Spiral reducing-continuous twisting extrusion die for magnesium alloy high-performance plate

An extrusion die, high-performance technology, applied in the direction of metal extrusion dies, etc., can solve the problem of plate blank thickness thinning, etc., achieve the effect of large shear stress, reduce the number of turns, and increase the torsion radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

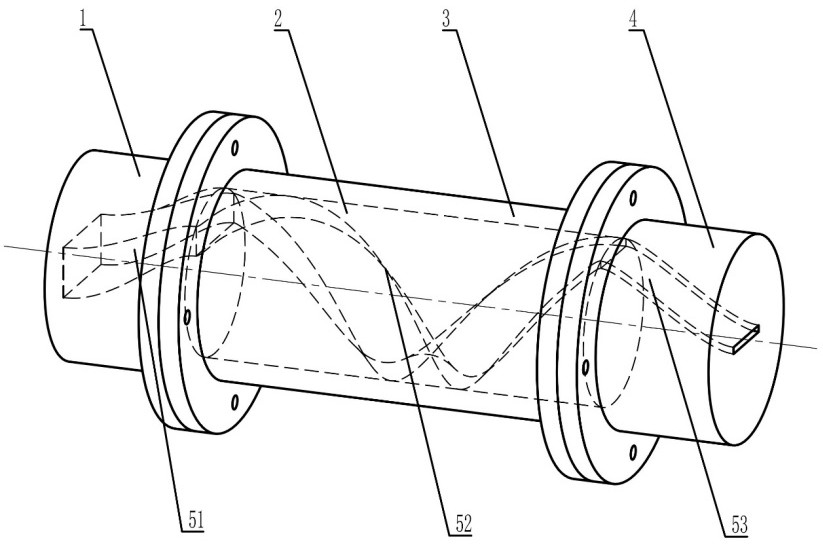

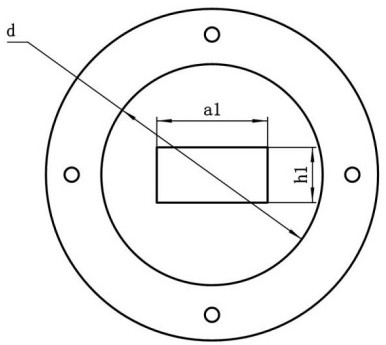

Embodiment 1

[0019] In this embodiment, an AZ31 magnesium alloy cuboid extruded billet is selected, and the original size specifications are: width a is 180 mm, thickness h is 80 mm, and length is 2000-3000 mm. The embodiment is to first heat the billet to 250 ° C, keep it for an appropriate time and make the temperature uniform, and heat the mold at the same time to make its temperature rise to the same temperature as the billet to be processed, and then twist the extrusion channel 5 in the screw of the mold and the feeding extrusion. Lubricant is applied to the cavity of the die 1 and the cavity of the exit extrusion die 4. Put the blank to be processed into the cavity 1 of the feeding extrusion die, open the extrusion device, and apply pressure at the rear end of the blank to feed 10-15 mm / s, so that the blank passes through the cavity 1 of the feeding extrusion die and enters the middle. The helical twist extrusion channel 5 performs twist extrusion, and finally the formed plate is obt...

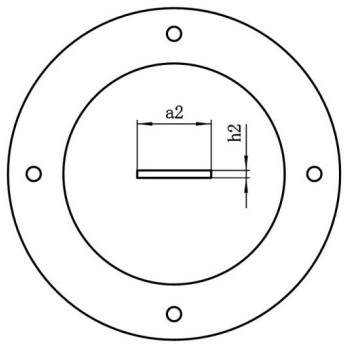

Embodiment 2

[0022] In this embodiment, an AZ31 magnesium alloy rolled sheet is selected, and the size of the sheet is: width a180mm and thickness h36mm. Length 2000mm. First, 3 to 5 sheets are stacked together, heated to 250°C, and kept for an appropriate time to homogenize the temperature of the material. At the same time, the mold is also heated to 250°C, and then lubricant is applied to the cavity of the mold. Start the pressure device, and under the action of pressure, make the sheet pass through the feed extrusion die 1, the spiral twist extrusion channel 5 and the outlet extrusion die 4 in sequence at a speed of 12-15mm / s. Composite together, and finally obtain a composite board with a width of 135mm × 15mm. And after shear deformation along the cross-section direction, the microstructure and properties of the composite sheet are greatly improved.

[0023] The mechanical properties of the sheet after extrusion in this example are as follows: the tensile strength is: 365Mpa~378Mpa,...

Embodiment 3

[0025] like Figure 5 As shown, it is the modified rod-shaped material torsion forming die of the present invention. The cross section of the beginning section of the cavity of the feed extrusion die 1 and the end section of the exit extrusion die 4 is changed from a rectangle to a circle, so that the improved die cavity can complete the extrusion of the bar. In this embodiment, as-cast ZK60 bar blanks with a diameter of φ180mm × length of 1200mm are selected. First, the bar blanks are heated to 300°C for an appropriate time to make the temperature uniform. The billet temperature is the same. Then apply lubricant in the die cavity, put the blank to be processed into the cavity 1 of the feed extrusion die, and apply pressure at the rear end of the bar blank for 8-12mm / s constant velocity extrusion, so that the blank passes through the feed extrusion. The cavity of the die 1 enters the middle spiral extrusion channel 5 for torsional extrusion, and finally passes through the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com