Ultra-low flow resistance microchannel liquid-cooled heat exchanger based on elastic turbulence and its manufacturing method

A liquid-cooled heat exchanger and elastic turbulent flow technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc. The effect of reducing flow pressure drop and facilitating design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

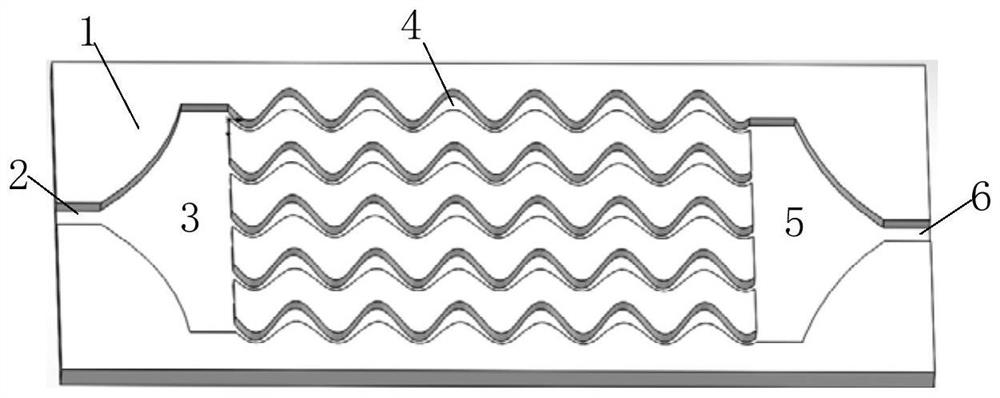

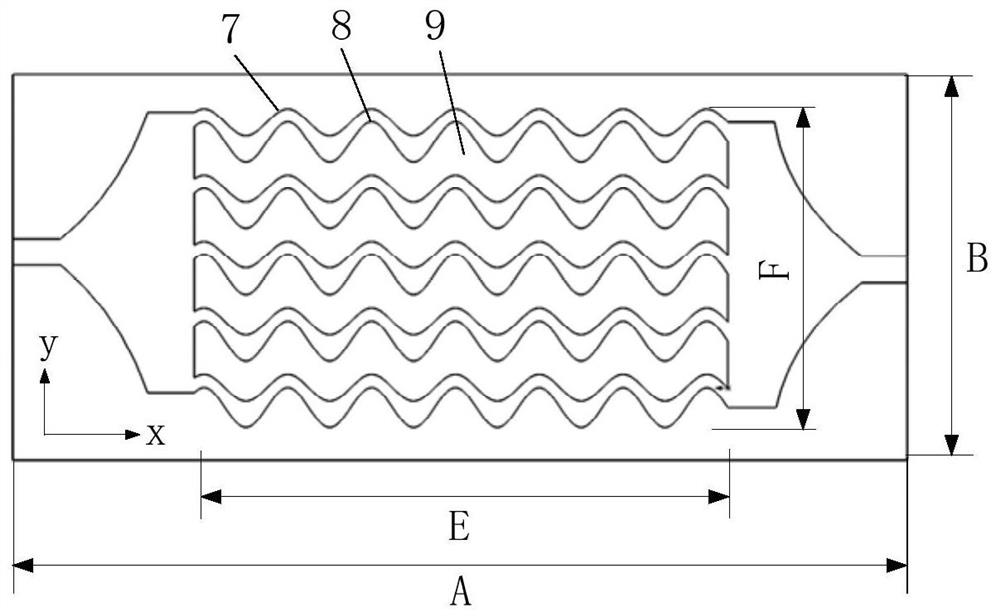

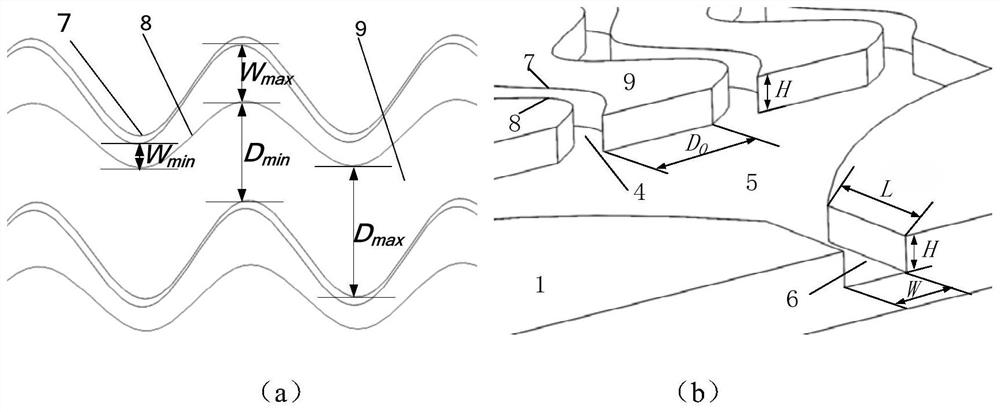

[0036] see Figure 1 to Figure 4 , the object of the present invention is to utilize "elastic turbulent flow can be in ultra-low Re number (can be as low as Re=10 -2 The principle of being triggered to form an unstable flow under the order of magnitude), combined with the specially designed periodic bending-variable cross-section micro-channel, provides a new type of micro-channel heat exchanger with ultra-low flow resistance and low pump work, Including working fluid (working fluid is viscoelastic fluid, specifically polymer or surfactant solution) and microchannel radiator. See figure 1 , the microchannel heat sink is formed by bonding and sealing the heat dissipation bottom plate 1 and the cover plate 10 . The heat dissipation bottom plate 1 is provided with a working fluid inlet 2, a liquid separation area 3, a number of periodically curved-variable cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com