Axial flow pump with adjustable water drainage angle

A technology of axial flow pumps and angles, which is applied to pumps, components of pumping devices for elastic fluids, pump devices, etc., can solve problems that affect work stability and poor water delivery, and achieve stable and guaranteed water delivery The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

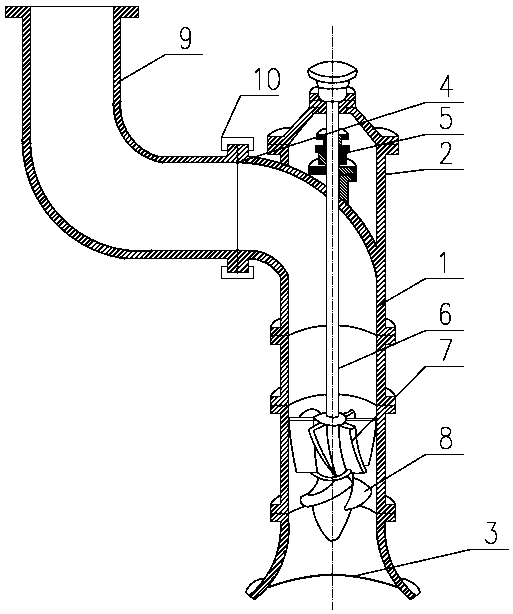

[0013] Such as figure 1 As shown: the axial flow pump with adjustable outlet angle in this embodiment includes a first pump casing 1 and a second pump casing 2 connected to the first pump casing, and the bottom of the first pump casing is provided with a water inlet bell mouth 3 , the upper part is provided with a water outlet elbow 4, the second pump casing is arranged above the first pump casing, a power device 5 is arranged inside the second pump casing, and the power device is connected to the drive shaft 6, The drive shaft passes through the first pump casing and extends downward along the axial center of the first pump casing. The lower part of the drive shaft is provided with guide vanes 7 and impellers 8, and the outlet elbow passes through The flange is connected to the middle turning elbow 9, and the middle turning elbow adopts a 90° rounded elbow, and the flange connection between the middle turning elbow and the outlet elbow is provided with a sealing ring. The be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com