Method for installing and stress monitoring of steel bar cage in concrete cast-in-place pile

A technology of stress monitoring and steel cage, which is applied in the test of basic structure, construction, basic structure engineering, etc. It can solve the problems that it is difficult to ensure that the wire is fixed at the predetermined safe position, the settlement of the steel cage is large, and the monitoring effect is affected, so as to achieve safety. Efficient wire fixing quality, good monitoring data and effect, convenient and fast construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

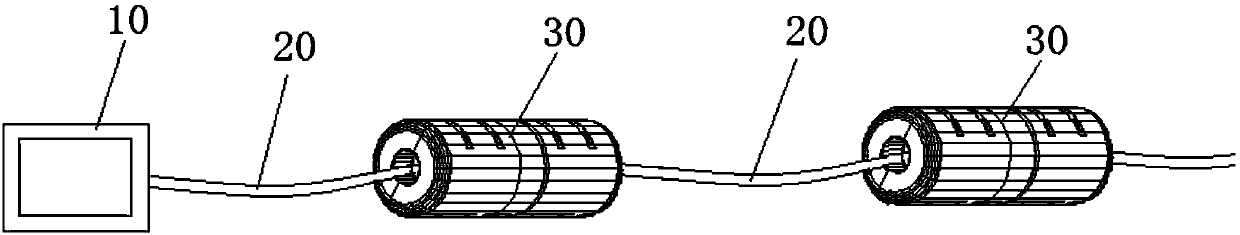

[0042] Such as figure 1 As shown, a steel bar strain gauge for multi-section steel cage installation includes a strain gauge body 10 and a strain gauge lead 20 .

[0043] The stress gauge body is fixedly arranged on the steel bar to be tested in the multi-section steel cage, one end of the strain gauge wire is fixedly connected with the strain gauge body, and the other end of the strain gauge wire is connected with the stress monitoring device.

[0044] The strain gauge lead includes a lead segment and a lead joint 30; the number of the lead segment is several, and two adjacent lead segments are connected through a lead joint.

[0045] Each wire segment is bound on the corresponding section of the steel cage, and the wire joint is arranged at the junction of two adjacent sections of the steel cage.

[0046] Conductive wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com