Cement mobile home and manufacturing method thereof

A manufacturing method and mobile room technology, applied in the field of construction, can solve the problems that foam plastics are easily scattered with the wind, cannot be reused, and the operation is not very convenient, so as to achieve convenient and fast installation and disassembly operations, shorten the production cycle, and save manpower Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

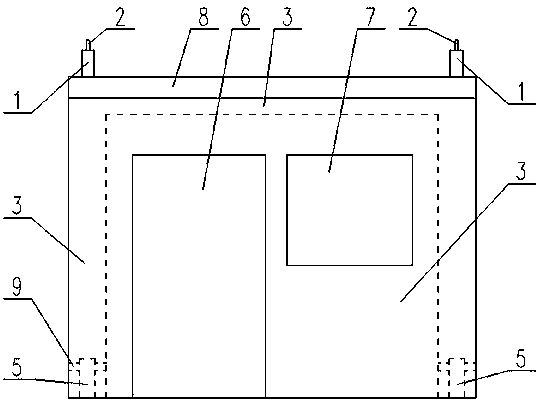

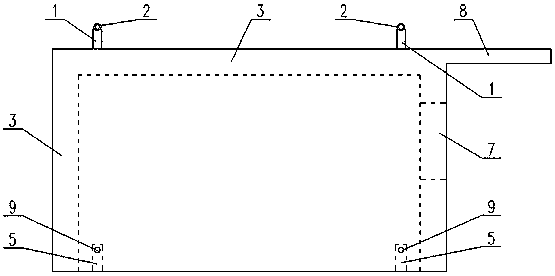

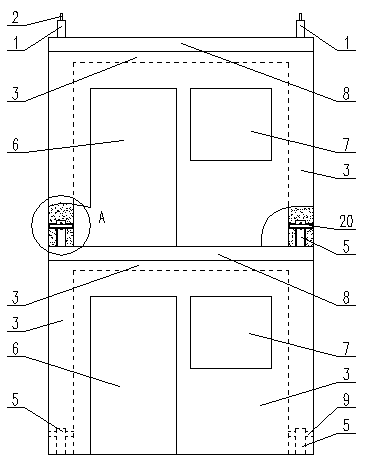

[0023] Depend on figure 1 and figure 2 As shown, a cement movable house mainly includes a house body 3 and a positioning rod 1, the house body 3 is an integral reinforced concrete structure, and the positioning rod 1 is fixedly installed on the top of the house body 3, and is connected with the The steel frame in the room body 3 is fixedly connected, and a positioning hole 5 is provided at the bottom of the room body 3. The positioning hole 5 corresponds to the positioning rod 1 on the top of the room body 3. The upper end of the positioning rod 1 is provided with a Hanging ring 2, at the positioning hole 5 at the bottom of the room body 3, there is a locking through hole 9 intersecting in the horizontal direction, the locking through hole 9 corresponds to the hanging ring 2, and the room body 3 is also provided with a door slot 6 and a window slot 7. A support plate 8 extending to the side where the door slot 6 is opened is also provided on the top of the room body 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com