A method for conducting air in the connecting cavity and pressure grouting for sleeve grouting connection

A grouting connection and grouting technology, which is applied to ceramic molding machines, manufacturing tools, etc., can solve problems such as insufficient air removal, and achieve the effects of improving construction efficiency and simplifying work processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

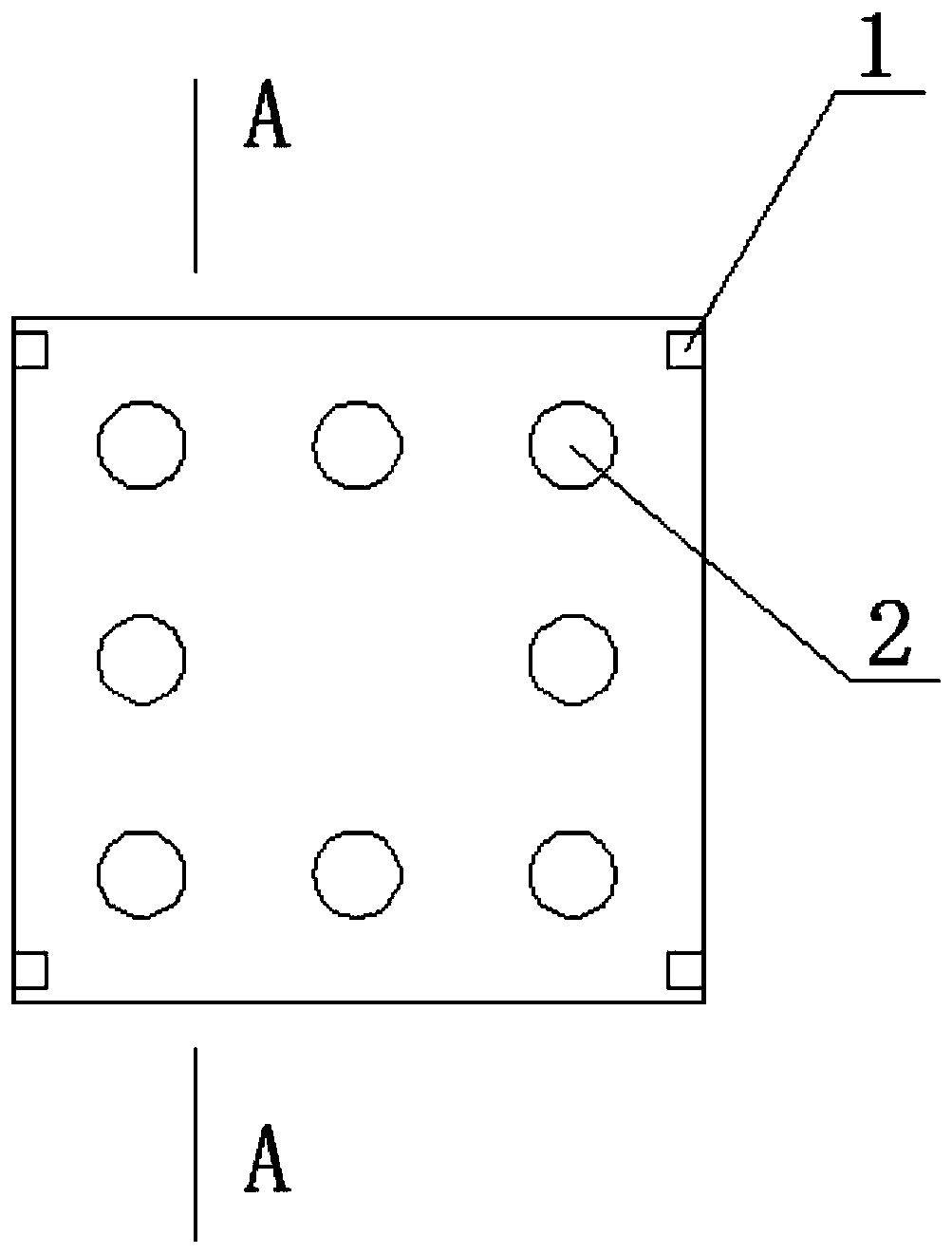

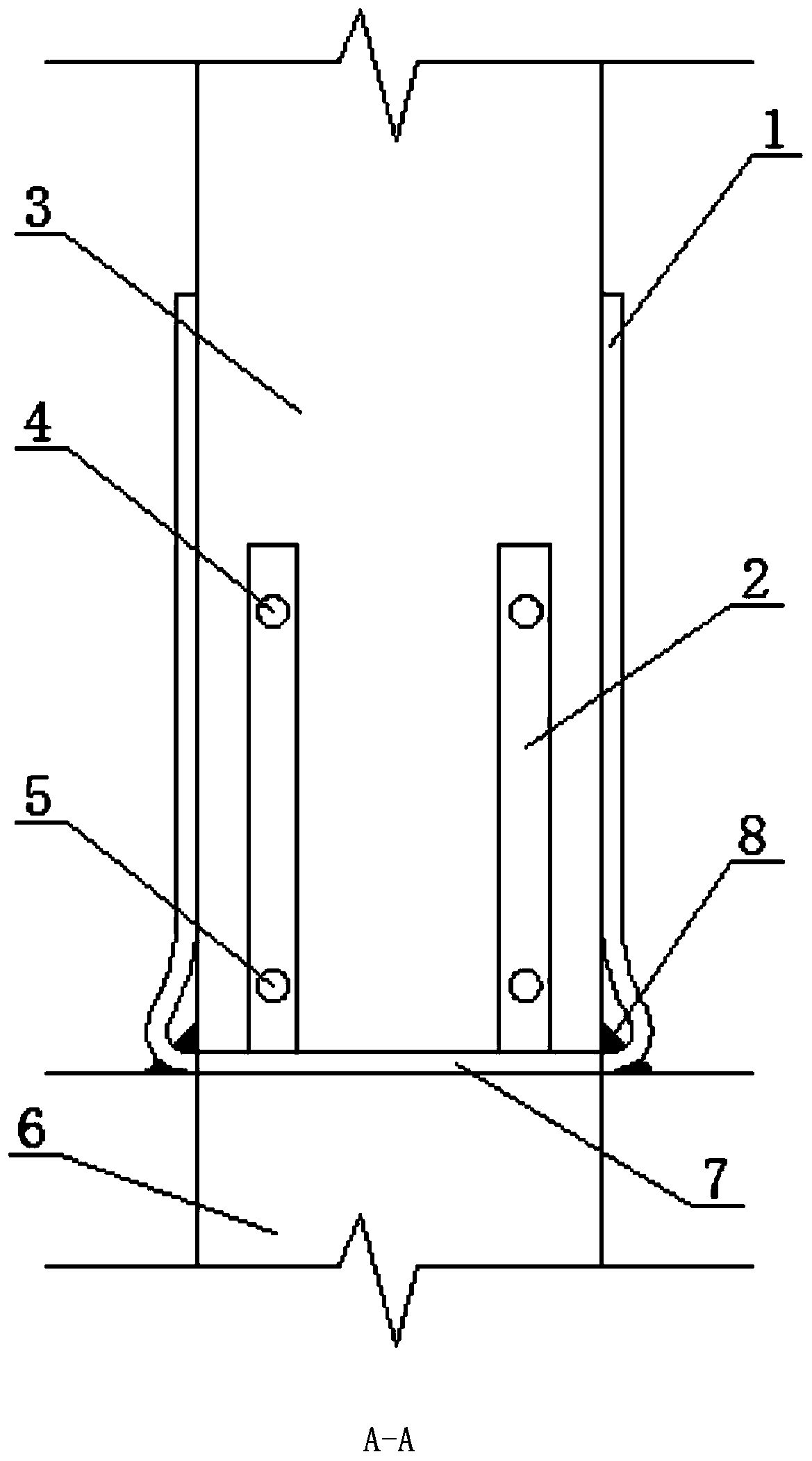

[0028] The prefabricated concrete components or the upper and lower section prefabricated components mentioned in this application can be prefabricated concrete columns or prefabricated concrete walls. In this embodiment, taking the connection process of the upper and lower prefabricated components of the precast concrete column as an example, the air guiding and pressure grouting method of the connecting cavity of the present invention is specifically described. For specific content, refer to figure 1 , figure 2 shown.

[0029] The operation process of the present embodiment is as follows.

[0030] 1. Preparation of grouting material:

