Target material, forming method of target material, target material assembly and forming method of target material assembly

A target and component technology, which is applied in the field of target components and its formation, and the target and its formation, can solve the problems of increasing the thickness of the target and poor uniformity of sputtering film formation, so as to improve the uniformity, increase the life, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

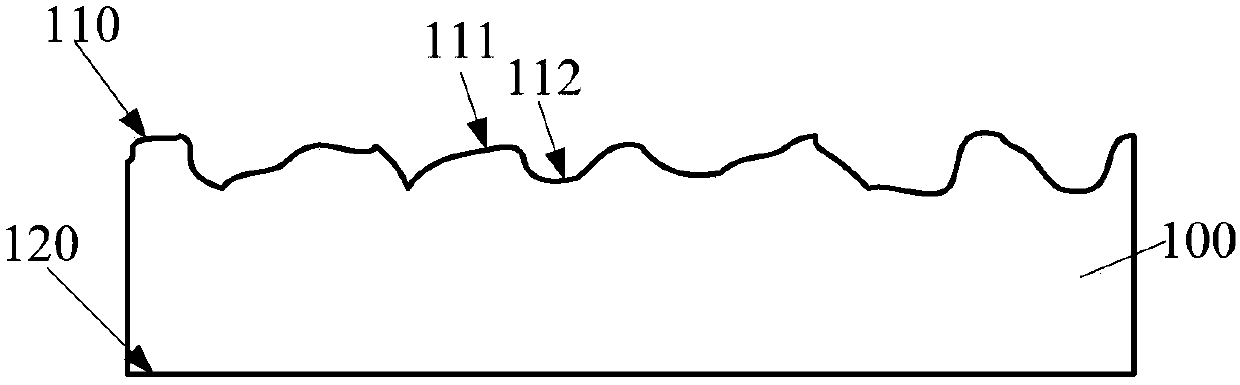

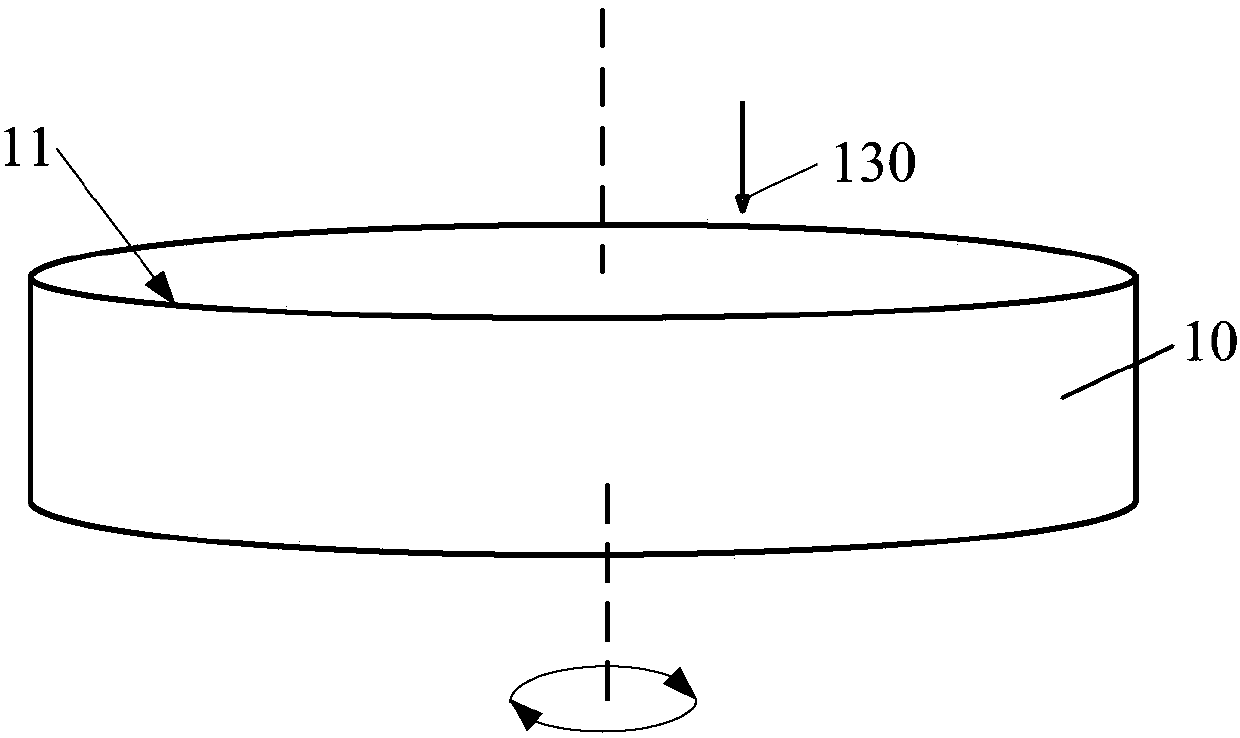

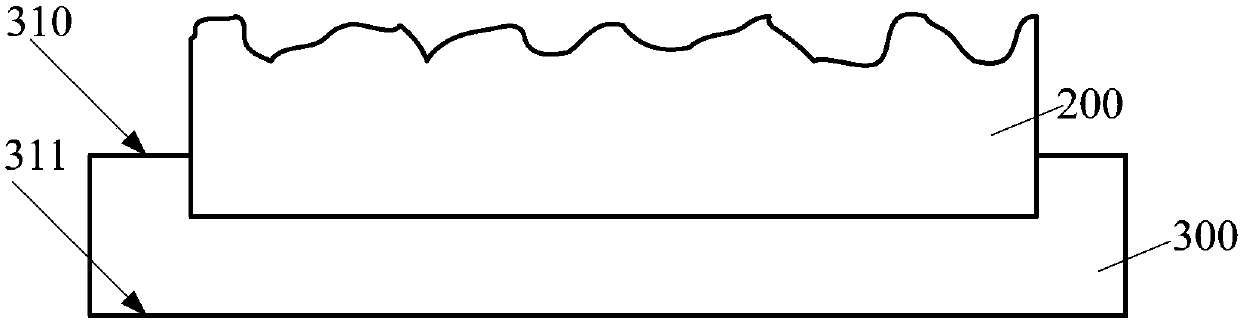

[0029] As mentioned in the background art, it is necessary to propose a more optimized design of the sputtering surface of the target.

[0030] The service life of the target can be extended by increasing the thickness of the target, but in the later stage of sputtering with the target, the uniformity of sputtering film formation is poor.

[0031] After research, it is found that the reason is that the distribution of the magnetic field strength in the sputtering chamber is different during the sputtering process, and the sputtering surface of the target is flat, so as the sputtering process progresses, the area with stronger magnetic field intensity corresponds to The sputtered surface of the sputtered surface will form premature pits. And as the thickness of the target increases, the depth of the pits formed on the sputtering surface corresponding to the region with stronger magnetic field strength increases in the later stage of sputtering. At the same time, the target mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com