Drop test equipment, method and device

A technology of testing equipment and equipment, applied in the direction of measuring devices, impact testing, testing of machines/structural components, etc., can solve problems such as inaccurate drop testing, achieve the effect of avoiding the loss of acceleration and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

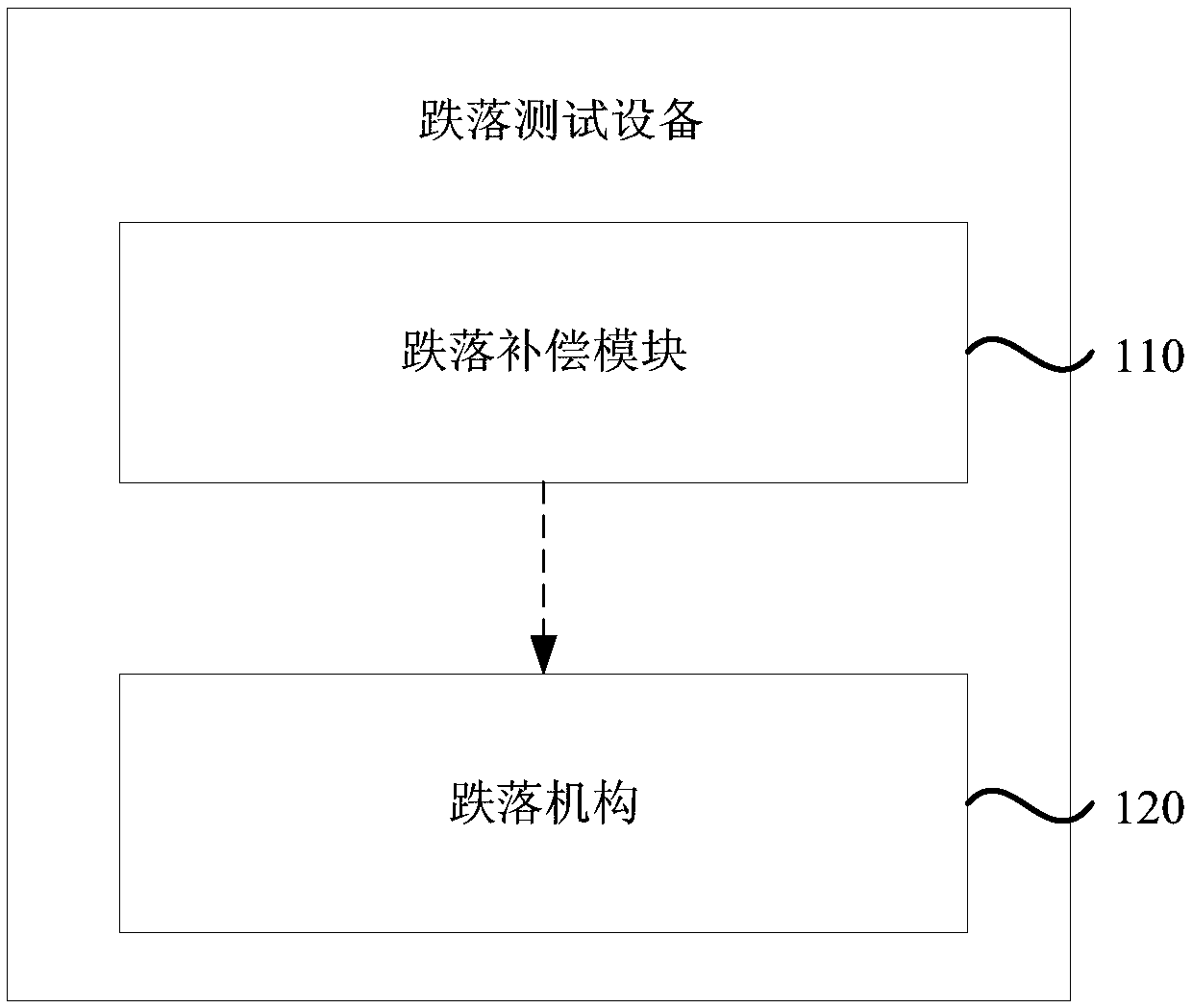

[0064] figure 1 A schematic diagram of the structure of a drop test device provided in Embodiment 1 of the present invention. This embodiment is applicable to the situation where the drop test device is used to perform acceleration compensation during the drop test process. The device can be implemented in the form of software and / or hardware .

