Tea tray device for automatically pouring tea

A tea tray and automatic technology, applied in beverage preparation devices, home appliances, applications, etc., can solve problems such as being too cumbersome and too simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

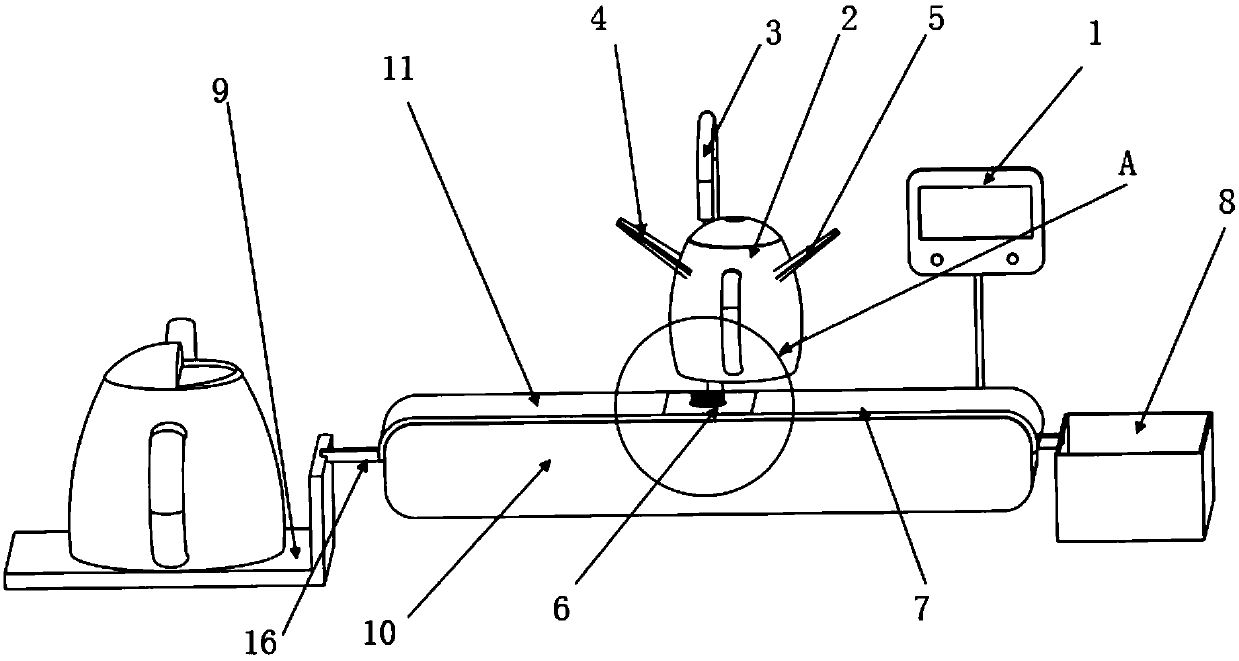

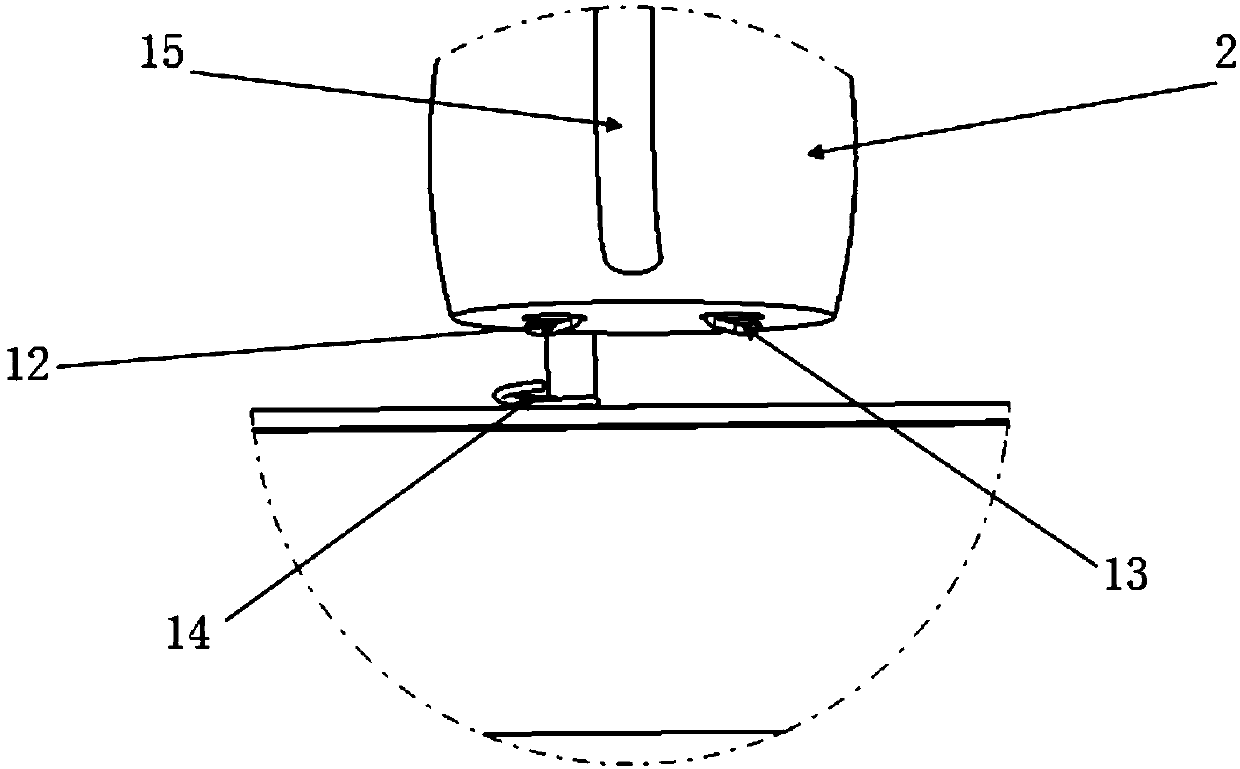

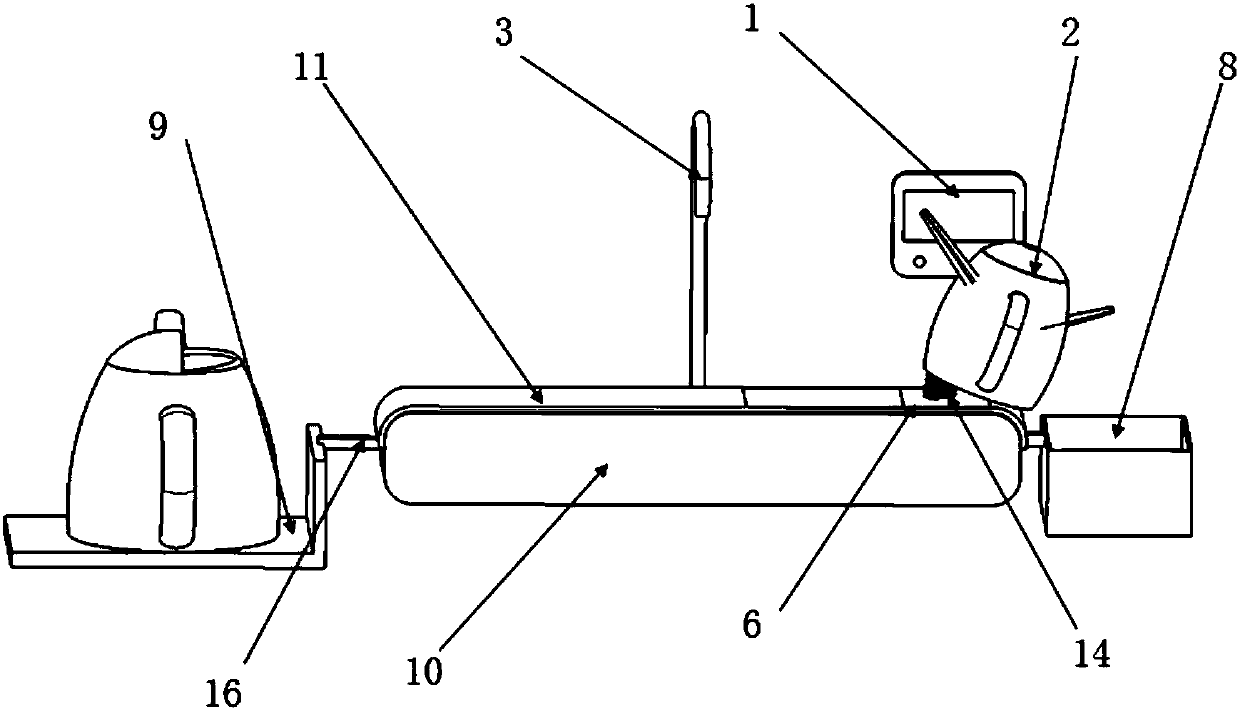

Embodiment 1

[0035] see figure 1 as well as figure 2 , a tea tray device for automatically pouring tea, comprising a support platform 10, a teapot 2, a water injection system 3 arranged on one side of the support platform 10, a transmission module, and a control terminal 1 electrically connected to the transmission module; wherein, the teapot 2 The first eccentric position of the bottom is provided with a first hook portion 12, and the plane where the handle 15 of the teapot 2 is located is a plane of symmetry, and the side of the body symmetrical to the first eccentric position is provided with a first water outlet 5; It includes a drive mechanism electrically connected to the control terminal 1, and a transmission part for transmitting the teapot 2. A groove (not shown in the figure) is provided at the position where the transmission part places the teapot 2, and an elastic element 14 is fixed in the groove. When pouring tea from the first water outlet 5 , the elastic element 14 is con...

Embodiment 2

[0042] This embodiment further improves the safety and reliability of the tea pouring process on the basis of Embodiment 1. The transfer module includes a first transfer module 7, an intermediate transfer module 6, and a second transfer module 11 that move independently. The first transmission module 7, the middle transmission module 6, and the second transmission module 11 are respectively provided with independent sub-drive mechanisms. part; the transmission part of the first transmission module 7 is arranged on the first end of the horizontal movement part and is not connected with the horizontal movement part, and the transmission part of the first transmission module 7 is provided with a first hanging ring near the groove (not shown in the figure shown), when pouring tea from the first water outlet 5, the first hanging ring is connected with the second hook part 13; The moving part is connected, and the transmission part of the second transmission module 11 is provided wi...

Embodiment 3

[0047] In this embodiment, the water injection system 3 is further improved on the basis of Embodiment 1 or Embodiment 2. The water injection system 3 is electrically connected to the control terminal 1 , and the control terminal 1 controls the water injection switch of the water injection system 3 .

[0048] Further, the water injection system 3 is provided with a water temperature adjusting device for adjusting the outlet water temperature, and the water temperature adjusting device receives the outlet water temperature signal sent by the control terminal 1 .

[0049] Further, the body of the teapot 2 is provided with a tea making type label, and the water injection system 3 is provided with an identification device for identifying the tea making type label. The identification device is electrically connected to the control terminal 1 and sends the identified information of the tea making type label to In the control terminal 1, the label of the type of brewed tea can be a tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com