Abrasion detection method and system for contact network

A detection method and catenary technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of low detection accuracy, and achieve the effect of overcoming the loss of image information and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A catenary wear detection method, comprising the following steps:

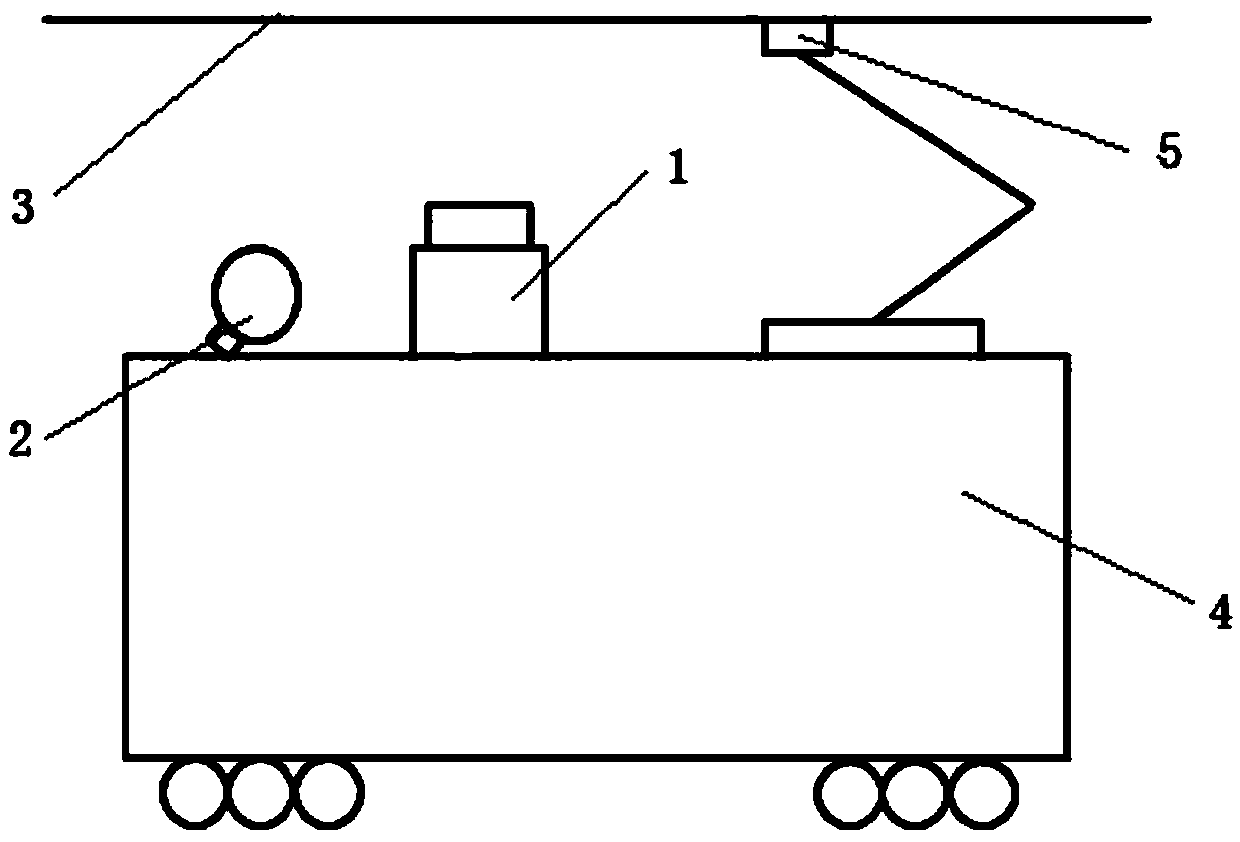

[0030] Place a line array camera 1 and light supplement equipment 2 on the roof of the electric locomotive 4, the scan line of the line array camera is perpendicular to the arrangement direction of the contact line 3, and the irradiation area of the supplement light equipment is the scan line area of the line array camera;

