Machine for clearing crust in intelligent cement kiln

A cement kiln and cleaning machine technology, applied in the direction of descaling devices, furnaces, lighting and heating equipment, etc., can solve the problems of affecting heat transfer in the kiln, personal injury of workers, work hazards, etc., and achieve high efficiency and easy broken cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

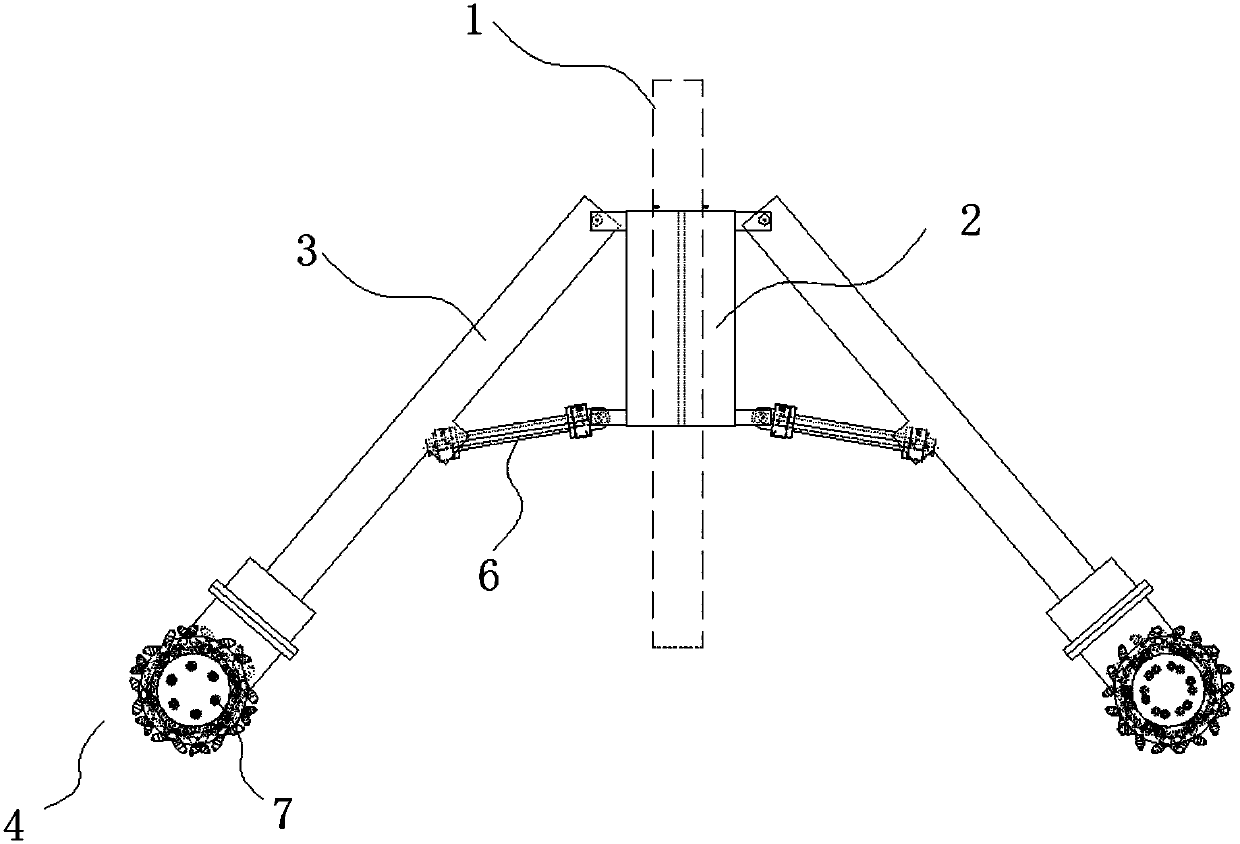

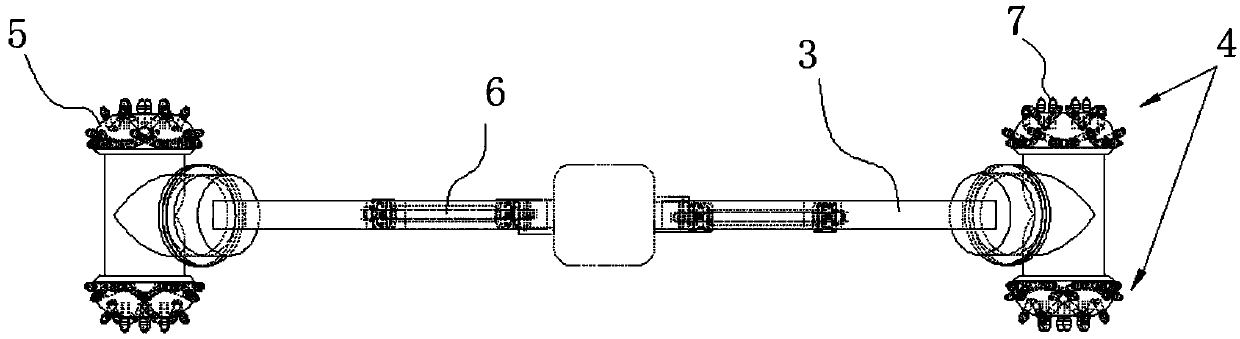

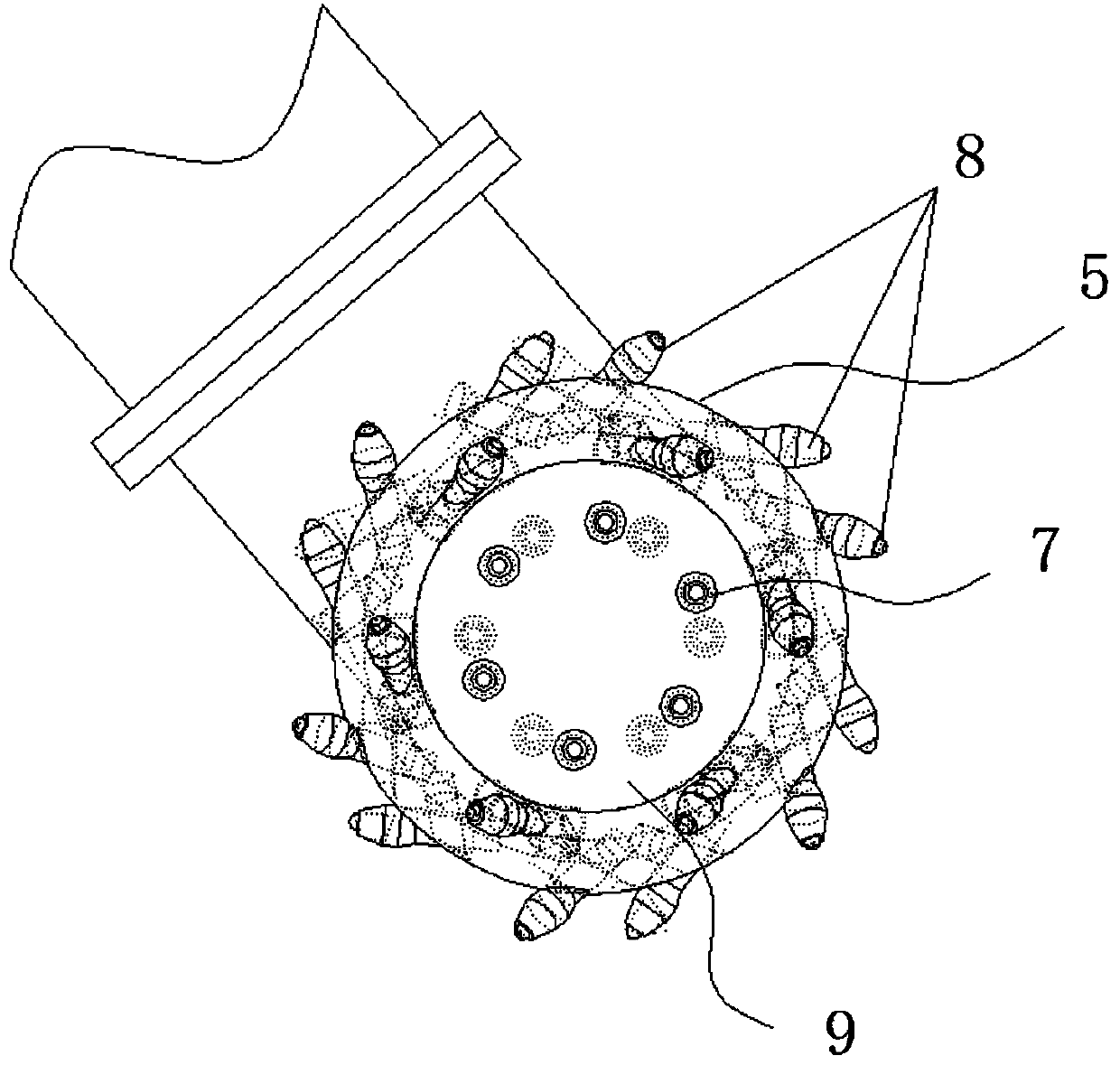

[0018] Such as Figure 1 to Figure 3 As shown, the intelligent cement kiln internal crust cleaning machine includes a rotating sleeve 2 that is rotatably installed on the movable rod 1. A supporting arm 3 is installed on the outer peripheral surface of the rotating sleeve 2, and a rotating sleeve is installed on the outer end of the supporting arm 3. Cleaning head 4; also includes the rotating driving device that drives described rotating sleeve 2 to rotate, and driving sleeve rotates under the drive of rotating driving device, and rotating driving device can adopt gear transmission etc., drives the cleaning head driving device that described rotating cleaning head 4 rotates , the rotating cleaning head rotates under the drive of the cleaning head driving device, and the cleaning head driving device can adopt a chain drive or the like.

[0019] The supporting arm 3 is hinged outside the rotating sleeve 2 , and the rotating sleeve 2 is also provided with an adjusting device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com