Fault detecting and handling method of air conditioner and subcooling pipe set thereof

A technology of fault detection and processing method, applied in the field of air conditioners, can solve problems such as affecting the performance of air conditioners, low frequency of occurrence, damage to one-way valves, etc., achieving the effect of simple and convenient detection process and preventing one-way valve failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

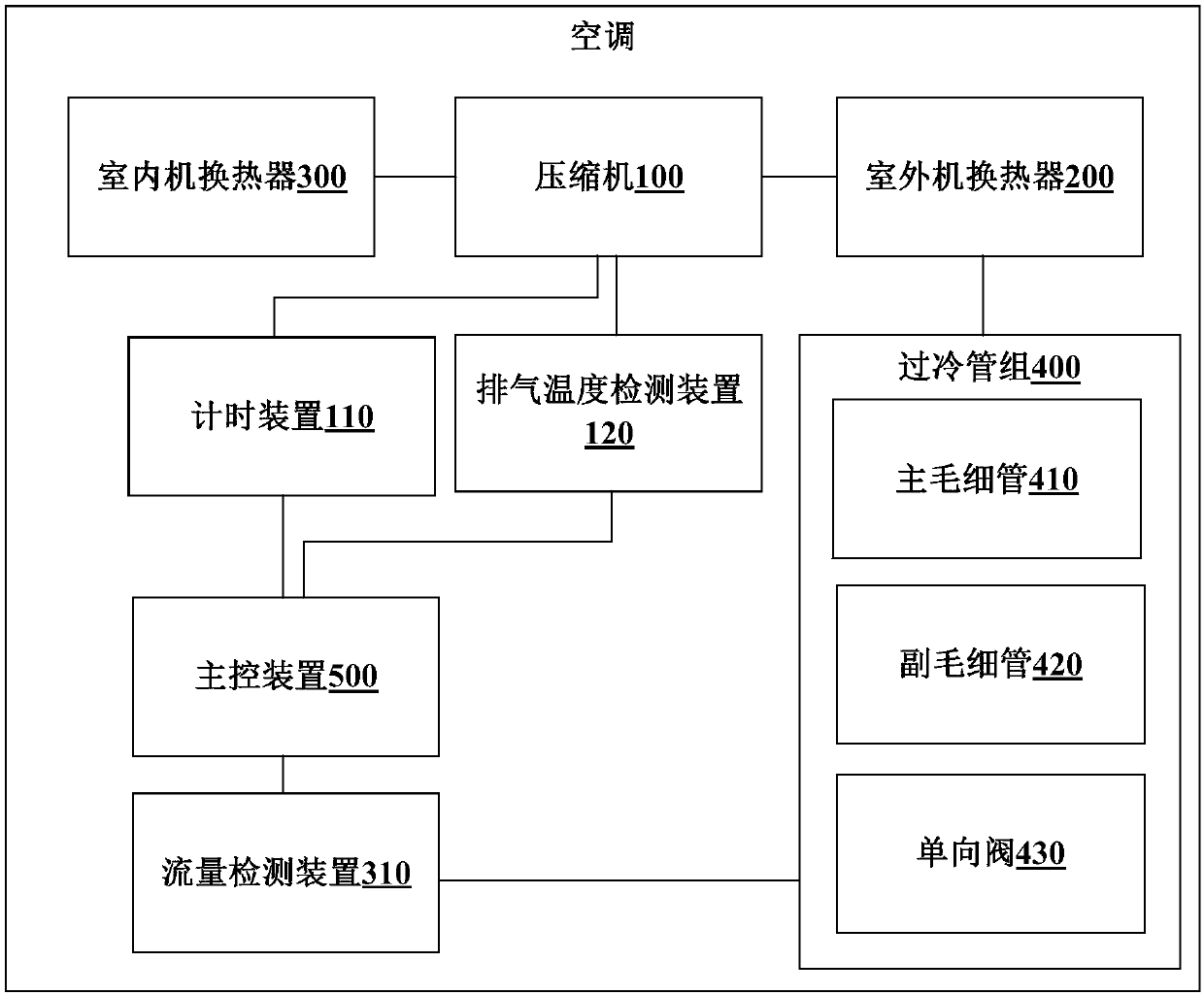

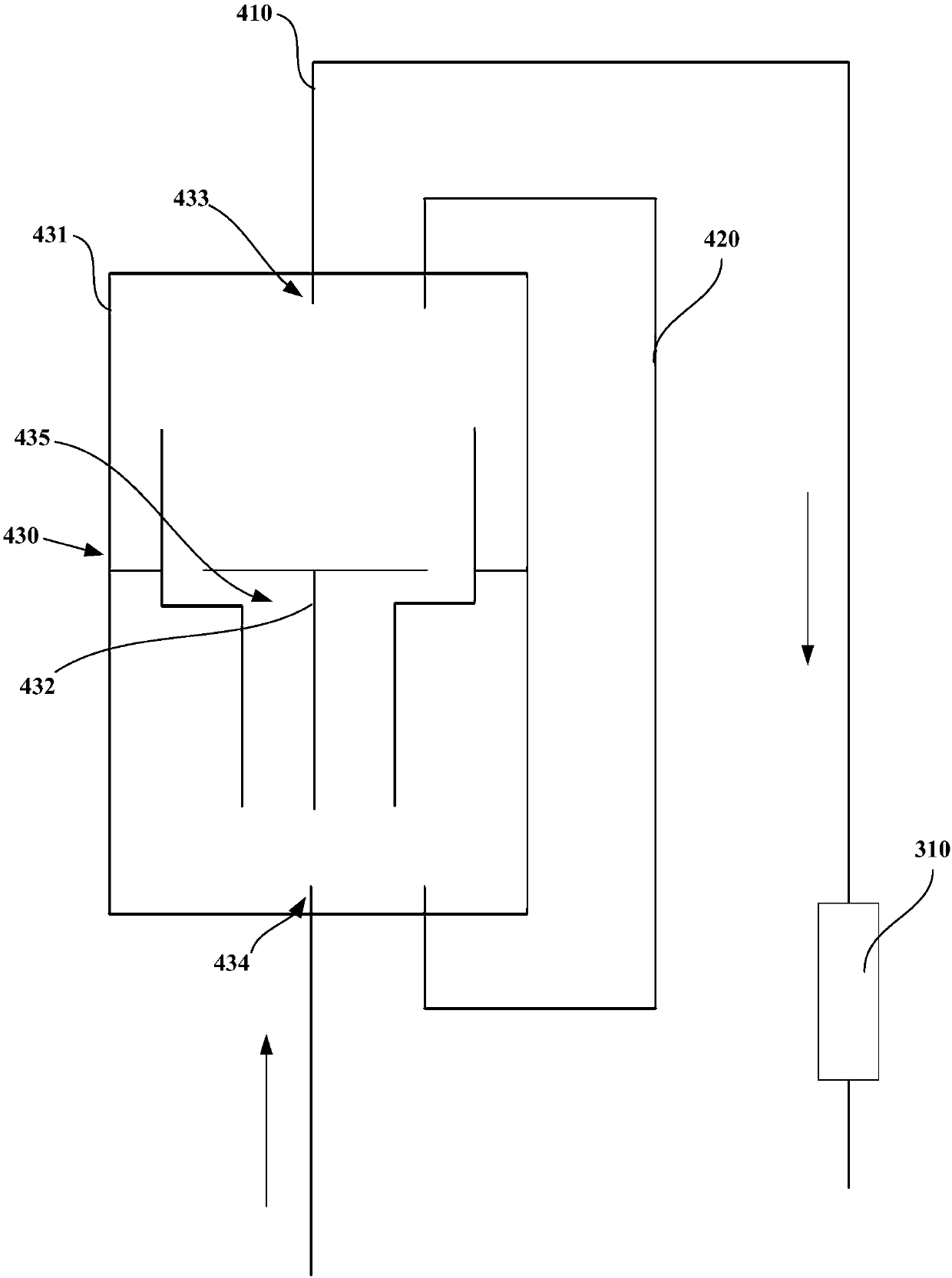

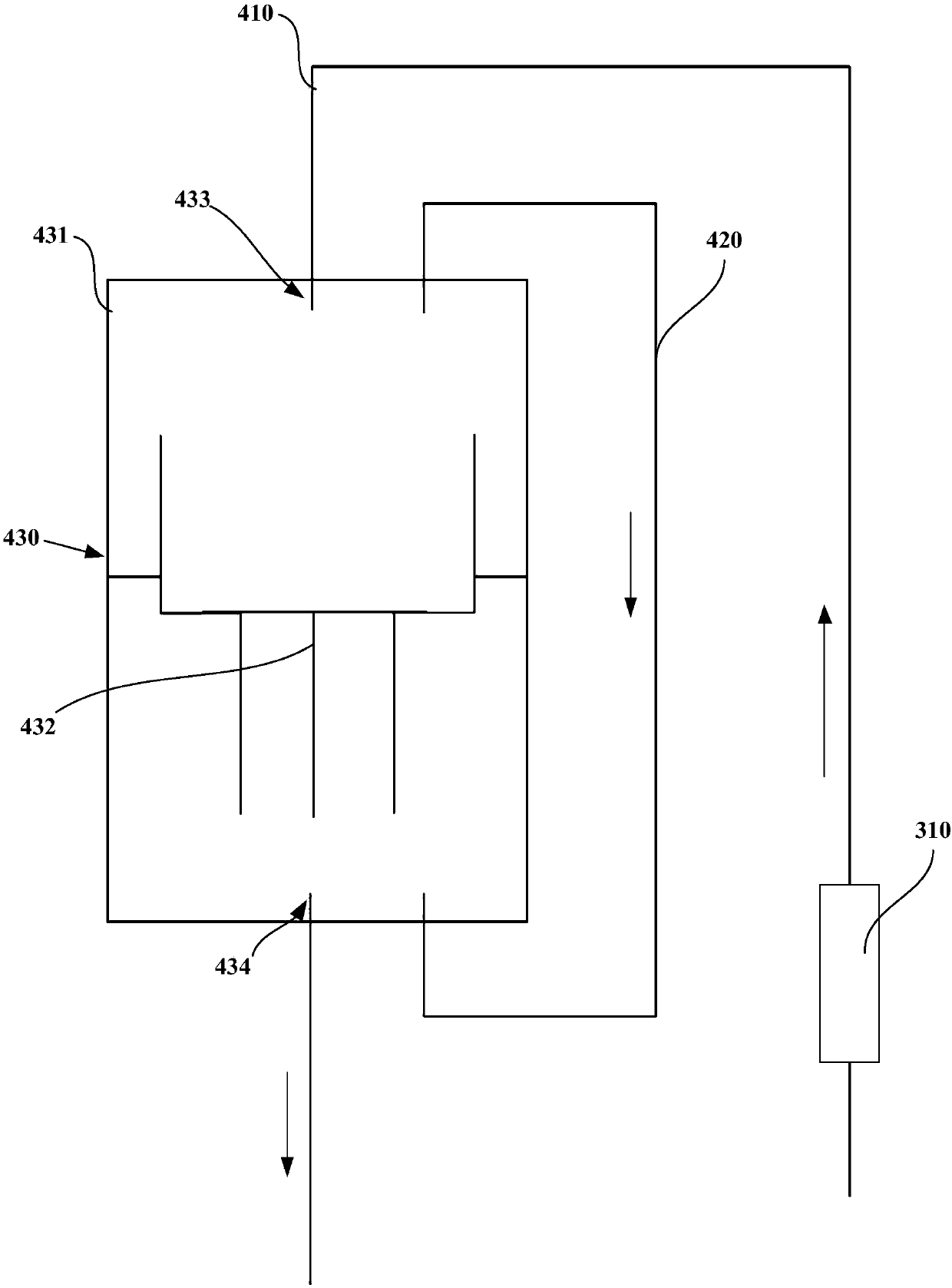

[0026] The embodiment of the present invention firstly provides an air conditioner, including: a refrigerant circulation system formed by sequentially connecting a compressor 100 , an outdoor unit heat exchanger 200 and an indoor unit heat exchanger 300 . The supercooling tube group 400 is arranged downstream of the refrigerant flow path of the outdoor unit heat exchanger 200. The above-mentioned "downstream" refers to the refrigerant that is directly or indirectly connected to the outdoor unit heat exchanger 200 by the supercooling tube group 400 under the normal cooling state of the air conditioner. exit. In the cooling state, the refrigerant flows sequentially through the compressor 100, the outdoor unit heat exchanger 200, the subcooling tube group 400 and the indoor unit heat exchanger 300, and in the heating state, the refrigerant starts to circulate in the opposite direction from the compressor 100 . The subcooling tube group 400 includes: a main capillary 410 , a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com