A wing rib conformal tooling for a large aircraft

A technology of rib and tooling, applied in the field of digital assembly of large aircraft, can solve the problems affecting the accuracy of hole making and connection accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

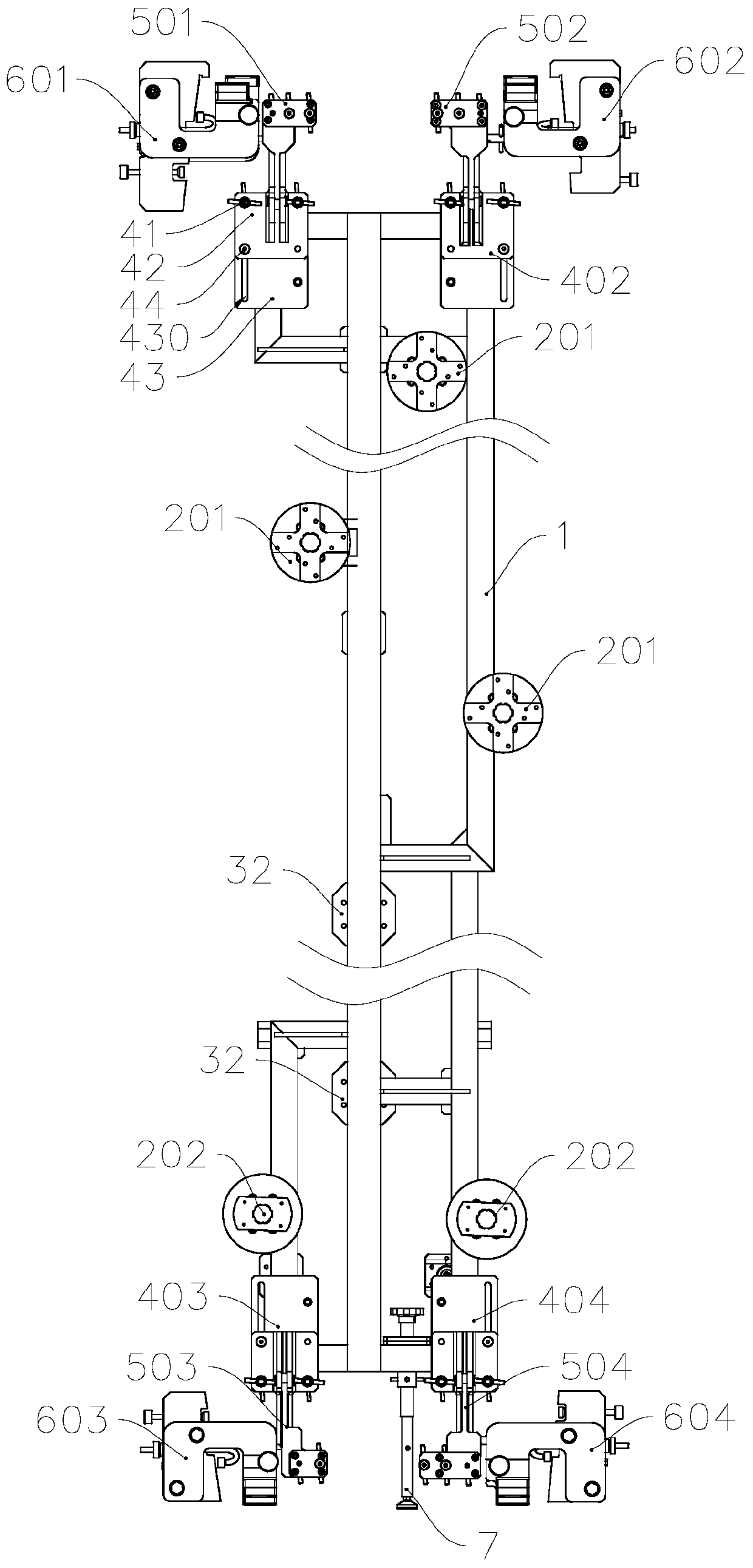

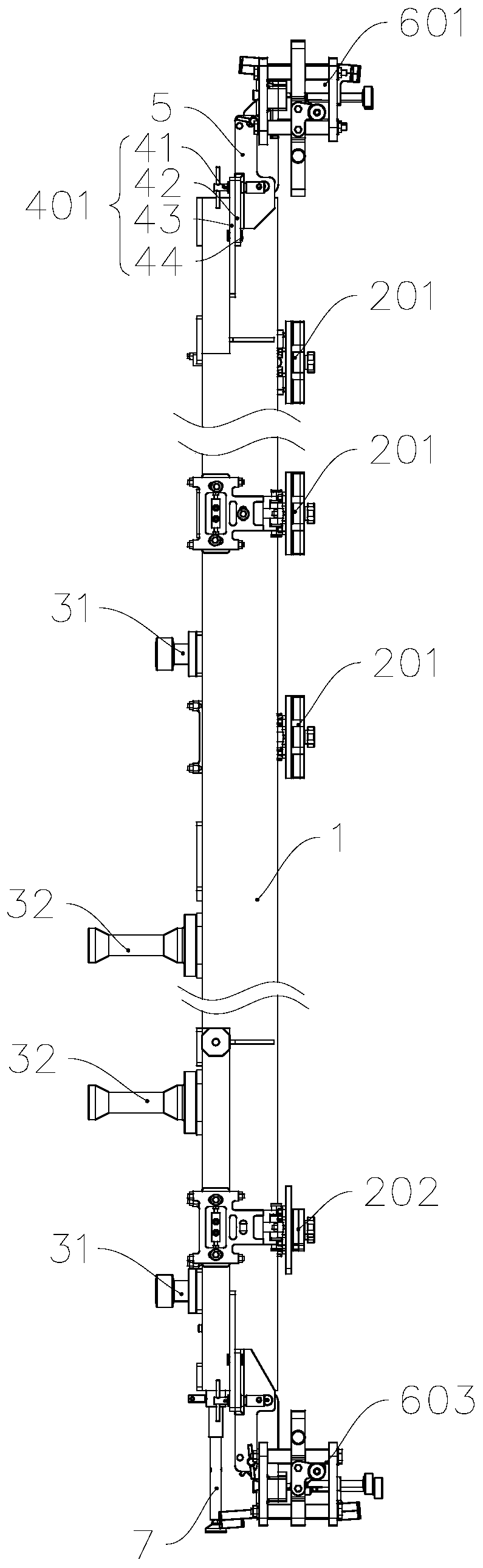

[0025] see figure 1 and figure 2 , the shape-preserving tooling includes a shape-preserving frame, a front upper positioning assembly 602 , a rear upper positioning assembly 601 , a front lower positioning assembly 604 and a rear lower positioning assembly 603 . The shape-preserving frame includes a bracing frame 1, rib face retaining parts 201, 202, front