Waste conveying device with vertical direction conveying function

A vertical direction, transportation device technology, applied in the directions of transportation and packaging, packaging, conveyor objects, etc., can solve the problems of single function, easy congestion of conveyed objects, and complex functions of transportation devices with height difference, and achieve high efficiency. , the effect of increasing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

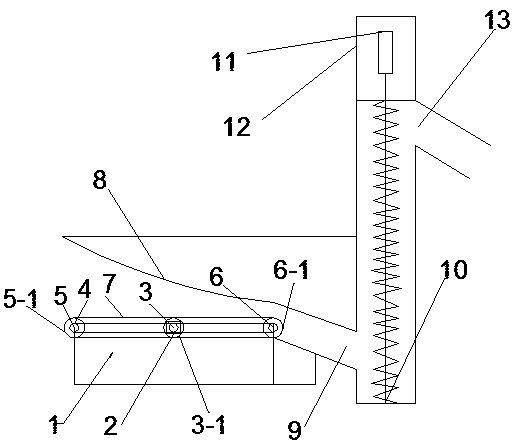

[0011] Such as figure 1 As shown, a garbage transport device with a vertical function includes a body 1, a drive motor 2, a first driving gear 3, a first gear reel 3-1, a conveyor belt 4, a second power gear 5, and a second gear Reel 5-1, third power gear 6, third gear reel 6-1, crawler belt 7, arc-shaped upper cover 8, delivery inlet 9, screw delivery rod 10, motor 11, motor housing 12, delivery outlet 13, The body 1 is an integral structure, which is divided into two functional parts: horizontal transportation and vertical transportation. The driving motor 2 is fixed on the horizontal part of the body 1. The first driving gear 3 is concentrically connected with the driving motor 2 and is set on the driving motor 2. Above, the driving motor drives the driving gear 3 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com