Pit digging equipment

A technology of equipment and mobile trolley, which is applied in planting methods, digging/covering ditches, mixers, etc., can solve problems such as low work efficiency, crooked fruit tree saplings, and large-scale labor, so as to improve work efficiency and facilitate fertilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

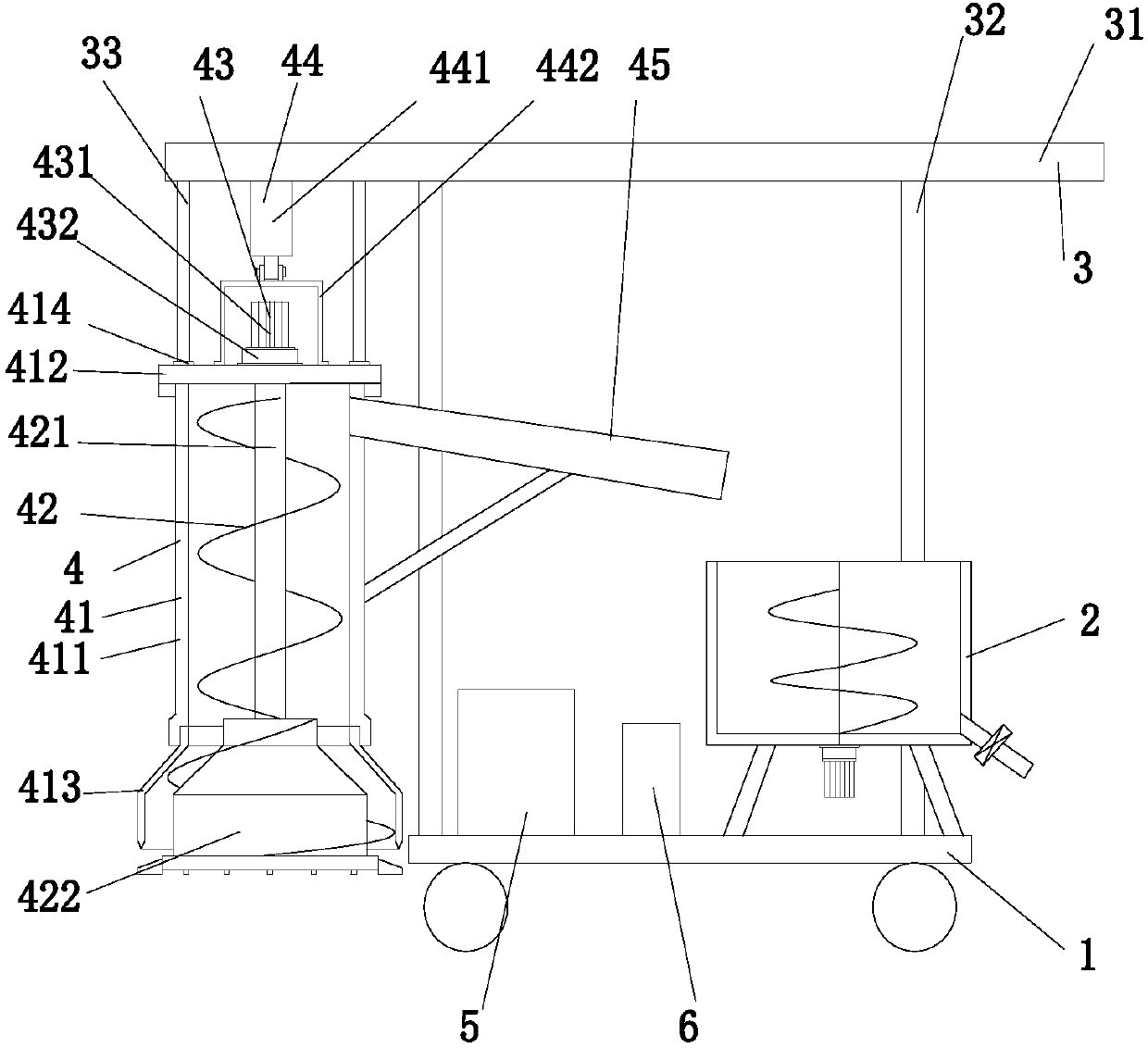

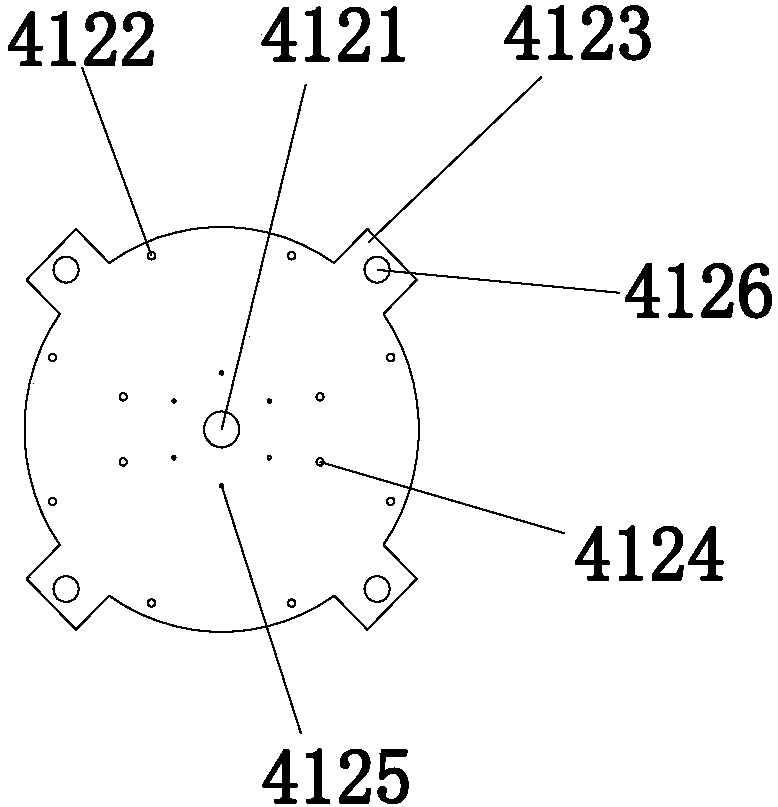

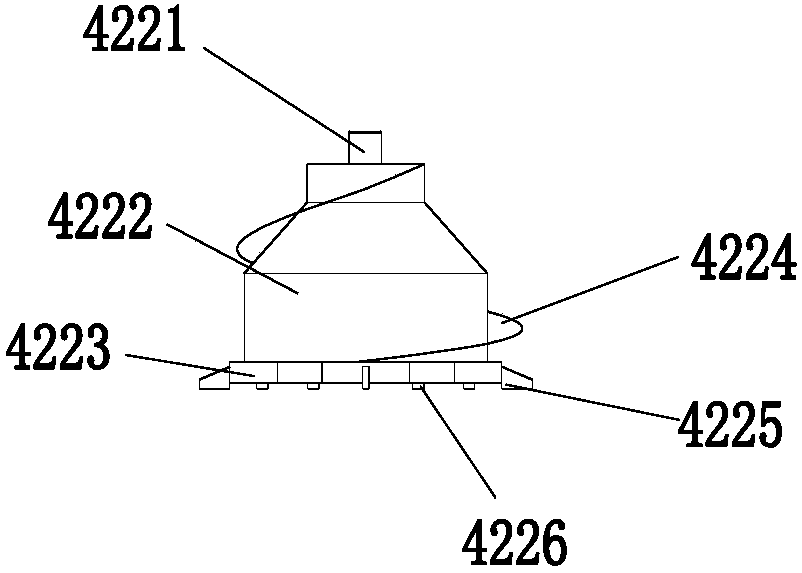

[0024] Such as Figure 1-3 As shown, a kind of pit digging equipment includes a mobile trolley 1, a stirring device 2 arranged on the mobile trolley 1, a frame body 3 arranged on the mobile trolley 1 and a The digging device 4 at the end of the mobile trolley 2, the frame body 3 includes a horizontal plate 31, a column 32 for fixing the horizontal plate 31 on the mobile trolley 1 and a guide rail arranged on the horizontal plate 31 33. The pit digging device 4 includes a cylinder body 41, a drilling mechanism 42 arranged inside the cylinder body 41, a driving mechanism 43 arranged outside the cylinder body 41 for driving the drilling mechanism 42 to drill, and a driving mechanism for driving the drilling mechanism 42 to drill. The propulsion mechanism 44 for the guide rail 33 of the cylinder 41 to move up and down, the drilling mechanism 42 includes a delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com