Aluminum alloy damping tower die-casting die

A technology for die-casting molds and shock-absorbing towers, applied in the field of aluminum alloy shock-absorbing tower die-casting molds, can solve the problems of low working efficiency of cooling pipelines and temperature-limiting pipelines, insufficient temperature-limiting protection of inserts, and low production efficiency. The effect of reducing the frequency of maintenance and inspection, avoiding the increase of the matching tolerance, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

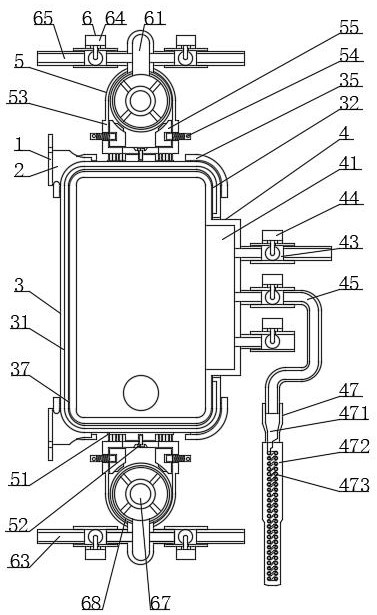

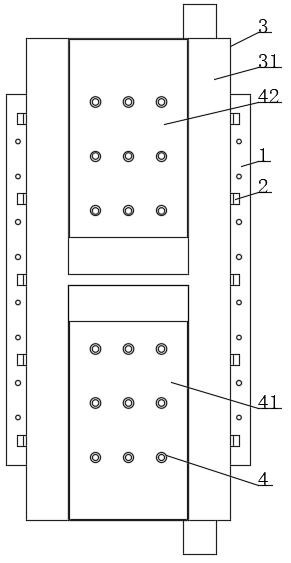

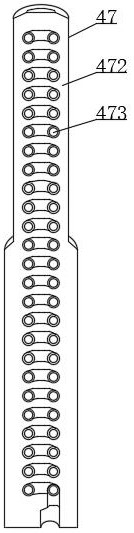

[0034] An aluminum alloy shock tower die-casting mold, comprising a perforated bottom plate 1, a bracket 2 is fixedly connected to the right end of the perforated bottom plate 1, a heat insulation partition mechanism 3 is fixedly connected to the right end of the bracket 2, and the inner side of the heat insulation partition mechanism 3 is clipped There is a heat storage mechanism 4, a positioning mechanism 5 is fixedly connected to the outer side of the heat insulation partition mechanism 3, and a cold storage mechanism 6 is sleeved on the inner side of the positioning mechanism 5.

[0035] refer to Figure 1-7 , the heat insulation partition mechanism 3 includes a heat insulation partition cover 31, the top and bottom of the left end of the heat insulation partition cover 31 are fixedly connected to the right end of the bracket 2, and the inside of the front end and the inside of the rear end of the heat insulation partition cover 31 are bonded with heat insulation The inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com