An air-cooled steel ingot mold and its casting process

A steel ingot mold and air-cooling technology, which is applied in the field of steel ingot air-cooling process design for die casting production, can solve the problems of high safety factor requirements and the lack of wide application of water-cooled steel ingots, so as to improve production efficiency and shorten the crystallization time of steel ingots , Improve the effect of crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

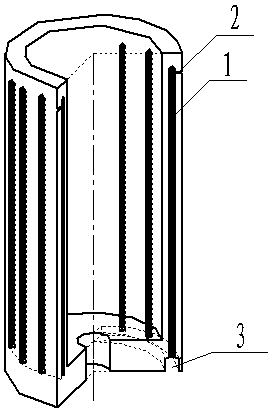

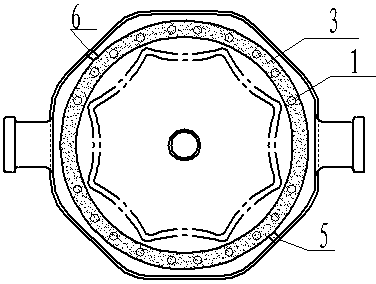

[0027] Embodiment 1: as figure 1 , 2 As shown, the present invention discloses an air-cooled steel ingot mold. Air guide holes 1 are opened and processed in the mold wall of the original steel ingot mold, and vent holes 2 are opened and processed on the outside of the steel ingot mold. Each vent hole 2 corresponds to a The air guide hole 1 is provided with an air guide groove 3 at the bottom of the original steel ingot mold. The air-introducing hole 4 communicated with the air-guiding groove 3, the air-introducing hole 4 is connected with the compressed air device through the connection device 7, so as to realize the influence of the compressed air on the crystallization process of the steel ingot.

[0028] The present invention is designed and modified on the basis of the existing steel ingot mould, that is, to drill ≥Ф40mm ventilation holes at 1 / 2 wall thickness of the ingot mold, the ventilation holes are evenly distributed along the circumference, and the hole spacing is ...

Embodiment 2

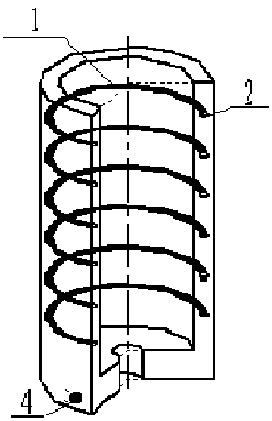

[0037] Embodiment 2: as image 3 As shown, an air-cooled steel ingot mold is directly embedded in the mold wall of the steel ingot mold when the steel ingot mold is cast. The device is connected with the compressed air device, and the compressed air directly intervenes in the crystallization process of the steel ingot through the air hole. When casting the ingot mold, a line pipe with a diameter of ≥Ф40mm is embedded in the casting sand mold in advance. After the ingot mold is cast, a through hole with a diameter of ≥Ф40mm is spirally distributed in the wall thickness of the ingot mold from bottom to top. For details, see image 3 .

[0038] The air guide pipe embedded in the mold wall of the steel ingot mold is a spiral air guide pipe. The spiral air duct is a helical tube with a diameter of ≥Ф40mm embedded in the casting sand mold in advance. The two ports of the helical tube are air-introduction holes and exhaust holes respectively. After the steel ingot mold is cast, 1 / 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com