Pipe reeling machine tool and pipe reeling method

A technology of coiling and machine tools, applied in the field of coiling machine tools and coiling, can solve the problems of low production efficiency, uncontrollable diameter range of coiled tubes, poor applicability, etc., and achieves reasonable structure, simple and easy-to-operate method of coiling, and applicability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make those skilled in the art better understand the technical scheme of the present invention, the present invention will be further described below in conjunction with embodiment:

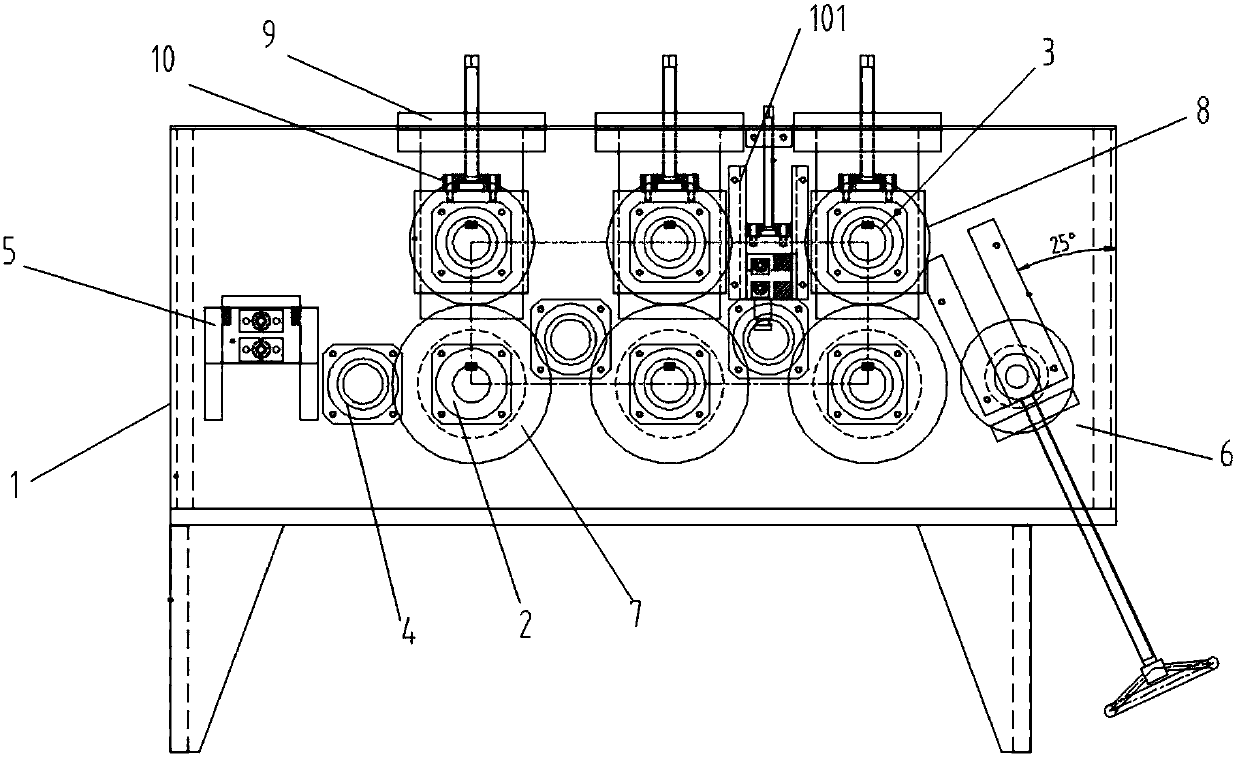

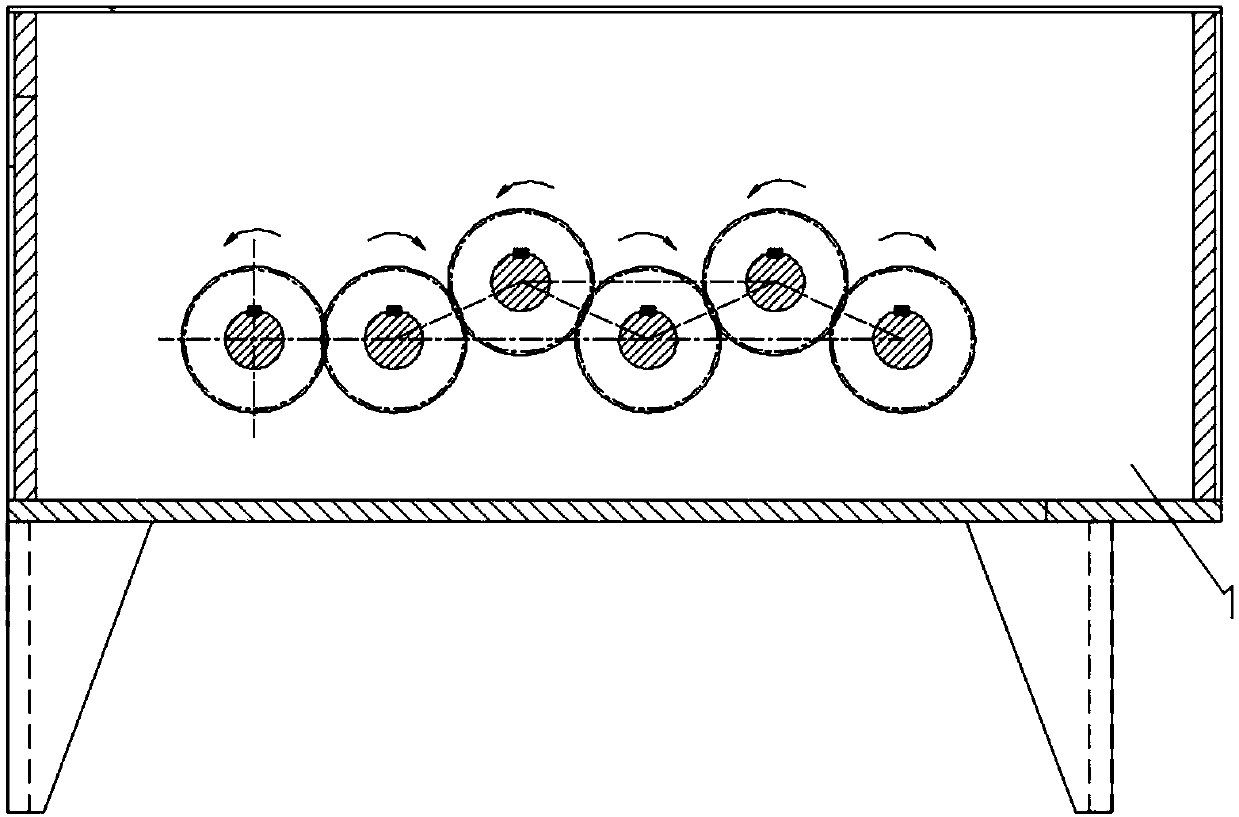

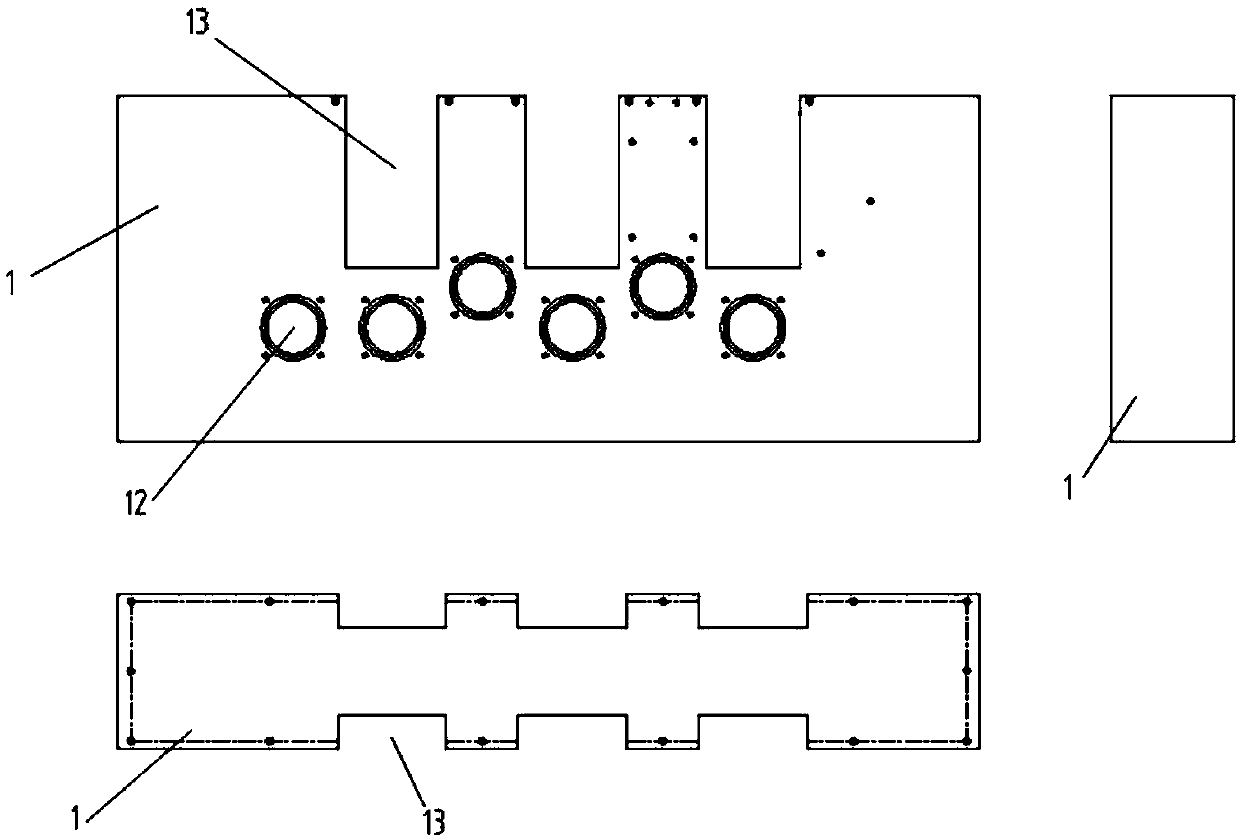

[0026] A kind of coiling machine tool, comprises box body 1, and described box body 1 is provided with multiple sets of lower mold shafts 2, and the top of described lower mold shafts 2 is correspondingly provided with the same number of upper mold shafts 3, and multiple groups One side of the lower die shaft 2 is provided with an output shaft 4, one side of the output shaft 4 is provided with a lower die positioning assembly 5, and the other side of the plurality of sets of the lower die shafts 2 is provided with a diameter adjustment assembly 6. One end of the lower mold shaft 2 and the upper mold shaft 3 in multiple groups extends out of the box body 1, and the lower mold 7 is provided at one end of the lower mold shaft 2 in multiple groups, and the upper mold shaft in multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com