Chamfering device for floor packaging boxes

A chamfering device and packaging box technology, applied in the direction of packaging, etc., can solve the problems of high work intensity of employees, affecting the utilization rate of packaging line equipment, low efficiency, etc., and achieve the effect of simple and convenient adjustment, convenient and fast adjustment, and good integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

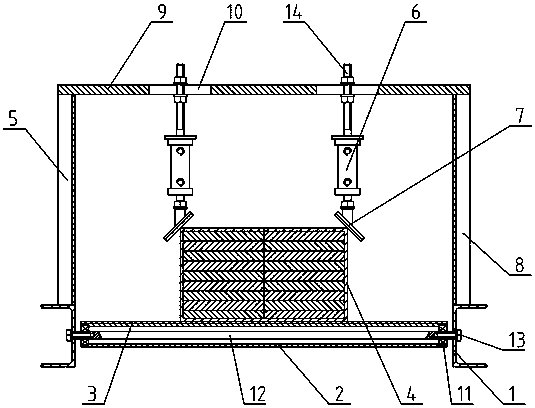

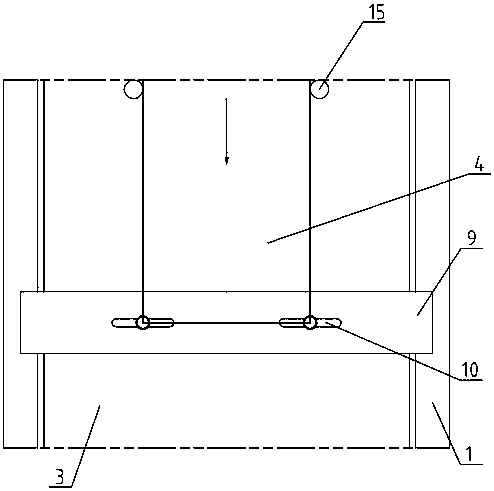

[0018] Such as figure 1 with figure 2 Shown: a chamfering device for floor packaging boxes, including two parallel brackets 1, a number of rollers 2 are arranged between the brackets 1, and a conveyor belt 3 is arranged on the rollers 2, and the conveyor belt 3 is used for Conveying the floor packing box 4, a door-shaped frame 5 is installed on the support 1, two cylinders 6 are installed on the door-shaped frame 5, and a chamfering block 7 is installed on the bottom of the cylinder 6. The chamfering blocks 7 are respectively in contact with the edges and corners on both sides of the top of the floor packing box 4 .

[0019] The gantry frame 5 includes a column 8 and a beam 9 , and the beam 9 is provided with two elongated holes 10 , and the cylinder 6 is installed under the beam 9 through the elongated holes 10 .

[0020] The bottom of the chamfering block 7 is provided with a polyurethane pad. The support 1 is a channel steel, and the drum 2 is equipped with a central sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com