Reinforcing structure for vehicle tail light preventing vehicle body interference and manufacturing method thereof

A technology for strengthening structure and manufacturing method, applied in the field of auto parts, can solve the problems of time-consuming consumables and labor consumption, lampshade and lamp housing detachment, precision deviation, etc., so as to reduce maintenance costs and prevent The effect of disengagement and meeting aesthetic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but the present invention is not limited to the following specific embodiments.

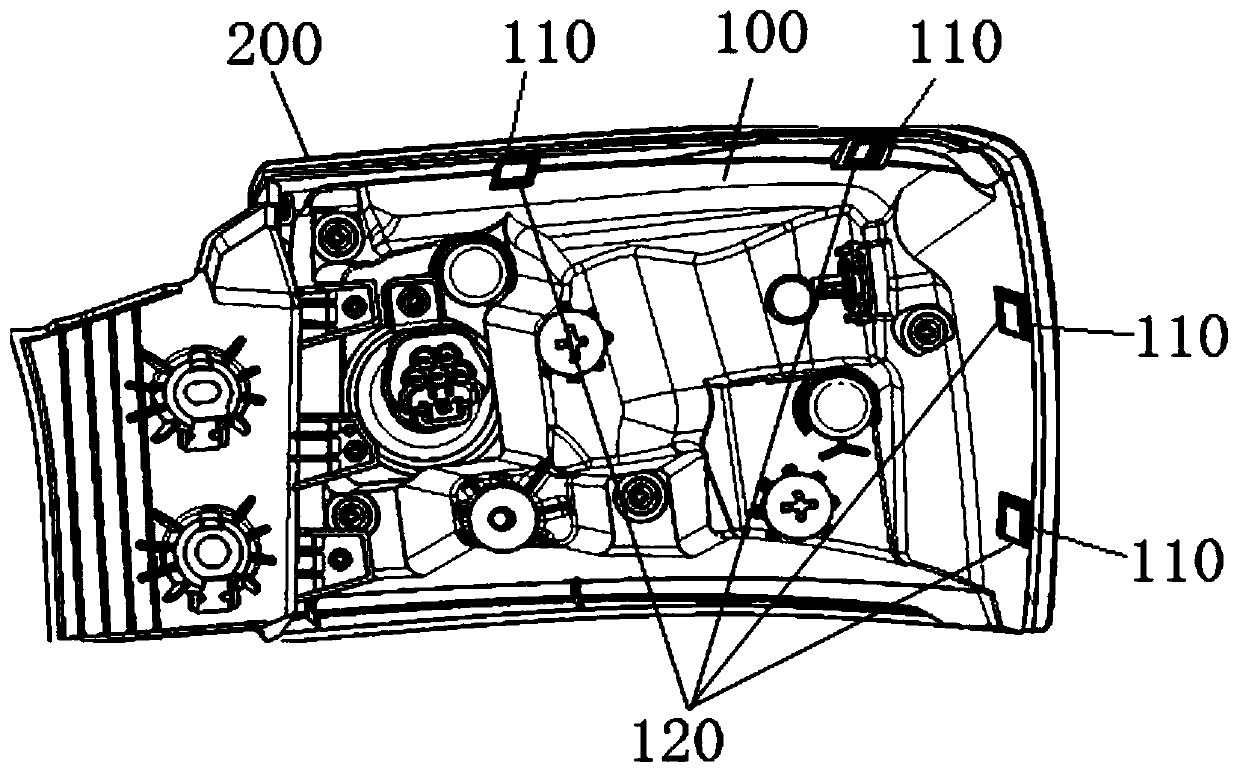

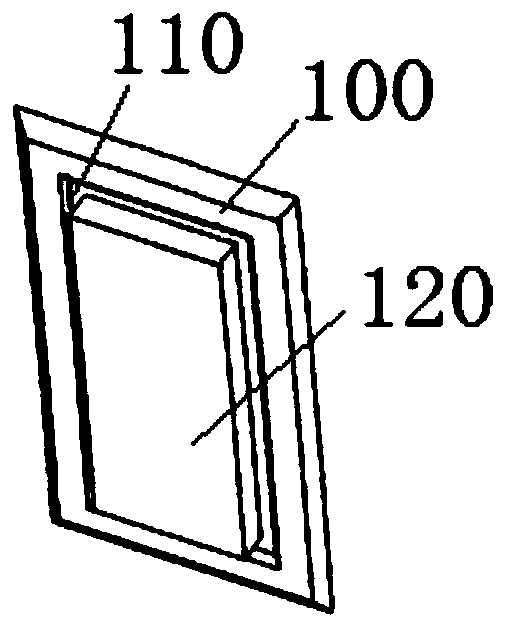

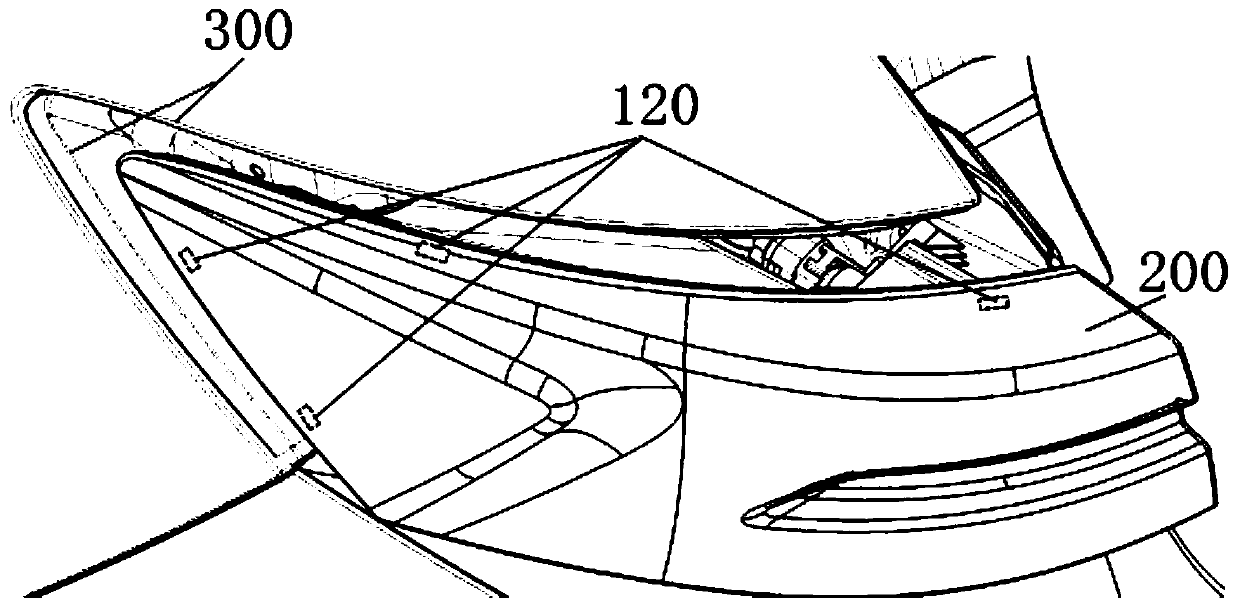

[0020] Such as figure 1 As shown, the vehicle taillight reinforcement structure for preventing vehicle body interference in the present invention includes a lamp housing 100 and a lamp shade 200. Groove 110, the groove surface of the positioning groove 110 is parallel to the installation surface of the lamp housing 100, the groove surface of the positioning groove 110 fits the bottom surface of the compressible boss 120, and the top surface of the compressible boss 120 is parallel to the positioning groove 110, the thickness of the compressible boss 120 after compression is the minimum gap between the lampshade 200 and the side panel 300 of the vehicle body. Therefore, the purpose of the compressible boss 120 designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com