Sealing device for red wine bottle upper cap

A wine bottle and cap sealing technology, applied in flange-type bottle caps and other directions, can solve the problems of high cost of high-precision robotic arms, high enterprise cost, broken wine bottles, etc., so as to avoid insufficient precision and realize automatic sealing. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

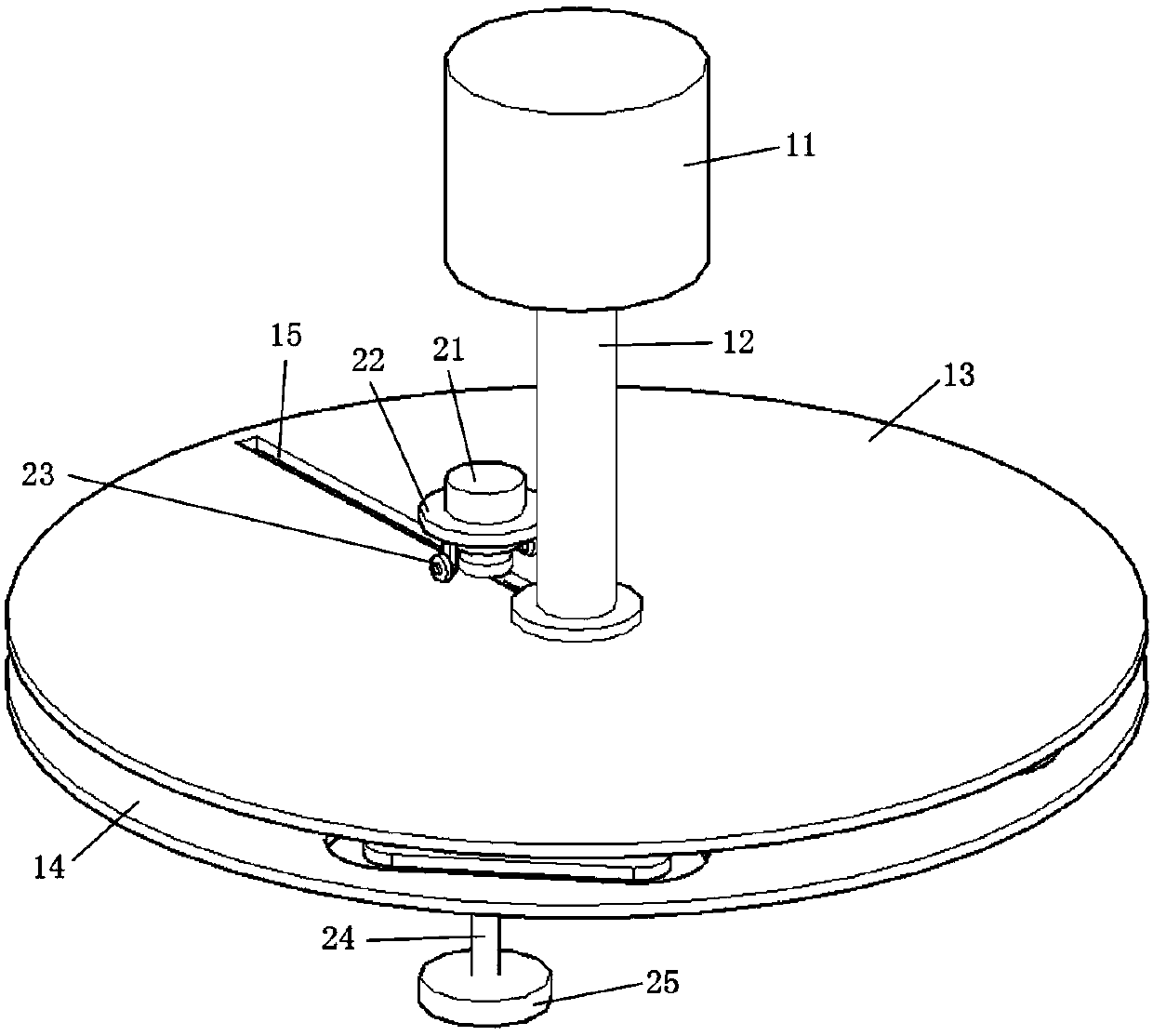

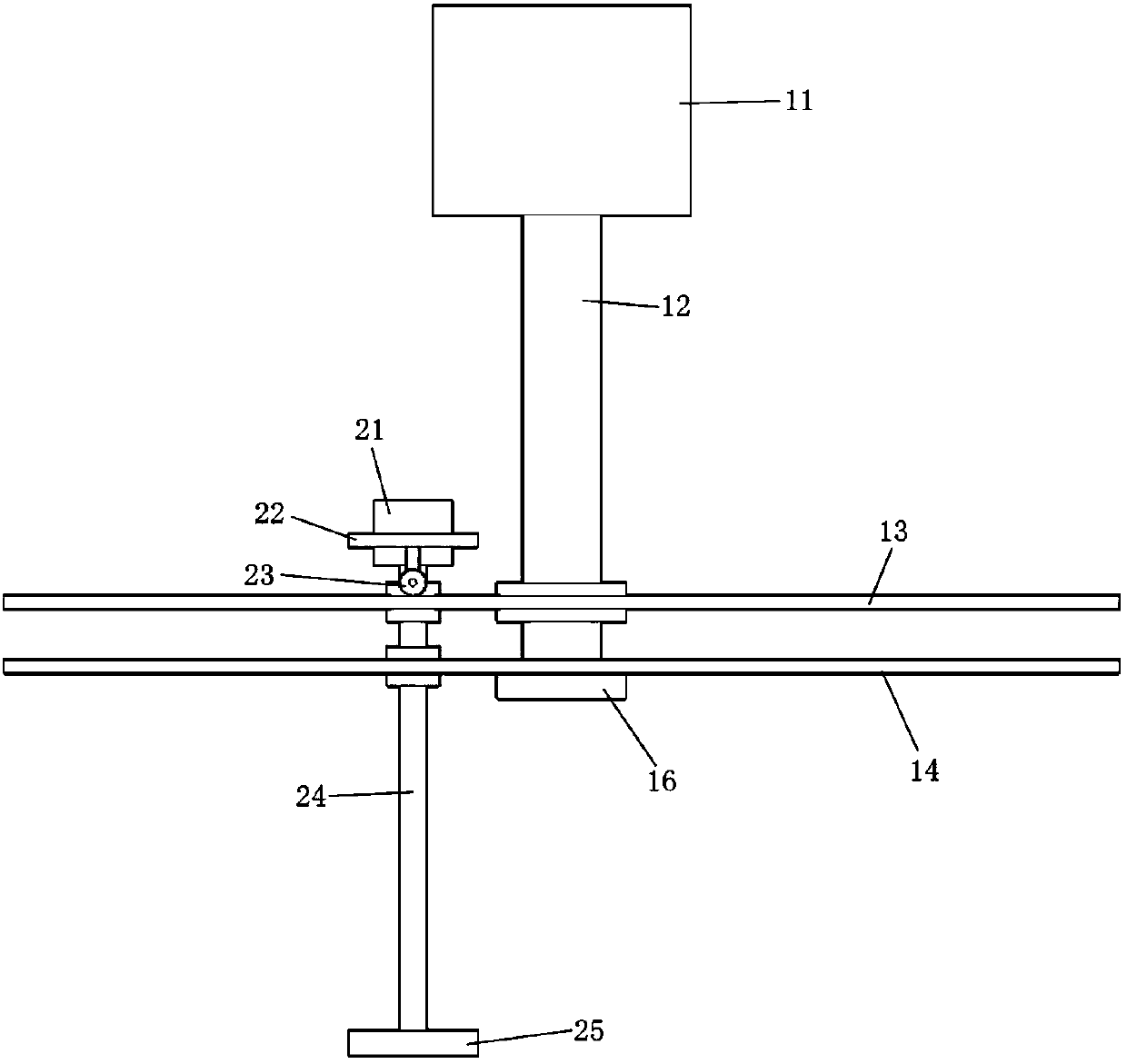