[0065] The device in Embodiment 1 of the present invention specifically includes: a drop compensation module 110 and a drop mechanism 120 .

[0066] The drop mechanism 120 is used to drive the test product to fall freely downward during the drop test.

[0067] Preferably, the drop mechanism further includes: a fixing unit;

[0068] A fixing unit is used to fix the test product at a set test angle, so as to realize the directional drop test of the test product;

[0069] Wherein, the fixing unit includes: a clip-type fixing unit, and / or a suction cup-type fixing unit.

[0070] Specifically, during the product drop test process, the ...

Embodiment 2

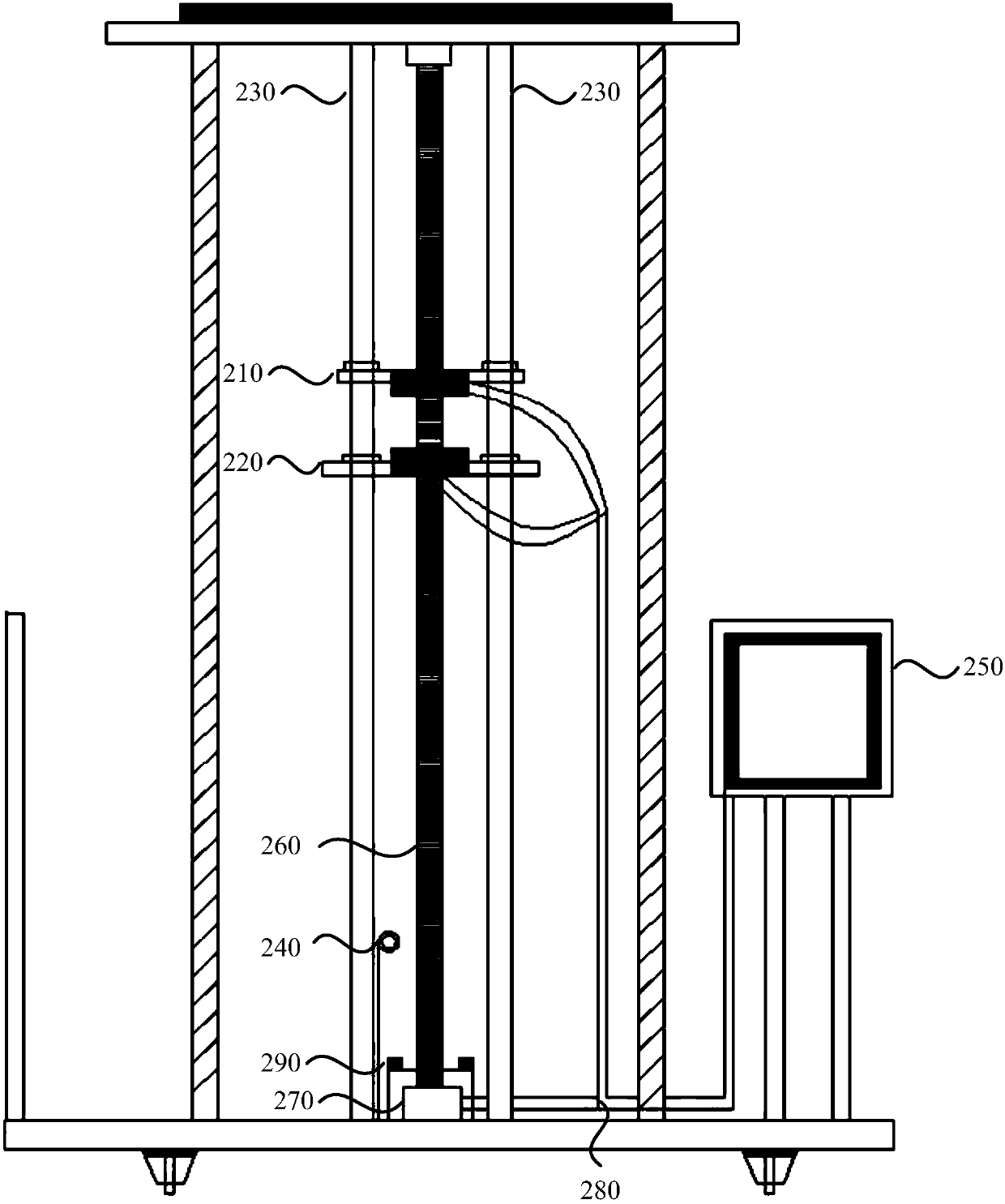

[0076] figure 2 A schematic structural diagram of a drop test device provided in Embodiment 2 of the present invention. Embodiment 2 of the present invention is optimized on the basis of Embodiment 1, specifically the further optimization of the structure of the drop test device, as shown in figure 2 As shown, the second embodiment of the present invention specifically includes: a drop compensation module 210, a drop mechanism 220, a vertical slide rail 230, a speed detection sensor 240, a controller 250, a vertical lifting component 260, a motor 270, a control line 280 and a support Part 290.

[0077] The drop compensation module 210 is arranged on the upper part of the drop mechanism, and is used to apply a downward force to the drop mechanism when the drop mechanism begins to fall freely, so as to perform acceleration compensation on the drop mechanism, specifically including the first Magnetics, first rail kit and second rail kit to match the vertical rails.

[0078] T...

Embodiment 3

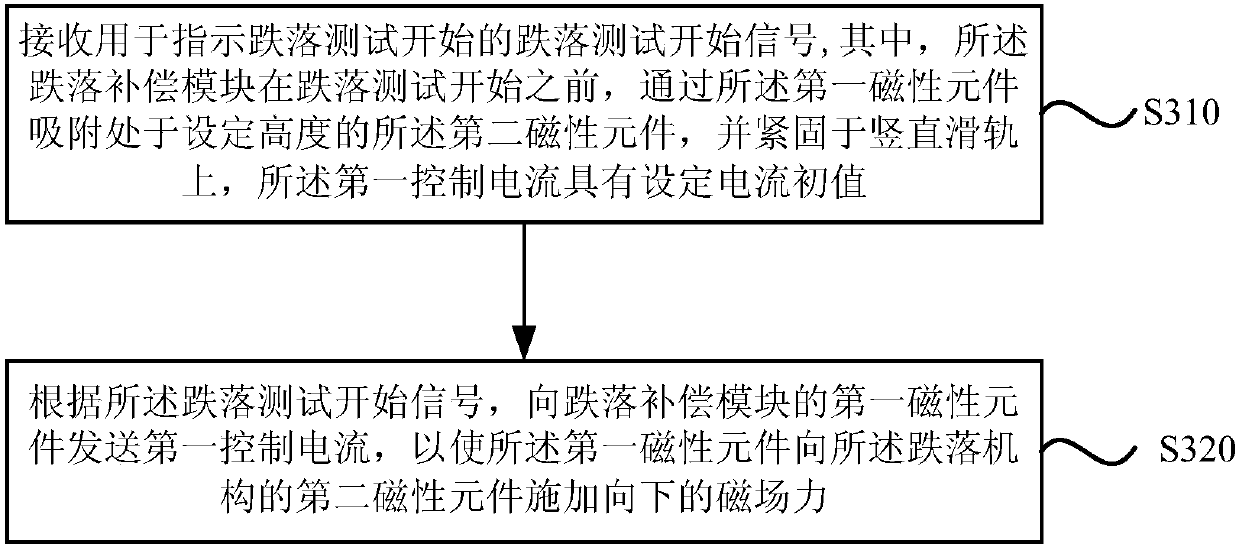

[0101] image 3 It is a flow chart of a drop test method provided by Embodiment 3 of the present invention. This embodiment can be applied to the drop test device provided by the embodiment of the present invention, and is suitable for the case where acceleration compensation is performed by the drop test device. This method can It is performed by a drop test device, which can be implemented in the form of software and / or hardware, and is generally integrated in the controller of the drop test equipment.

[0102] The method of the third embodiment of the present invention specifically includes:

[0103] S310. Receive a drop test start signal for instructing the start of the drop test.

[0104] S320. According to the drop test start signal, send a first control current to the first magnetic element of the drop compensation module, so that the first magnetic element applies a downward magnetic field force to the second magnetic element of the drop mechanism.

[0105] Wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com