranged on the inner wall of the bucket body 1, and the largest laundry space can be obtained without installing the pulsator disc 2. When one or two detachable electric pulsator discs 2 are installed as required, the The bucket body 1 can be divided into two or three laundry compartments 1.2 along the vertical direction. Such as figure 2 As shown, the bucket body 1 is separated by two detachable electric pulsator discs 2 into upper, middle and lower layers of independent laundry cabins 1.2, that is, the upper laundry cabin 1.2.1 and the middle laundry cabin 1.2.2 , Laundry cabin 1.2.3 on the ground floor. The side wall of the barrel body of each laundry compartment 1.2 is respectively provided with a laundry compartment door 1.3, the barrel...

Embodiment 2

[0074] Such as Figure 10 As shown, a variable volume washing machine with separate washing and separate control includes the bucket of the variable capacity washing machine with separate washing and separate control described in Embodiment 1.

[0075] The washing machine also includes a drainage device 3 , a water supply device 4 , a washing machine shell 5 , a braking device 7 , a controller 8 and a driving motor 9 .

[0076] The laundry compartments 1.2 on each floor are independently connected to the drainage device 3 and the water supply device 4 . The drainage device 3 includes an upper drain pipe 3.1, an upper drain valve 3.2 installed on the upper drain pipe 3.1, a lower drain pipe 3.3, a lower drain valve 3.4 installed on the lower drain pipe 3.3, a main drain pipe 3.5, and a drain valve installed on the lower drain pipe 3.5. The total drain valve 3.6 on the top, the drainage groove 3.7 connected with the total drain pipe 3.5, and the drain port 3.8.

[0077] The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com