Bobbin, winding machine, method for winding coil, and computer readable storage medium

A spool and axial technology, applied in the fields of winding such spools, winding machines, and software products, can solve problems such as acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

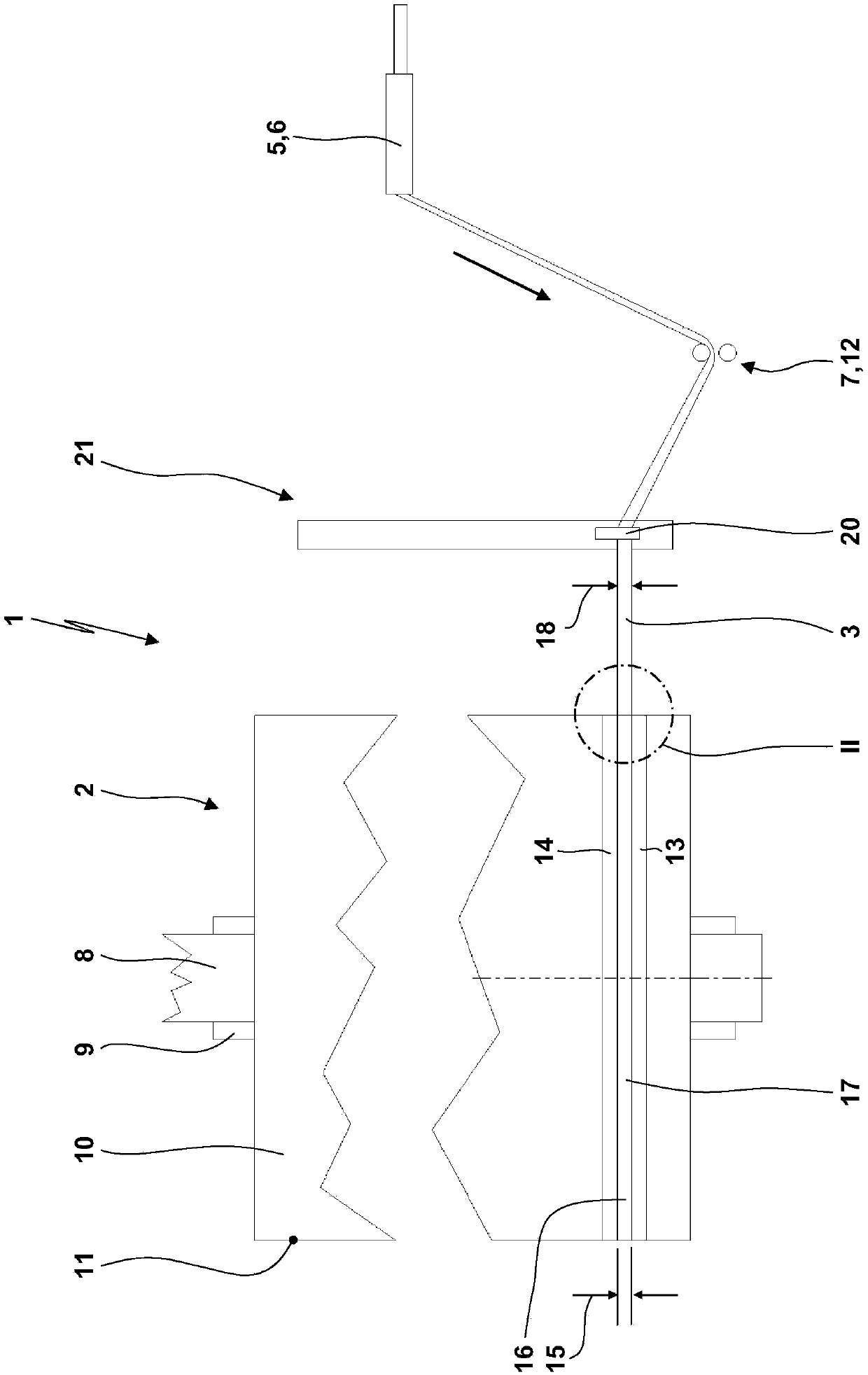

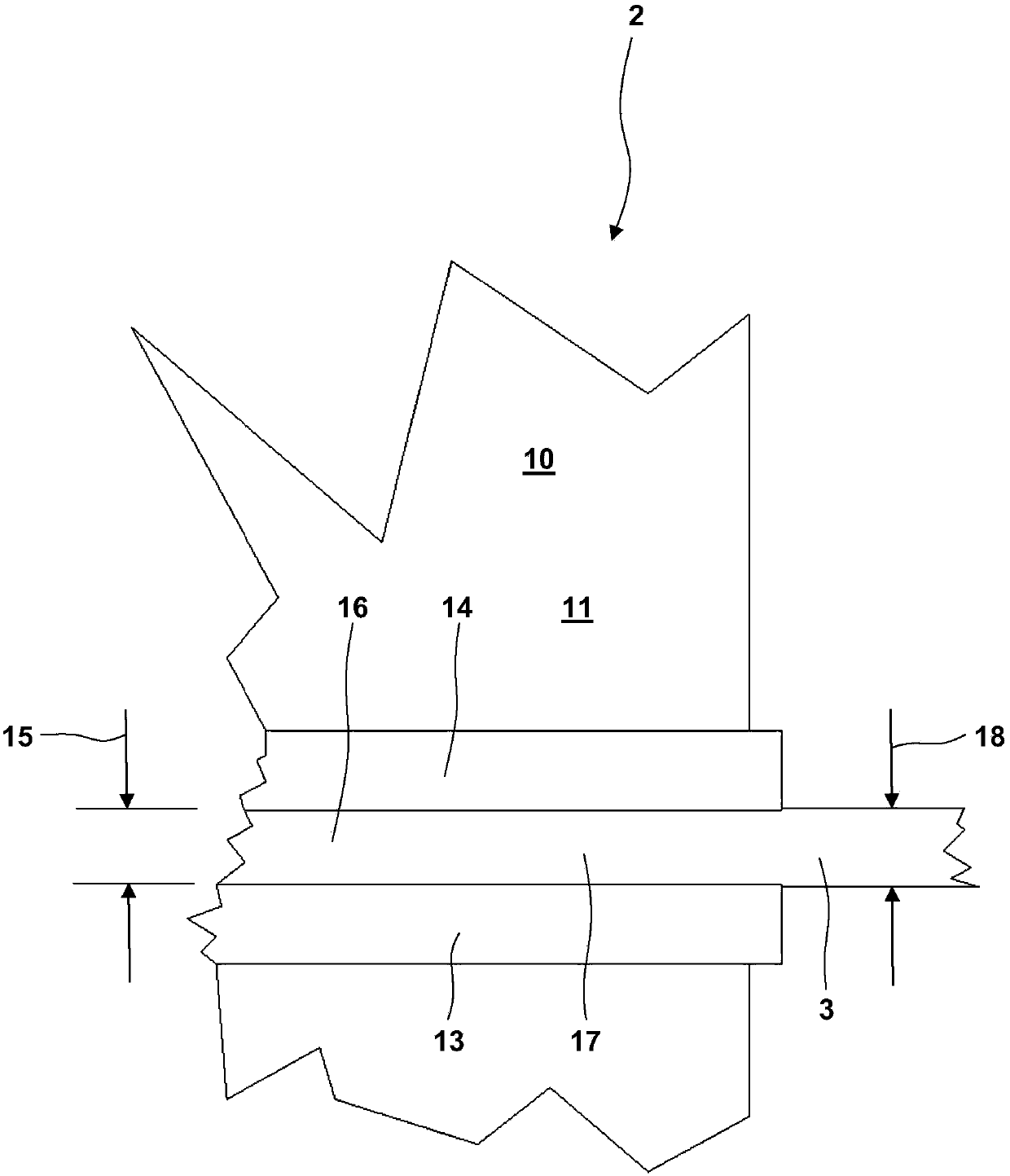

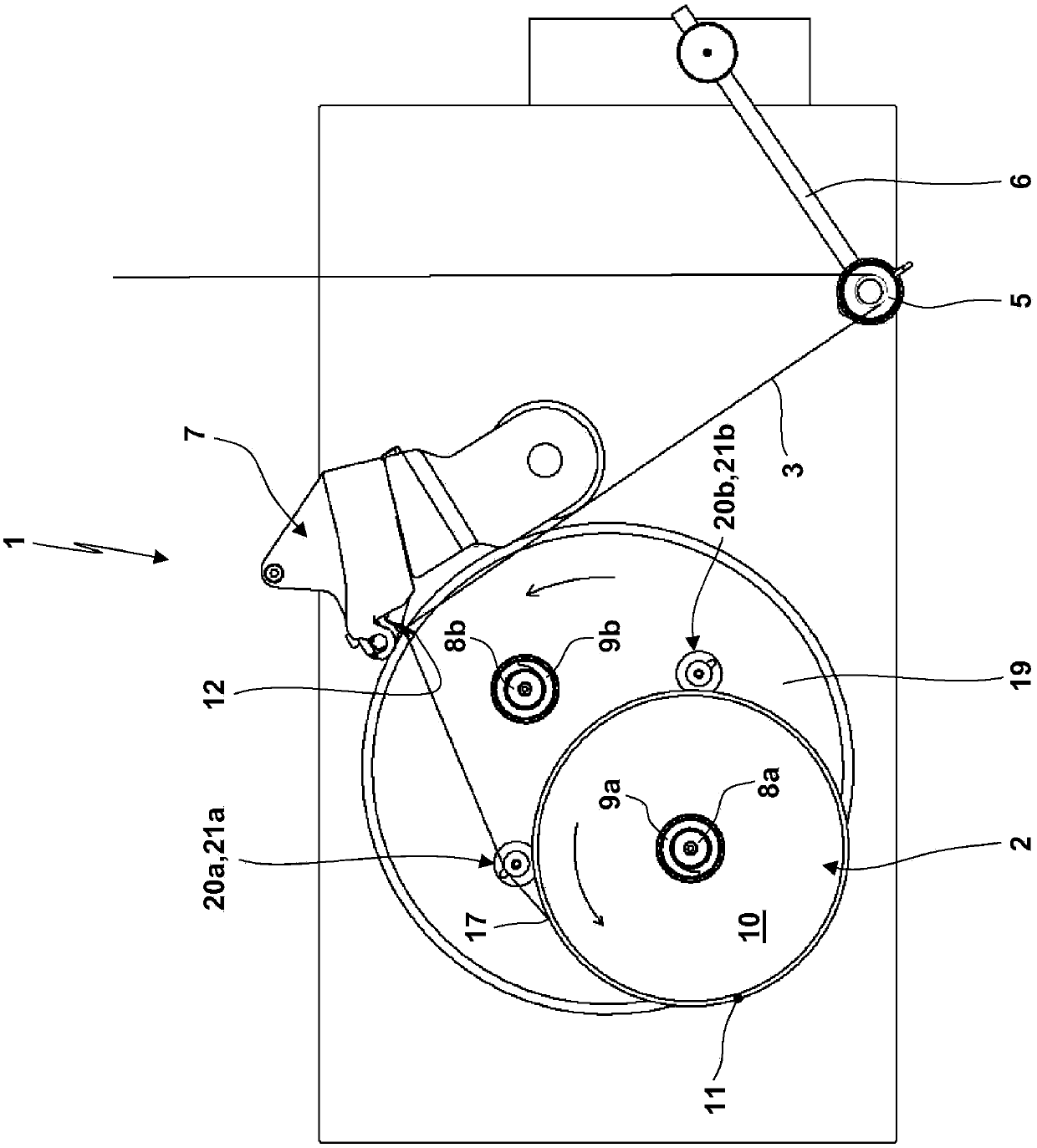

[0078] figure 1 The winder 1 is shown very schematically. This is also only the winding head of the winding device, wherein a plurality of bobbins can be wound in parallel on several winding heads by means of the winding device. For winding the bobbin 2, a winding 3 is provided discontinuously or preferably continuously, which is a tape-shaped winding. The winding 3 is conveyed to the bobbin 2 via means for influencing and maintaining the tension of the winding 3 , in particular deflection wheels 5 with associated adjusting arms 6 , and via a train unit 7 . The winding machine 1 here has a winding spindle 8 , onto which a winding sleeve 9 is pushed onto which a winding 10 of the winding 3 is wound. However, it is also possible to carry out the winding without using the winding sleeve 9 . The bobbin 2 is here formed by means of a winding sleeve 9 and a winding 10 . The drive of the bobbin 2 can be effected by the drive of the winding spindle 8 . It is also possible for the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap