Boost converter-based anti-input voltage and anti-load fluctuation control system

A converter control and input voltage technology, applied in electrical components, output power conversion devices, etc., can solve the problems of complex control and high requirements, it is not suitable for occasions, the measures are complex and difficult to implement, etc., and the model is simple and easy. effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

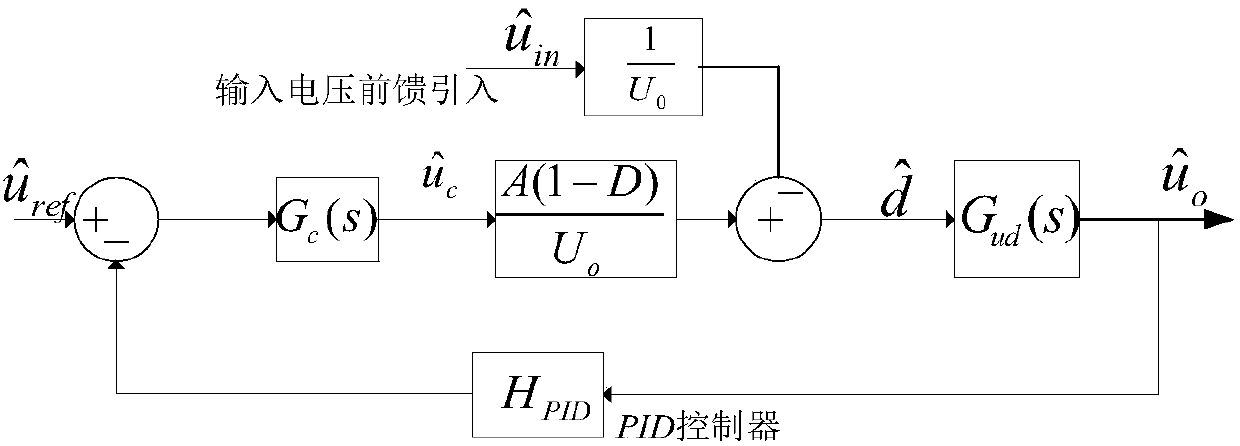

[0047] According to a specific embodiment of the present invention, a control system based on a boost converter against input voltage and load fluctuation is disclosed:

[0048] Including input voltage feedforward system, boost converter control system, and verification system, in which the input voltage feedforward system is used to add feedback to the boost converter control system before the input voltage, and the verification system collects and verifies the circuit parameters after adding feedback ;

[0049] The modeling process of the input voltage feedforward system is as follows:

[0050] When the boost converter adopts the trailing edge PWM pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com