Vertical biomass combustion furnace and fruit and vegetable drying machine using same as heat source

A biomass burning furnace and burning furnace technology, applied in dryers, drying, combustion methods and other directions, can solve the problems of insufficient combustion of biomass particles, easy to produce coking, slagging, and low fuel utilization rate, etc. The effect of ensuring stability and continuity, avoiding combustion slagging, and improving combustion utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

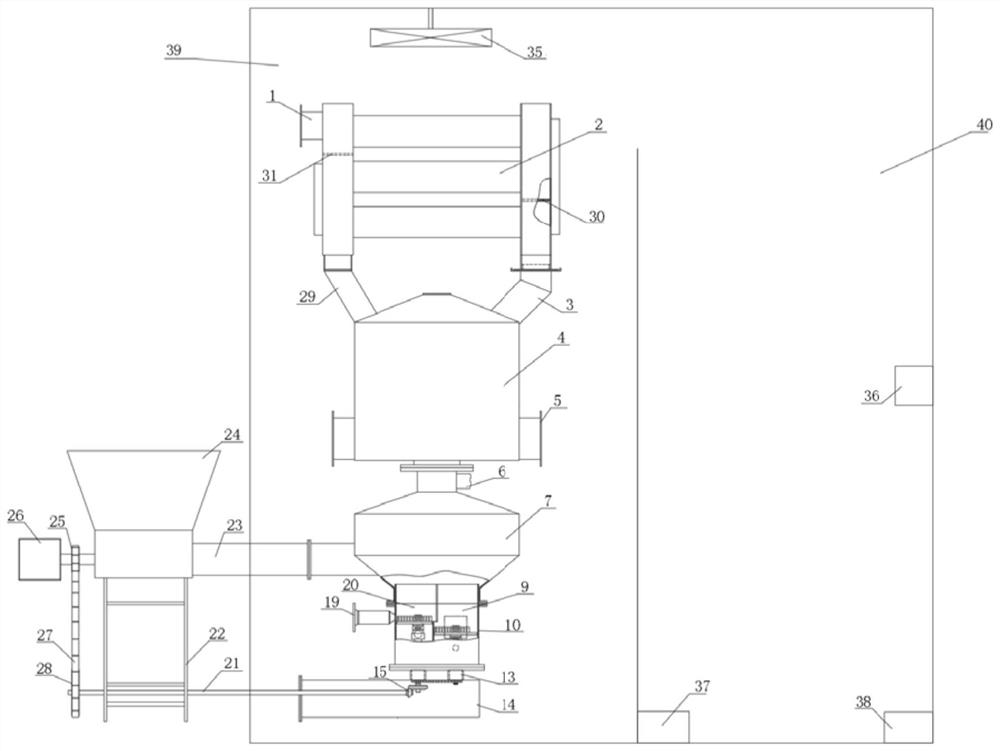

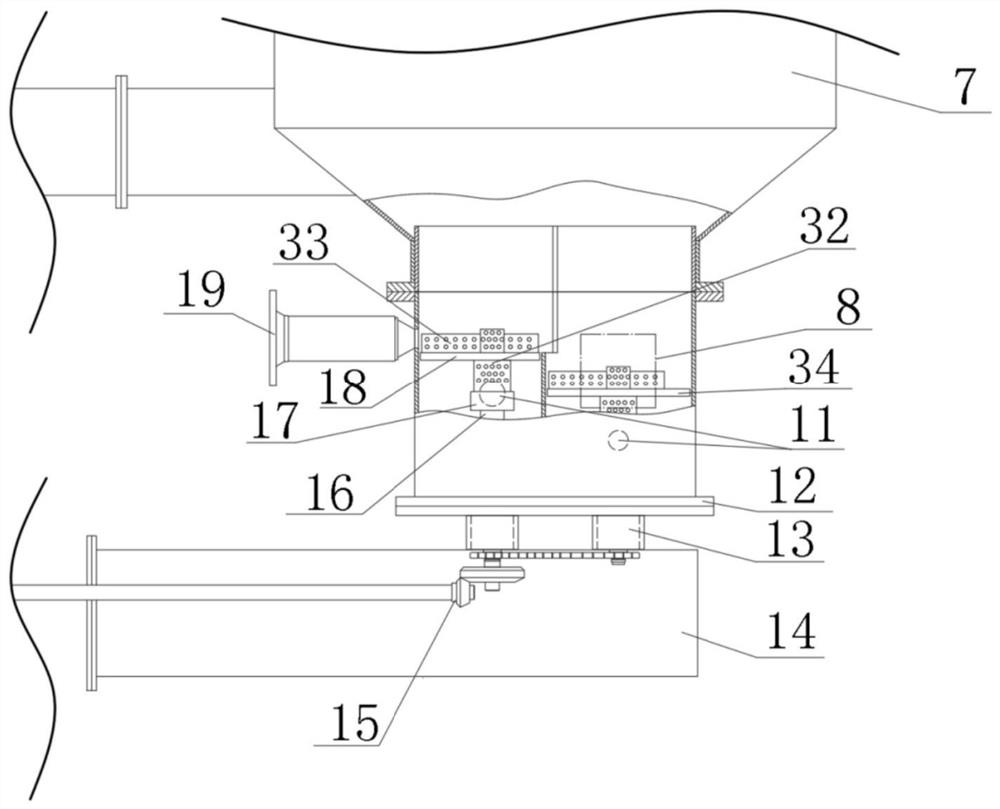

[0049] The present invention provides a specific embodiment of a fruit and vegetable dryer, which includes a fruit and vegetable dryer using a vertical biomass combustion furnace as a heat source.

[0050] Described dryer comprises heat source chamber 39 and drying chamber 40, and described heat source chamber 39 is provided with vertical biomass burner, and the radiator 2 of vertical biomass burner conducts the heat that the burner produces to air , the heat source chamber 39 communicates with the drying chamber 40, and the heated air is transported from the heat source chamber to the drying chamber for heating and drying the material to be dried. The drying room is set by an intelligent controller, which can detect the temperature and temperature of the drying room, and control the dehumidification device to dehumidify the drying room.

[0051] In an embodiment of the present invention, the heat source chamber 39 contains a vertical biomass combustion furnace. The vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com