Casing drilling system and casing drilling method

A casing drilling and casing technology, applied in the field of casing drilling system and casing drilling, can solve the surrounding soil pollution and other problems, and achieve the effect of avoiding pollution of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

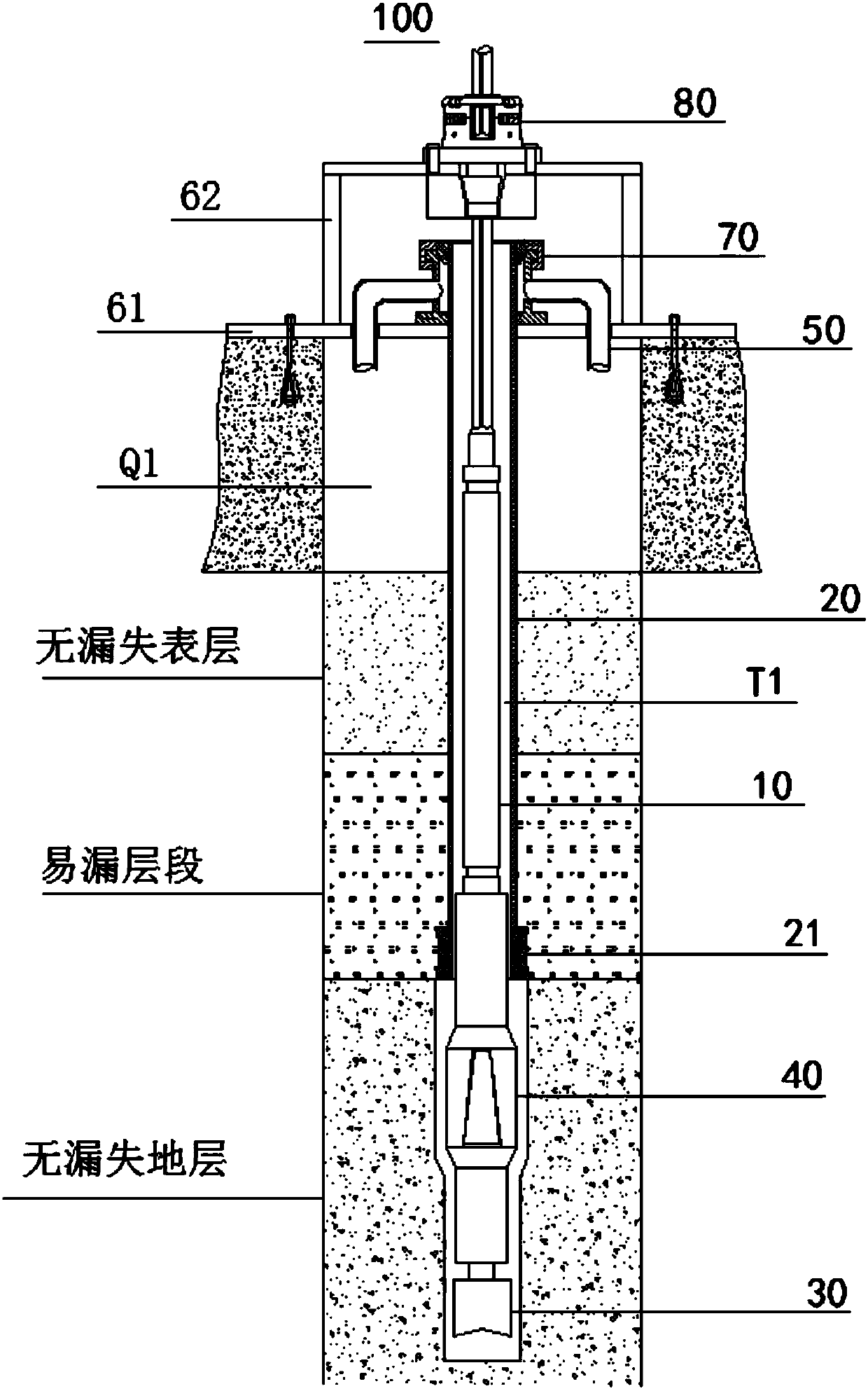

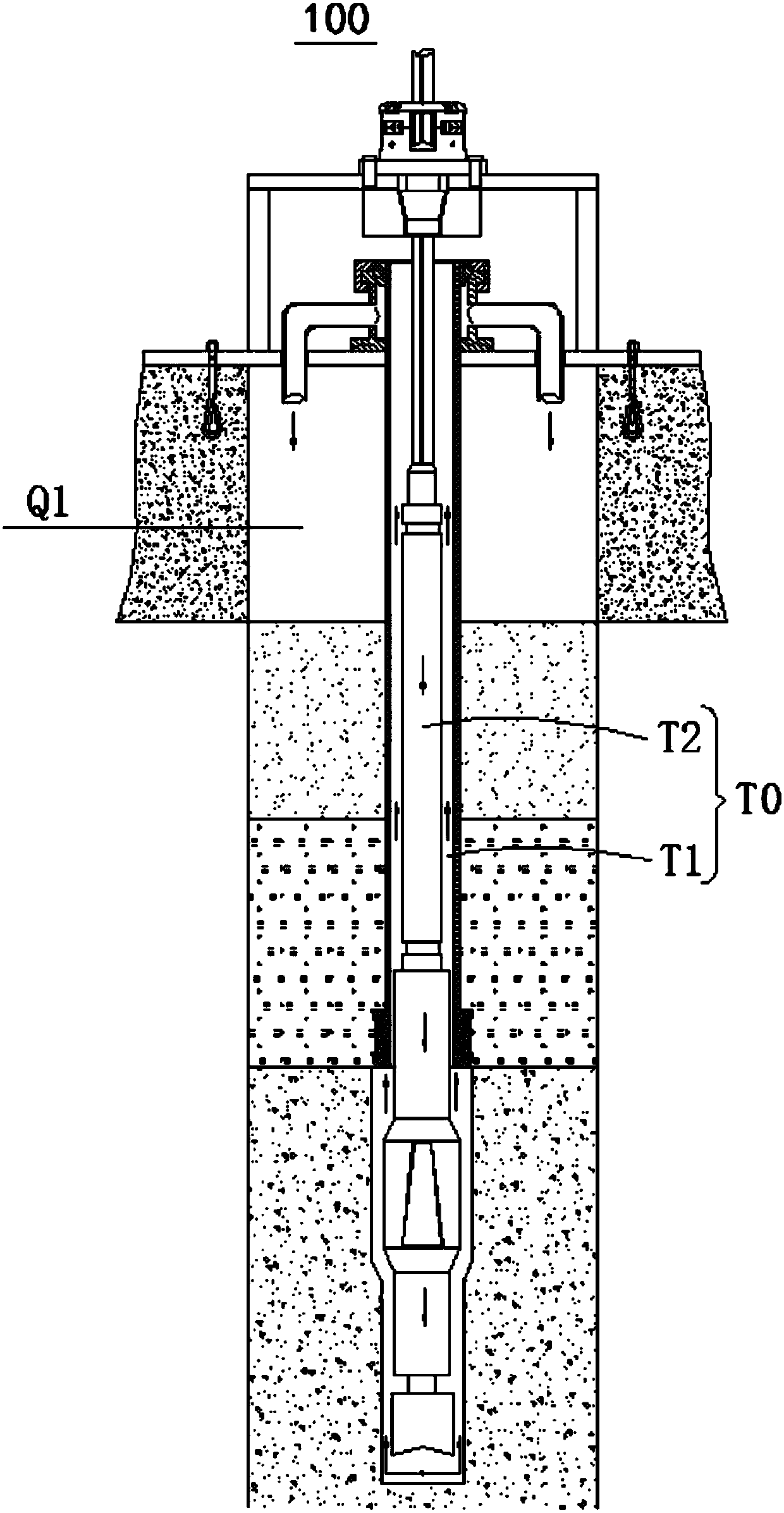

[0039] figure 1 It is a structural schematic diagram of the casing drilling system 100 in the embodiment of the present invention. See figure 1 , The casing drilling system 100 of the embodiment of the present invention includes a screw drilling tool 10, the lower end of the screw drilling tool 10 is connected with a drill bit 30 for drilling and a reamer 40 for reaming to form an internal drive system for driving downhole. A casing 20 is provided at intervals outside the screw drilling tool 10, and the screw drilling tool 10 is isolated from the well wall of the environment. A channel T1 is formed at intervals between the casing 20 and the screw drilling tool 10 . The inner flow channel T2 for supplying drilling fluid inside the screw drilling tool 10 communicates with the channel T1 at the lower end to form a fluid circulation T0. The casing 20 is driven to rotate by the external drive system, and the rotation of the casing 20 can change the resistance of the lower casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com