[0031] The mixing water of the grouting material shall be potable water, and other water shall comply with the provisions of the "Standard for Concrete Mixing Water" (JGJ63-2006).

[0032] The ambient temperature should meet the requirements of the instruction manual of the grouting material product. When the temperature is too high, the ...

Embodiment 2

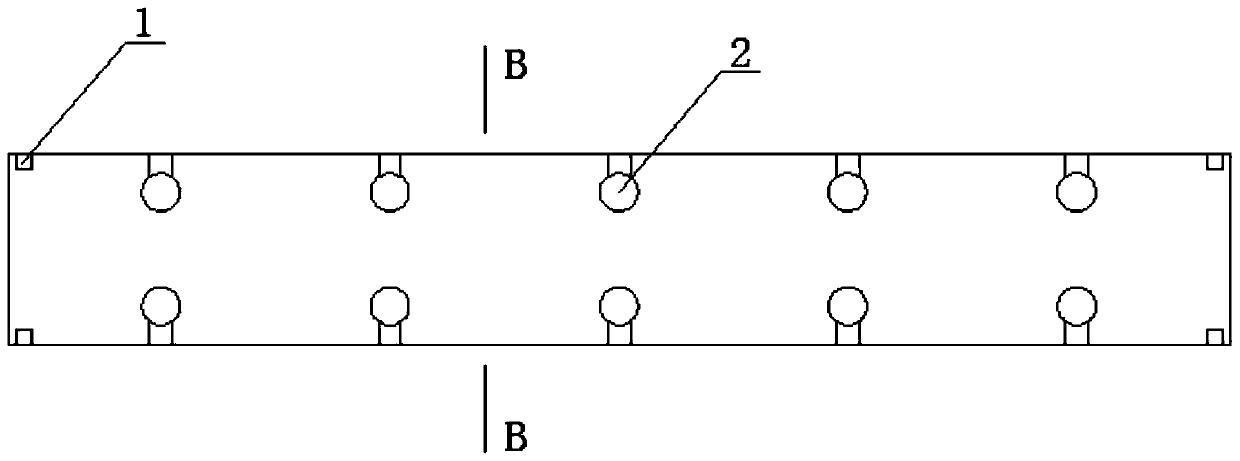

[0047] The difference between this embodiment and the first embodiment is that the concrete components for construction are replaced by prefabricated concrete columns and prefabricated concrete walls. For details, see image 3 , Figure 4 shown. The prefabricated concrete wall is divided into an upper prefabricated wall 8 and a lower prefabricated wall 9 .

[0048] The difference when it is applied to a prefabricated concrete wall is that when the length of the prefabricated wall is longer, it is necessary to divide the joint communication cavity 7 into bins and use segmented grouting. At this time, the position of the air guiding hose 1 is correspondingly arranged at the four corners of the connecting cavity 7 in different sections of the seam, and the process of the connecting cavity air guiding and pressure grouting in the first embodiment is repeated respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com