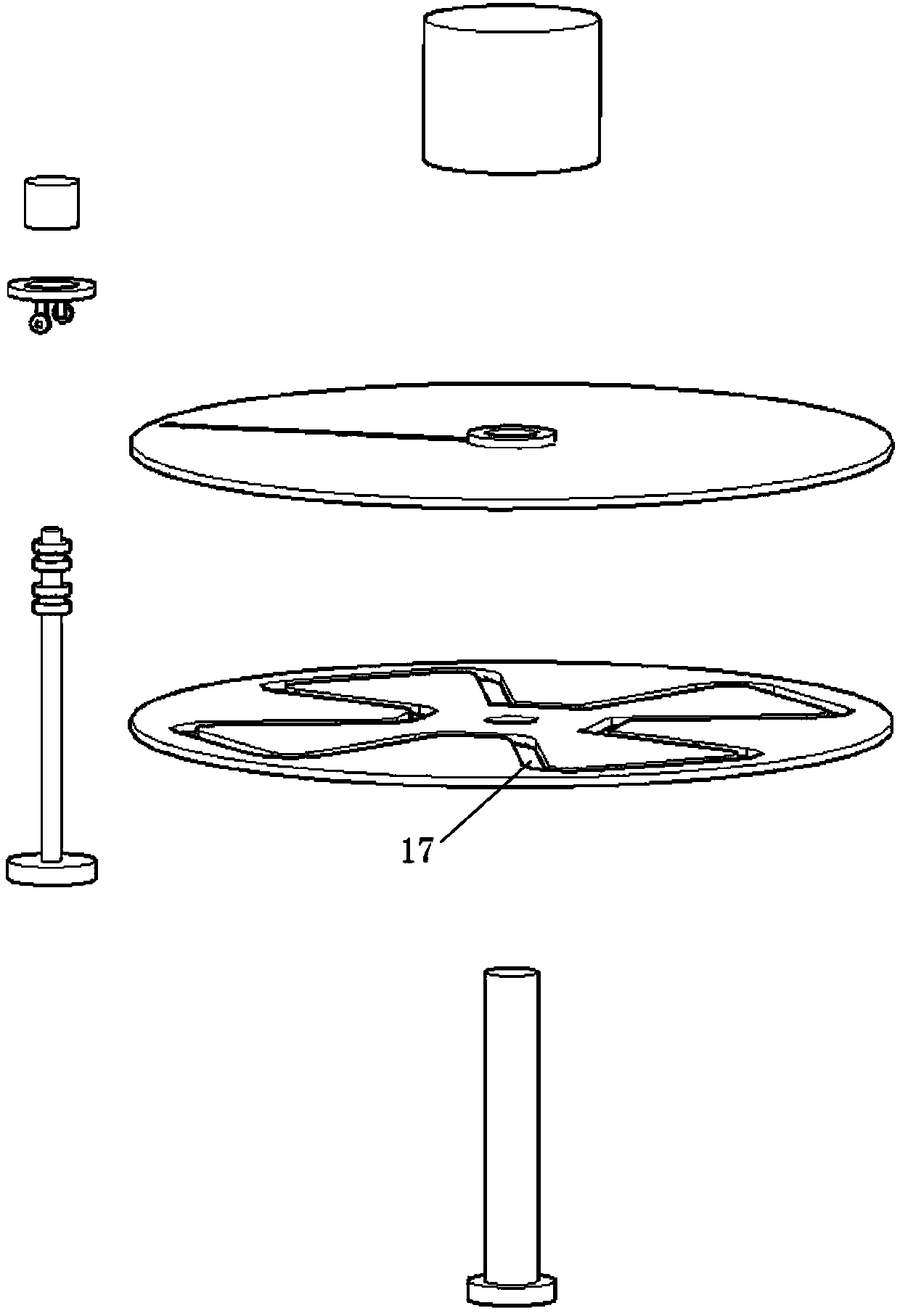

[0019] Such as Figure 1 to Figure 3 A sealing device for the upper cover of a red wine bottle is shown, including a position control motor 11, a position control shaft 12, a limit plate 13, a molding plate 14, a limit groove 15, a telescopic motor 21, a telescopic rod 24, and a sealing mechanism mounting seat 25 ; The position control motor 11 is driven by the top of the position control shaft 12 to rotate the position control shaft 12, the position control shaft 12 is vertically arranged, the middle part of the position control shaft 12 is equipped with a horizontal limit disc 13 and a molding disc 14, and the limit disc 13 is fixed On the position control shaft 12, the modeling disc 14 is self-fixed and can rotate relative to the position control shaft 12. The limit disc 13 is provided with at least one position limiting groove ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap