Industrial wastewater nanofiltration separation system

A technology for separation system and industrial sewage, which is applied in semi-permeable membrane separation, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of adjusting water output rate, affecting sewage treatment efficiency, and poor water flow through nanofiltration membranes. and other issues, to achieve the effect of improving the use effect, increasing the use width, and guaranteeing the water outlet efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

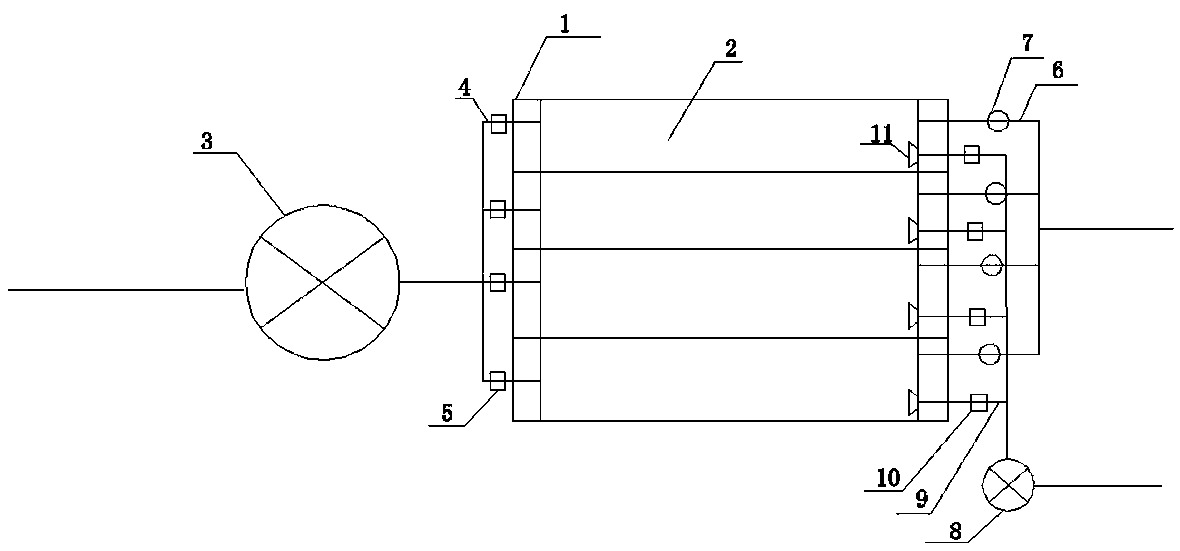

[0014] Such as figure 1 As shown, the present invention provides a nanofiltration separation system for industrial sewage, including a nanofiltration box 1 and an inlet pump 3. The nanofiltration box 1 is provided with four nanofiltration devices 2, and the nanofiltration devices 2 are respectively provided with The inlet pipe 4 and the outlet pipe 6, the inlet pipe 4 is connected to the inlet pump 3, the inlet pipe 4 is provided with an inlet valve 5, the outlet pipe 6 is provided with a flow meter 7, the nanofiltration device 2 There is also a cleaning pipe 9 connected to the cleaning pump 8, the cleaning pipe 9 is provided with a cleaning valve 10, and the inner wall of the nanofiltration device 2 is provided with a shower connected to the cleaning pipe 9 Head 11.

Embodiment 2

[0016] According to the process requirements of sewage treatment, 3 nanofiltration devices 2 are required to be put into use at the same time. Open 3 of the 4 water inlet valves 5, and the water inlet pump 3 pumps industrial wastewater into these 3 nanofiltration devices 2 for nanofiltration. For processing, the staff observes the corresponding flow meters 7 on the water outlet pipes 6 of the three nanofiltration devices 2. Once it is found that the water output rate of one of the flow meters 7 is significantly lower than that of the other two, it is determined that the nanofiltration device 2 When a blockage occurs, the staff closes the water inlet valve 5 of the nanofiltration device 2 and opens its cleaning valve 10 at the same time. The cleaning pump 8 flushes the clean water through the spray head 11 to the nanofiltration device 2 and opens the other An unused water inlet valve 5 of the nanofiltration device 2 is put into use, so that in the process of cleaning the clogged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com