Lifting appliance special for bridge type crane

A bridge crane and spreader technology, which is applied in the direction of walking bridge cranes, cranes, load blocks, etc., can solve the problems of low efficiency, shortened service life, and increased wear of bridge cranes, and achieves simple suspension operation, The effect of increasing service life and accelerating work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

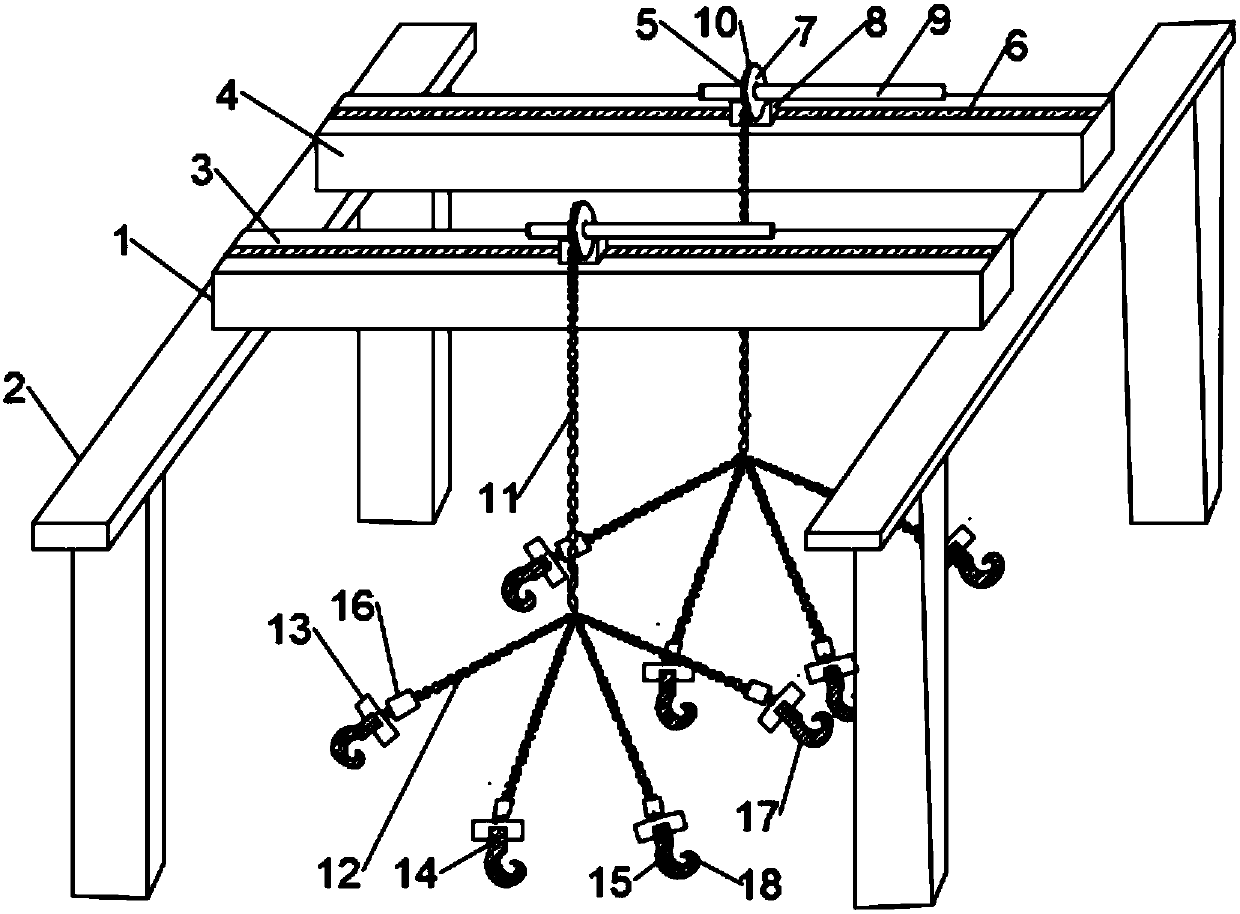

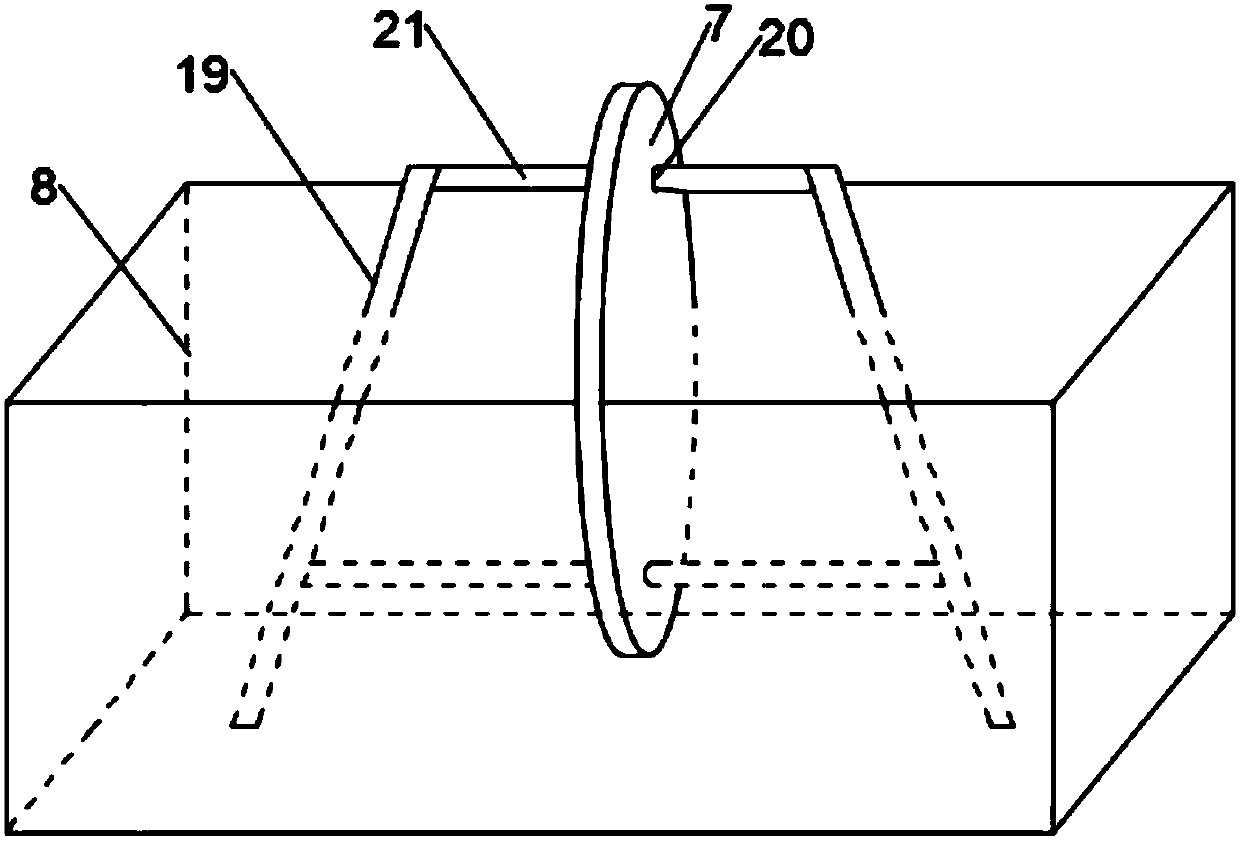

[0023] Such as figure 1 with figure 2 As shown, it includes a bridge 1 and a viaduct 2. The bridge 1 is set directly above the viaduct 2. The bridge 1 can move longitudinally along the viaduct 2. The bridge 1 includes a main girder 3 and a secondary girder 4. The beam 3 and the auxiliary beam 4 are both box-type structures. The upper surfaces of the main beam 3 and the auxiliary beam 4 are provided with a traction device 5, and the traction device 5 includes a rail 6 and a reel 7, and the rail 6 is welded to On the upper surface of the main beam 3 and the sub-beam 4, a slider 8 is provided above the rail 6. The slider 8 has a hollow structure, and the slider 8 can follow the rail under the control of the control system. 6 accurately move laterally to transport the material to the desired position. The reel 7 is arranged at the upper end of the slider 8, and the slider 8 moves laterally along the rail 6 above the rail 6, thereby driving the reel 7 along The rail 6 moves latera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com