Textile cloth winding device capable of achieving switchable application

A technology of cloth rolling, left and right sides, applied in the field of textile rolling devices, can solve the problems that affect the rolling process, cannot meet the needs of mass production, and low efficiency, and achieve the effect of improving the production efficiency of enterprises and improving the work efficiency of cloth rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

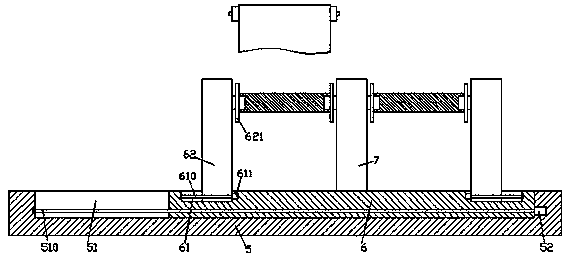

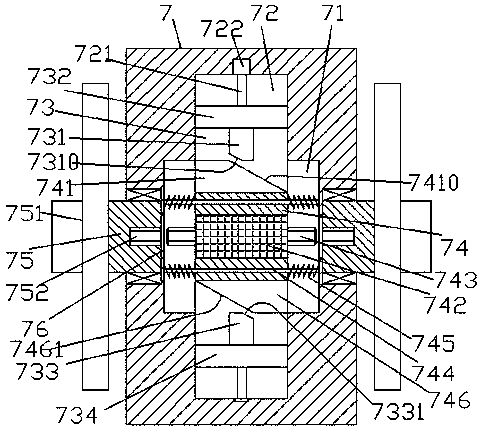

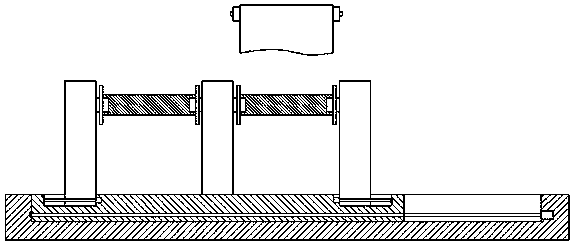

[0024] Such as Figure 1-Figure 5 As shown, a switchable textile cloth rolling device of the present invention includes a base 5 and a movable base 6 installed in the base 5, and the top end faces of the left and right sides of the movable base 6 are internally symmetrical. There are guide grooves 61, each of the guide grooves 61 is provided with a second threaded rod 610 extending from left to right, and the middle position of the top end surface of the moving bottom bracket 6 is fixed with a first support frame 7 extending upward, The left and right sides of the first support frame 7 are symmetrically provided with a second support frame 62 extending up and down. It is threadedly connected with the second threaded rod 610 in the guide groove 61 on the left and right sides, and the second support frame 62 on the left and right sides is connected to the opposite side of the top extension section of the first support frame 7 by rotation. The first locking member 621, the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com