beam airfoil connectors 502, 504, rear beam airfoil connectors 501, 503, beam connecting plate bearings 401, 402, 403, 404, and solid The adjustment bolt 7 that is located at the lower end of the support frame. On the side of the support frame 1 away from the rib surface stoppers 201, 202, a number of clamping rivets 31, 32 arranged at intervals along the course for carrying the rib shape-conserving tooling are installed, so as to realize fast clamping on the trolley. Fast clamping and release by the holding mechanism, so as to improve the handling efficiency and quality.

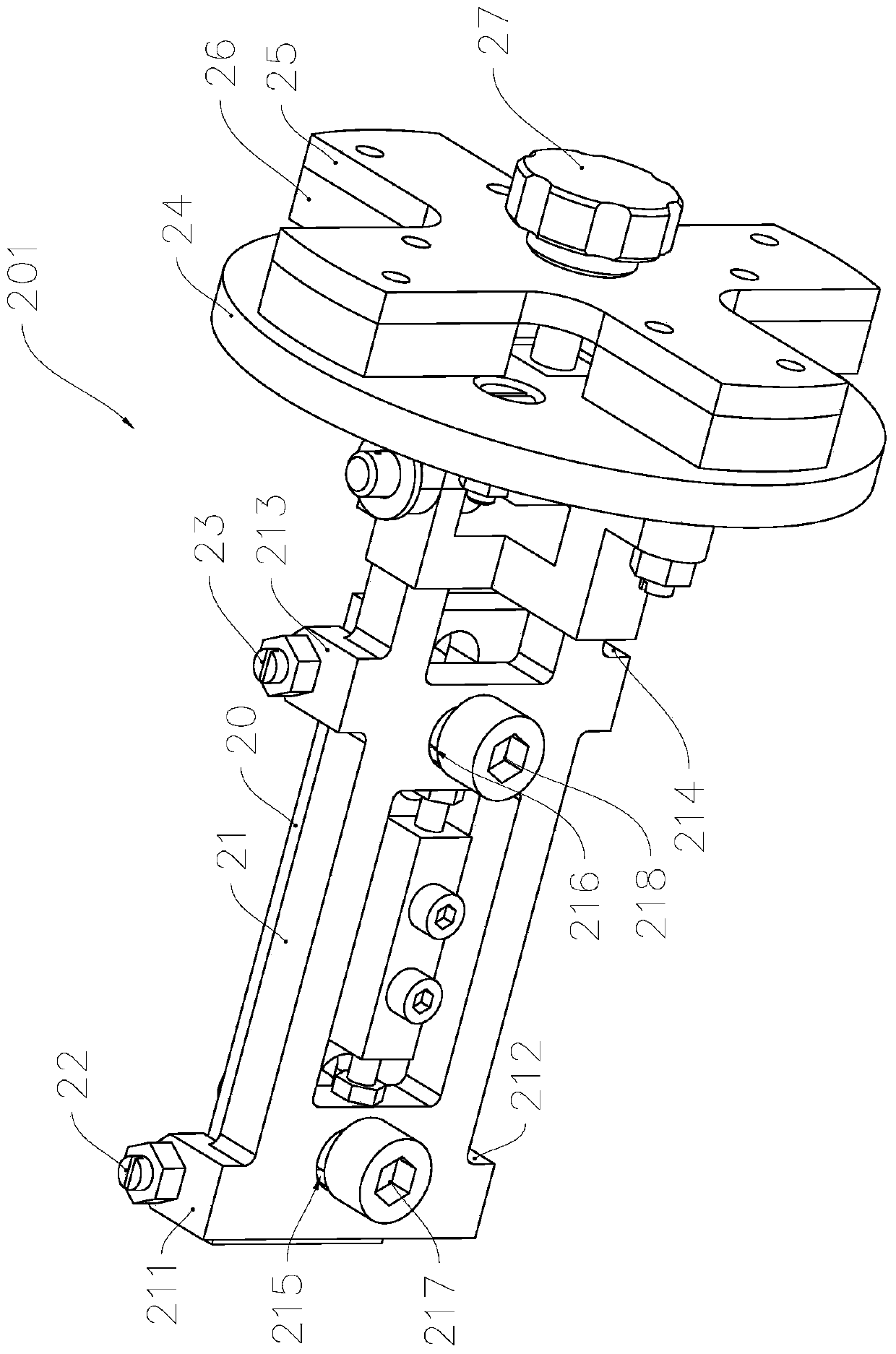

[0026] see Figure 1 to Figure 3 The rib surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com