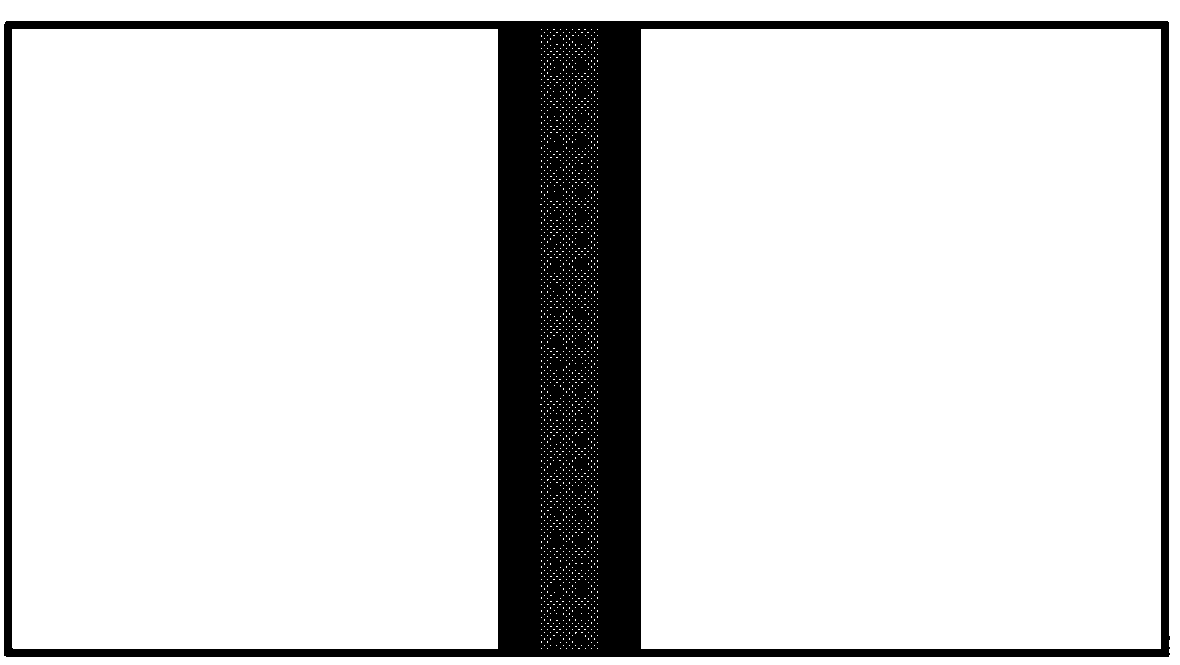

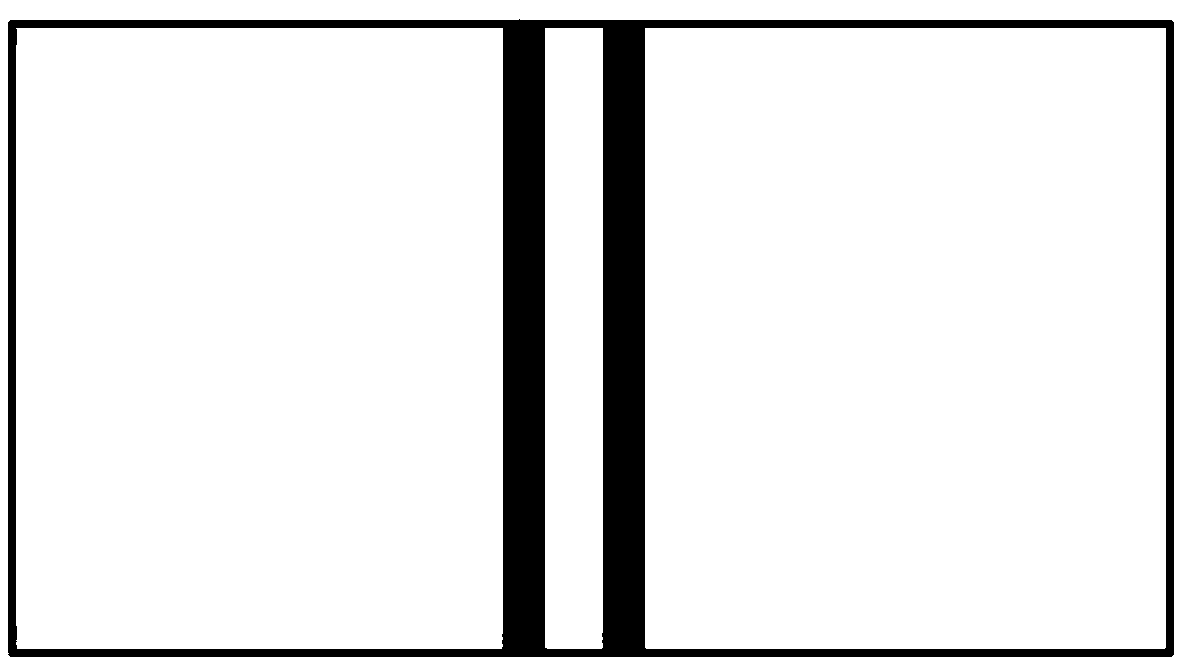

[0031] When the electric locomotive is running, control the on and off of the supplementary light equipment. When the supplementary light equipment is off, the line array camera obtains the contact surface image a of the contact line and the pantograph 5; Bow 5 contacts surface image b;

[0032] Perform differential calculation on image a and image b to obtain the image of the wear area of the contact line;

[0033] The width of the worn part of the contact line 3 is calculated from the image.

[0034] The supplementary light device 2 adopts an LED strobe supplementary light...

Embodiment 2

[0038] Based on the method in Embodiment 1, this embodiment discloses a system for implementing the above method. Such as figure 1 The system shown includes a line array camera 1, supplementary light equipment 2, and a wear calculation device. The line array camera 1 is used to obtain an image perpendicular to the direction in which the contact line is arranged, that is, its scanning line is perpendicular to the contact line; the supplementary light equipment 2 Carry out supplementary light to the image acquisition area of the line array camera, and its supplementary light area is also perpendicular to the contact line; Line array camera 1, supplementary light device 2 obtain image a, image b according to the method of embodiment 1; a. Image b is differentially calculated to obtain an image of the worn area of the contact line, and the width of the worn area of the contact line is calculated based on the image.

[0039] The supplementary light equipment preferably adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com