Manufacturing process of high-speed steel for taps and taps

A manufacturing process, high-speed steel technology, applied in the direction of manufacturing tools, improving process efficiency, improving energy efficiency, etc., can solve the problems of unguaranteed service life, carbide aggregation and growth, and low grain bonding strength to achieve tool life Improvement, uniform composition and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

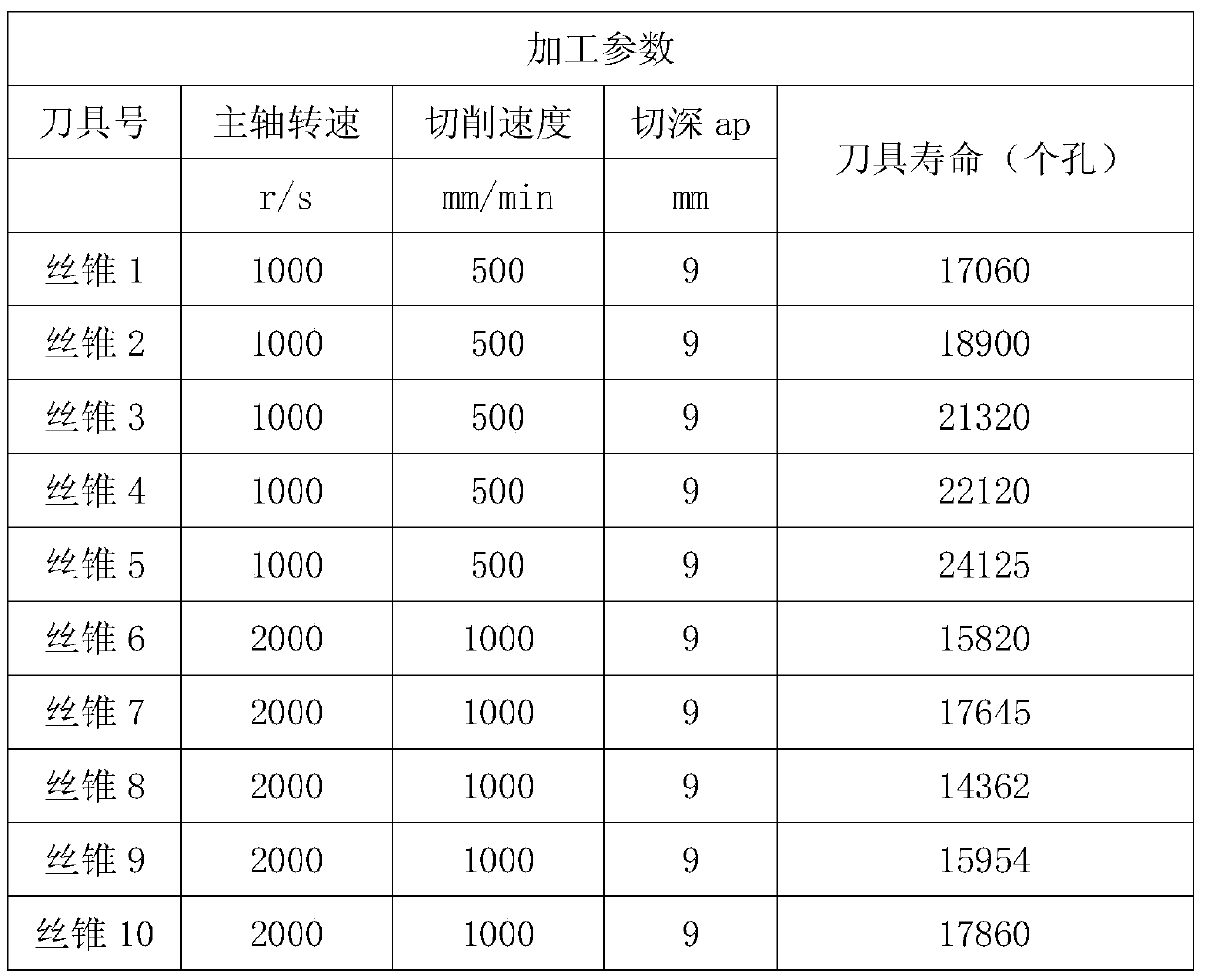

Image

Examples

Embodiment Construction

[0019] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments.

[0020] A special high-speed steel manufacturing process for taps, comprising the following steps,

[0021] Step S1, prepare raw materials according to the following weight percentages, C: 1.27%-1.35%, Mn: 0.5%-0.6%, Mo: 7.3%-8%, Cr: 3.5%-4%, W: 3%-3.5%, V: 2.8%-3.1%, the rest is Fe;

[0022] Step S2, put the mixed raw materials into a vacuum induction furnace, keep the vacuum degree in the vacuum induction furnace less than or equal to 2Pa, heat and melt the raw materials into a melt, and mix the melt in the vacuum induction furnace evenly, and then put The melt is cast into a steel ingot in a protective atmosphere, and the overall time is about 2.5 hours;

[0023] Step S3, the steel ingot formed in step S2 is treated by atmosphere-protected electroslag remelting, the temperature range of the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com