Loading and assembling device for filter cotton of gas filter pipe

An assembly device and filter cotton technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, household components, etc., can solve the problems of unsuitable gas filter tubes, filter cotton feeding assembly devices without gas filter tubes, etc., and achieve compact structure, Wide range of applications, beneficial to the effect of retrieving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

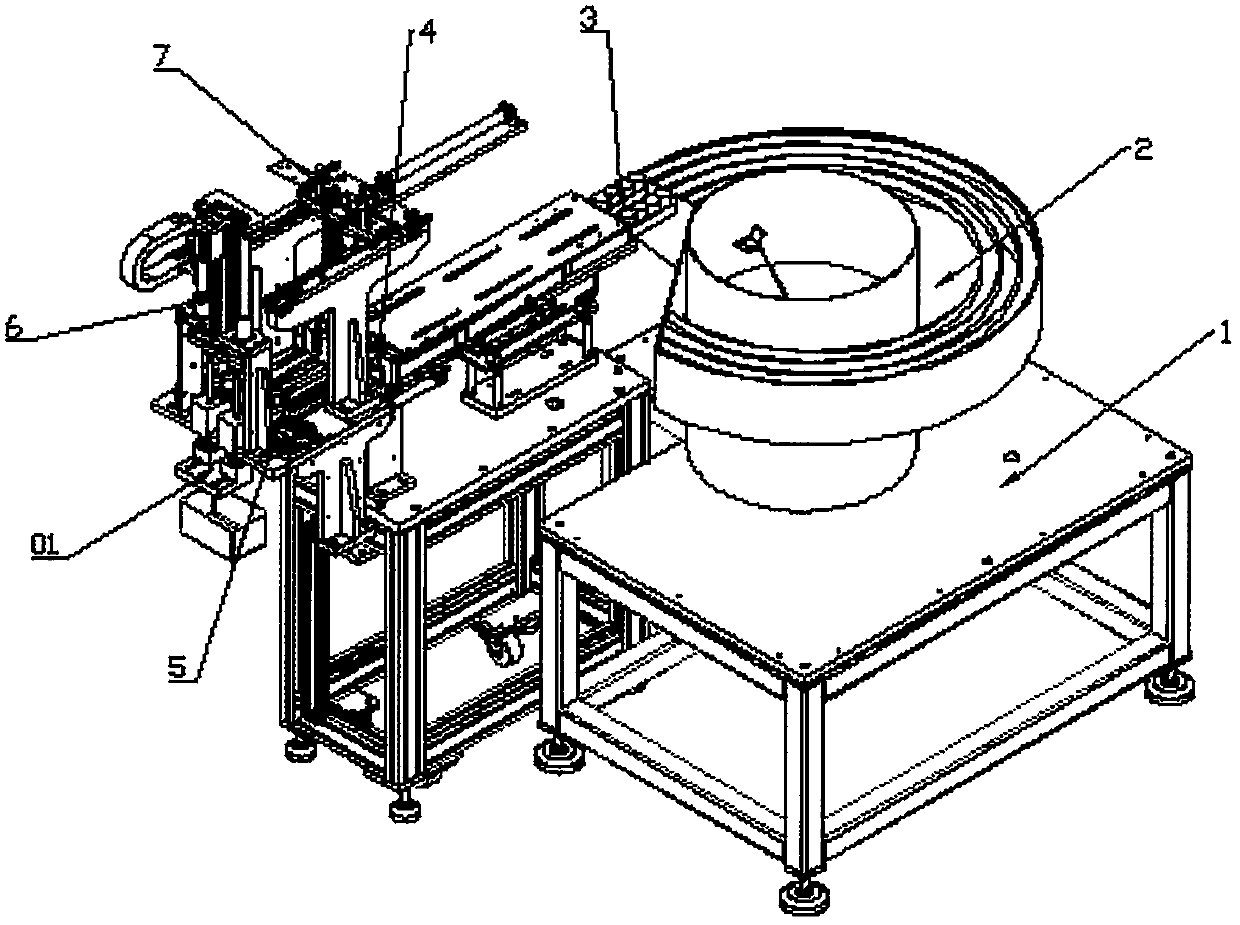

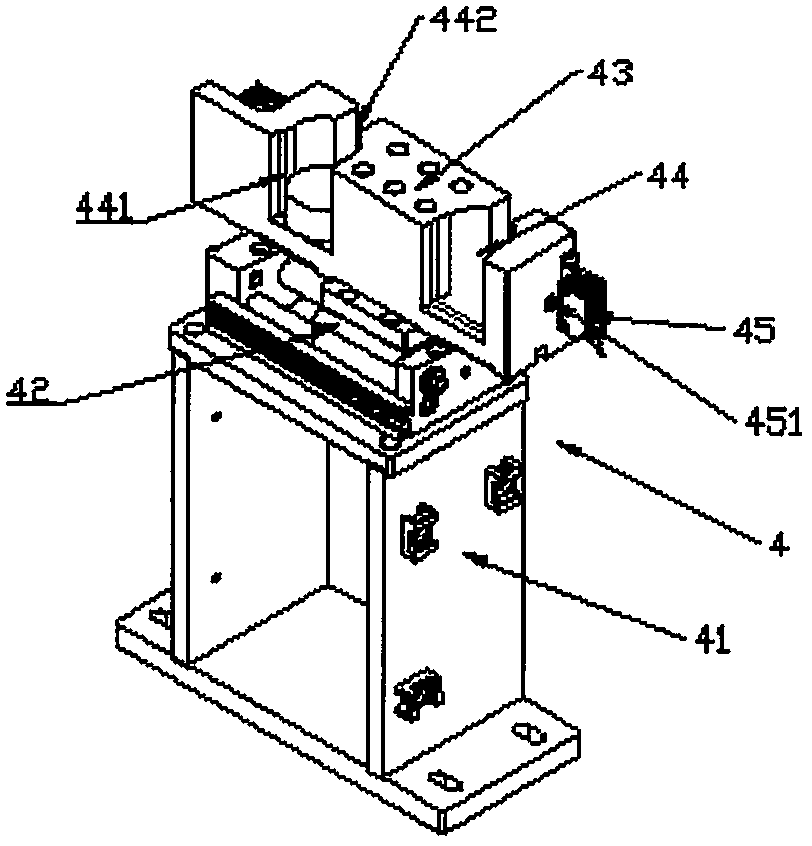

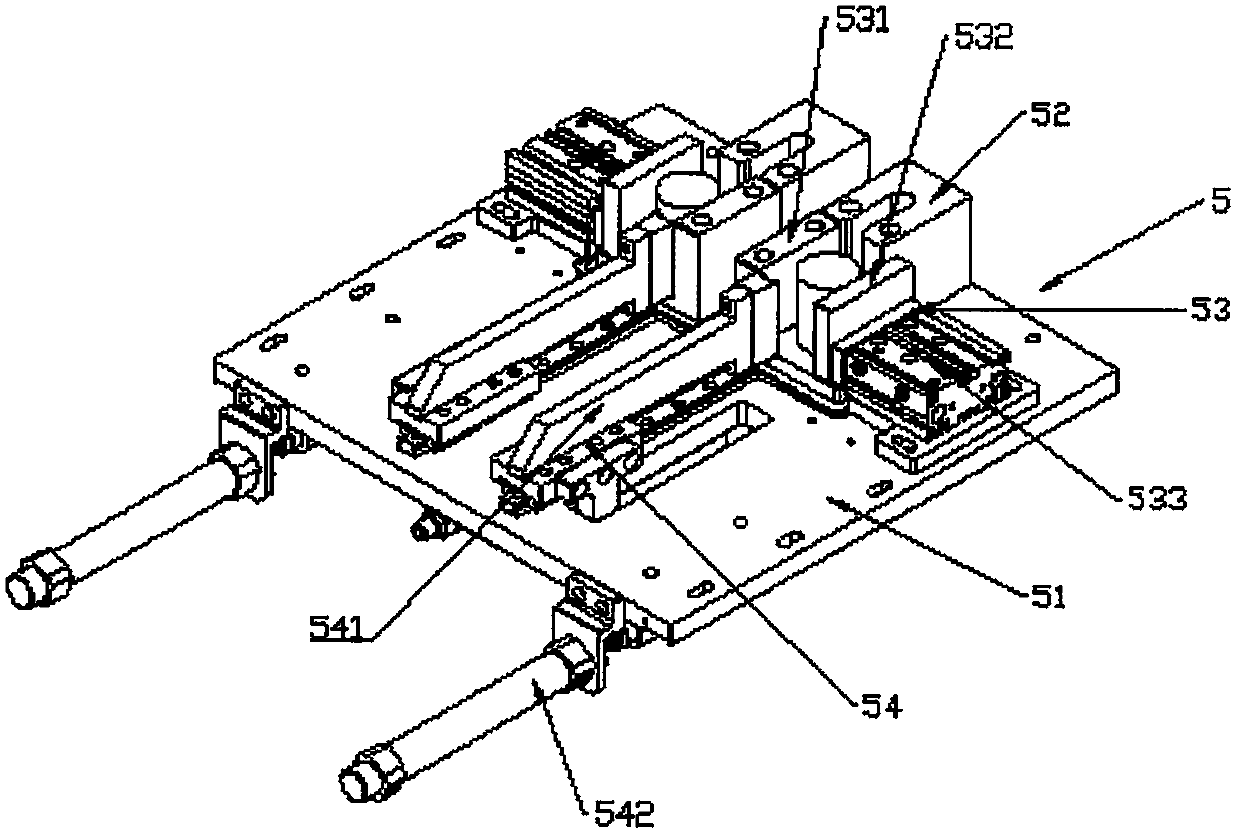

[0028] Such as Figure 1-7 As shown, a filter cotton feeding assembly device for a gas filter tube includes a frame 1, on which a filter cotton vibrating plate 2, a filter cotton flat feeding mechanism 3, and a filter cotton material receiving mechanism are sequentially arranged on the frame from back to front 4. Filter cotton compression mechanism 5, filter cotton press-down assembly mechanism 6, above the filter cotton compression mechanism 5, there is also a filter cotton transfer mechanism for transferring the filter cotton in the filter cotton material receiving mechanism 4 to the filter cotton compression mechanism 5 Institution7.

[0029] The gas filter tube referred to in this embodiment includes an integrally formed plastic tube and filter cotton assembled in the plastic tube. Wherein the plastic tube is in the shape of a Chinese character, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap