Anti-explosion electric heating tube

An electric heating tube and electric heating tube technology, which is applied to the ohmic resistance heating parts, the shape of the heating element, the dissolution and other directions, can solve the problems of the electric heating tube element having a large amount of heat accumulation, the electric heating tube element bursting, and the heating medium being heated too fast, etc. To achieve the effect of promoting heating, avoiding pipe bursting, and alleviating heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

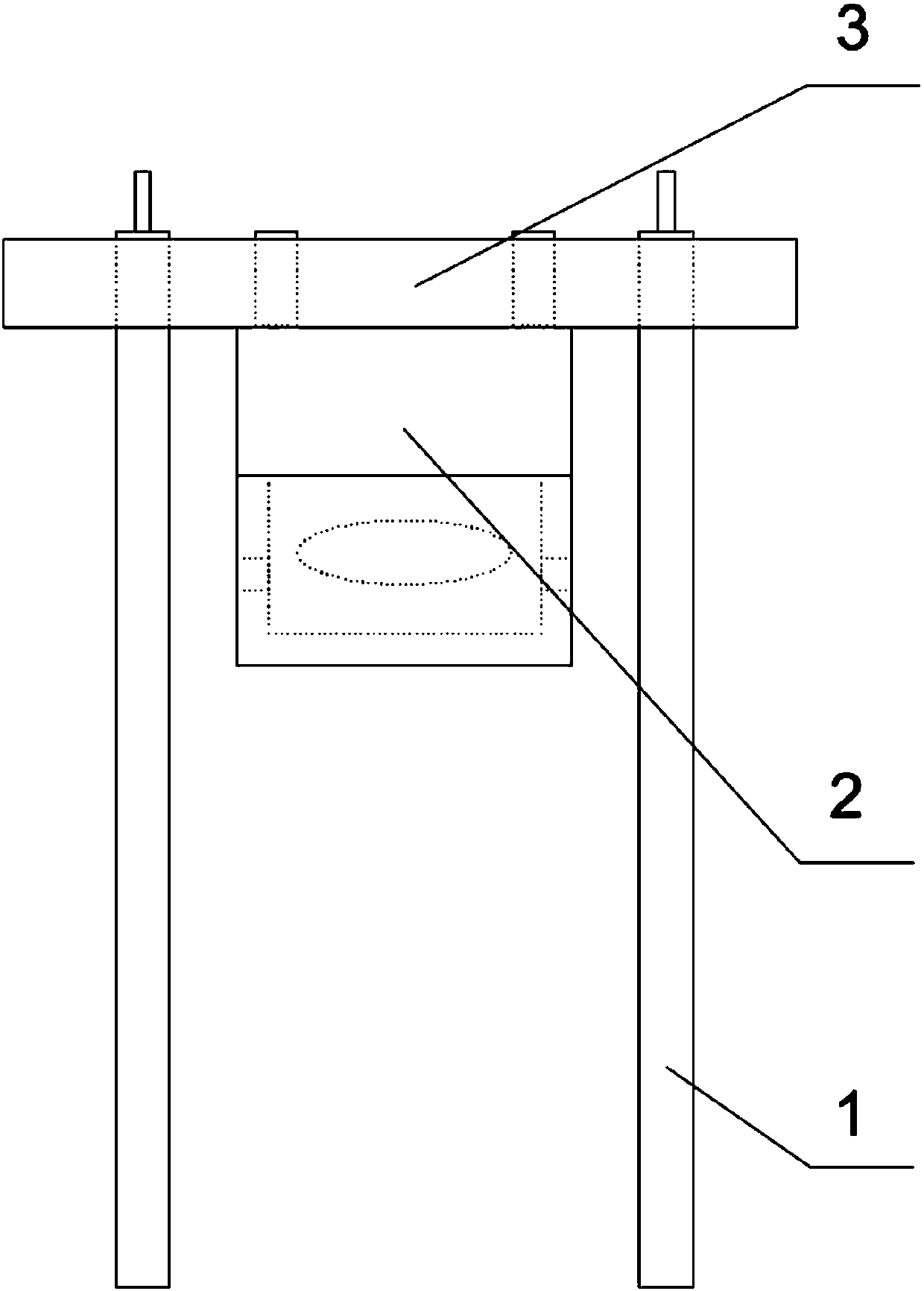

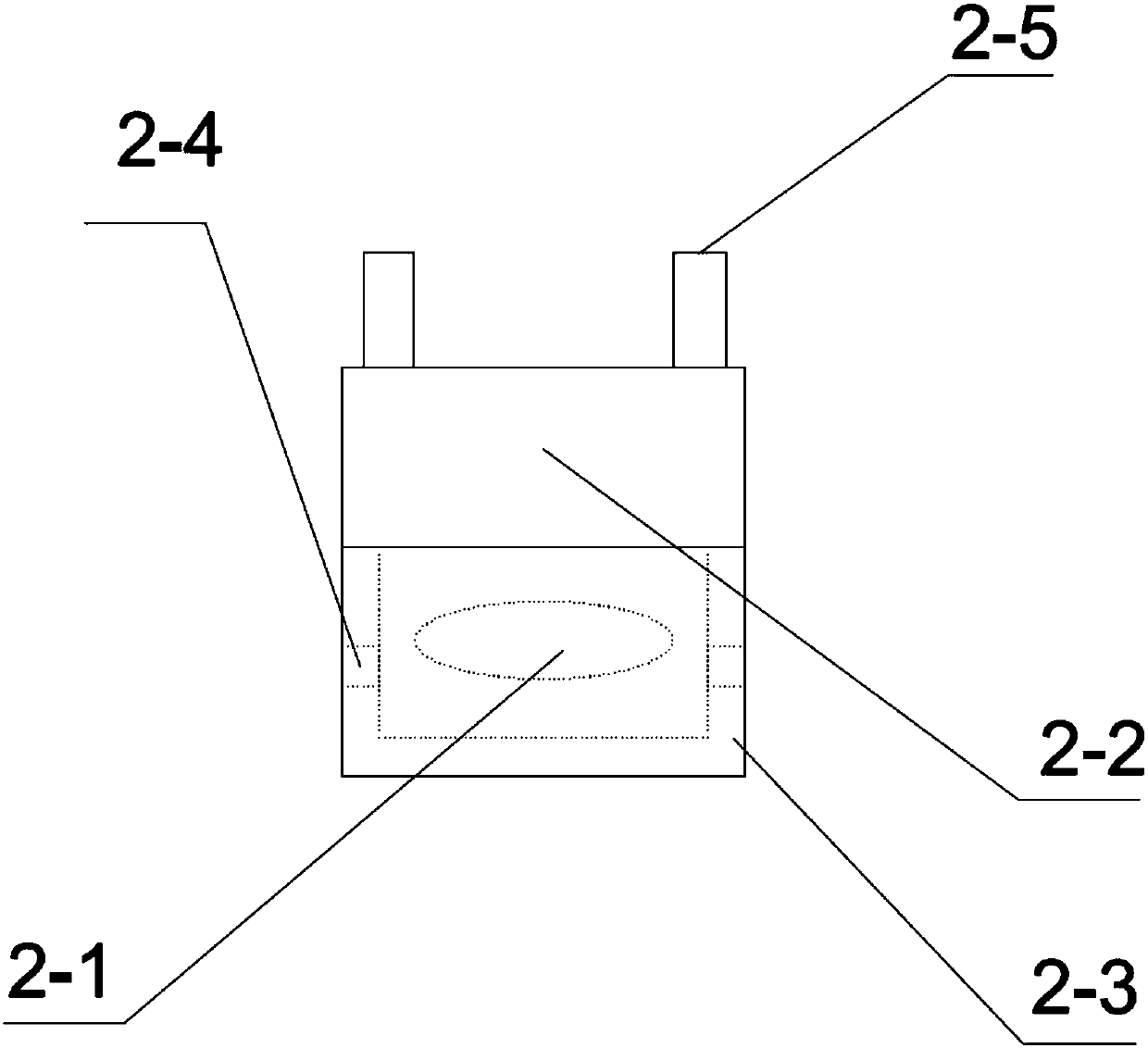

[0016] An explosion-proof electric heating tube, including an electric heating tube element 1, a miniature magnetic stirring device 2, and a flange 3; the miniature magnetic stirring device 2 includes a magnetic stirrer 2-1, a magnetic base 2-2, and a stirrer position limiting cover 2- 3. Medium inlet and outlet holes 2-4, stirring device fixing parts 2-5; electric heating pipe element 1 and miniature magnetic stirring device 2 are located on the same side of flange 3, miniature magnetic stirring device 2 is located in the center of flange 3, and electric heating pipe element 1 Surrounding the outside of the miniature magnetic stirring device 2; one end of the electric heating tube element 1 is welded on the flange 3; the miniature magnetic stirring device 2 is welded on the flange 3 through the stirring device fixing part 2-5; the magnetic base 2-2 and the stirring bar The position limiting cover 2-3 is connected; the magnetic stirrer 2-1 is located in the chamber formed by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com