Wire harness terminal protecting cup

A wire harness terminal and protection cup technology, applied in the field of wire harness terminal protection cups, can solve the problems of wire harness terminal damage and wear, protection cup friction, cumbersome clamping and fixing process of wire harnesses, etc., and achieve the effect of wide application and improved use flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

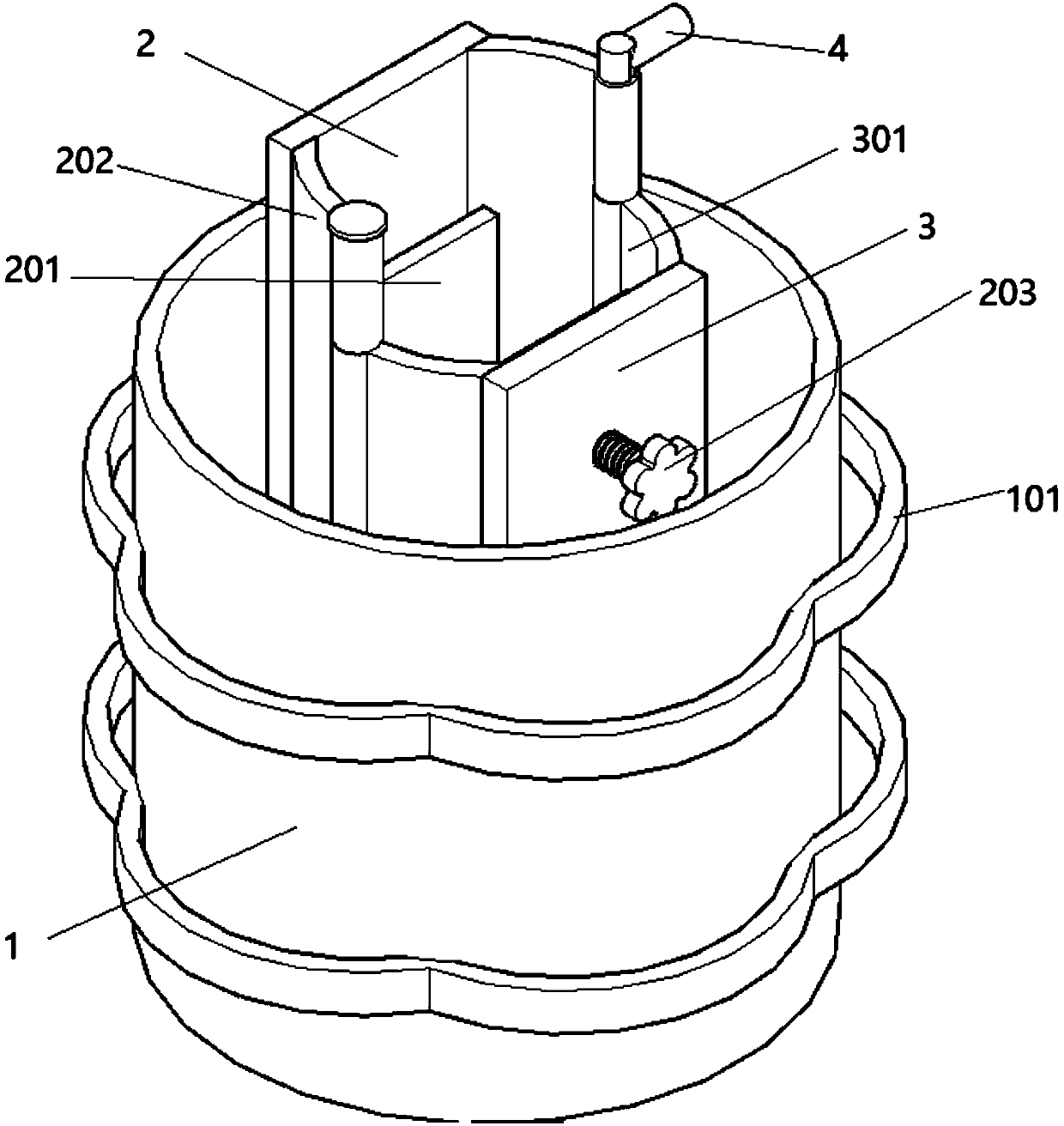

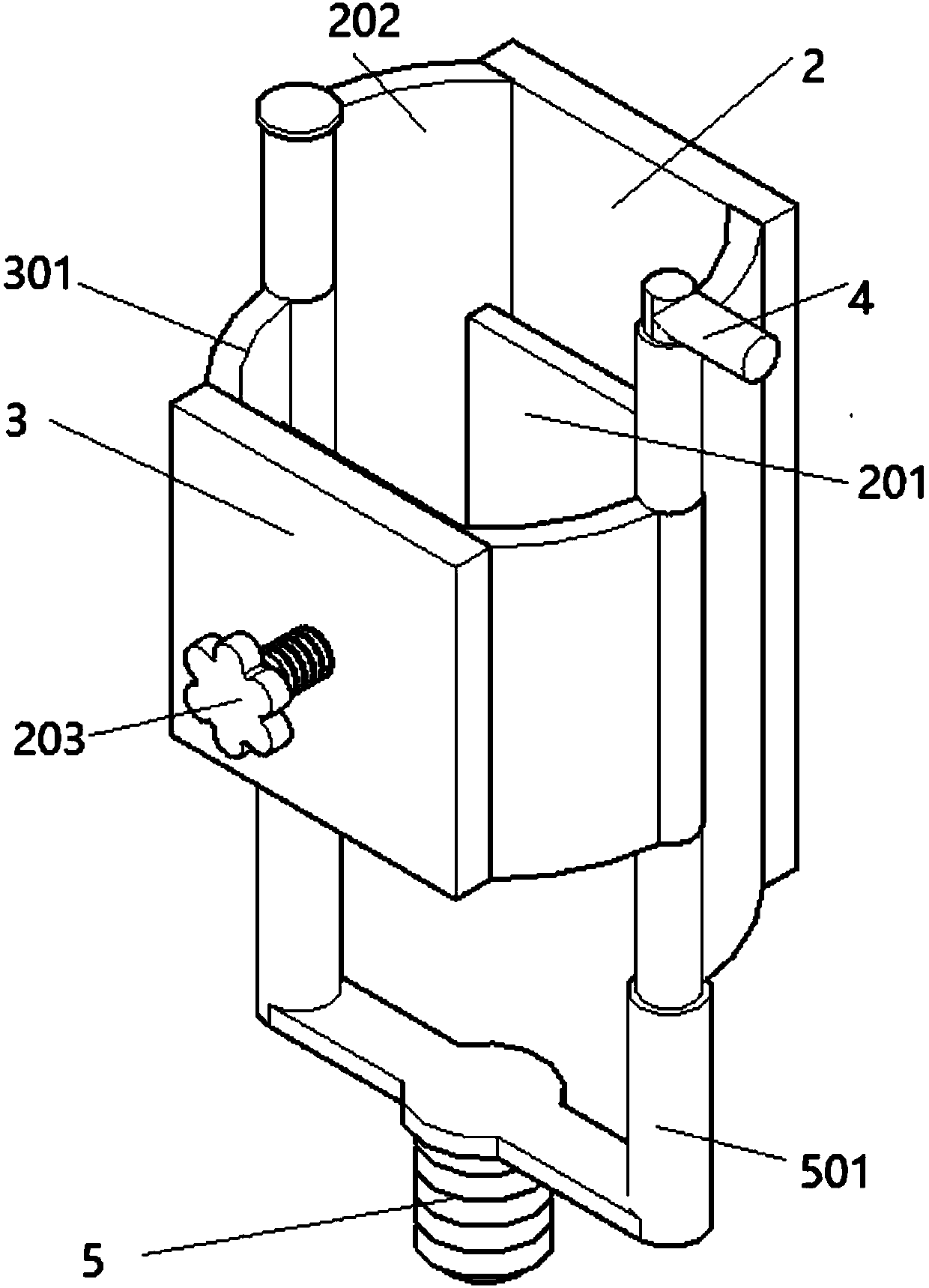

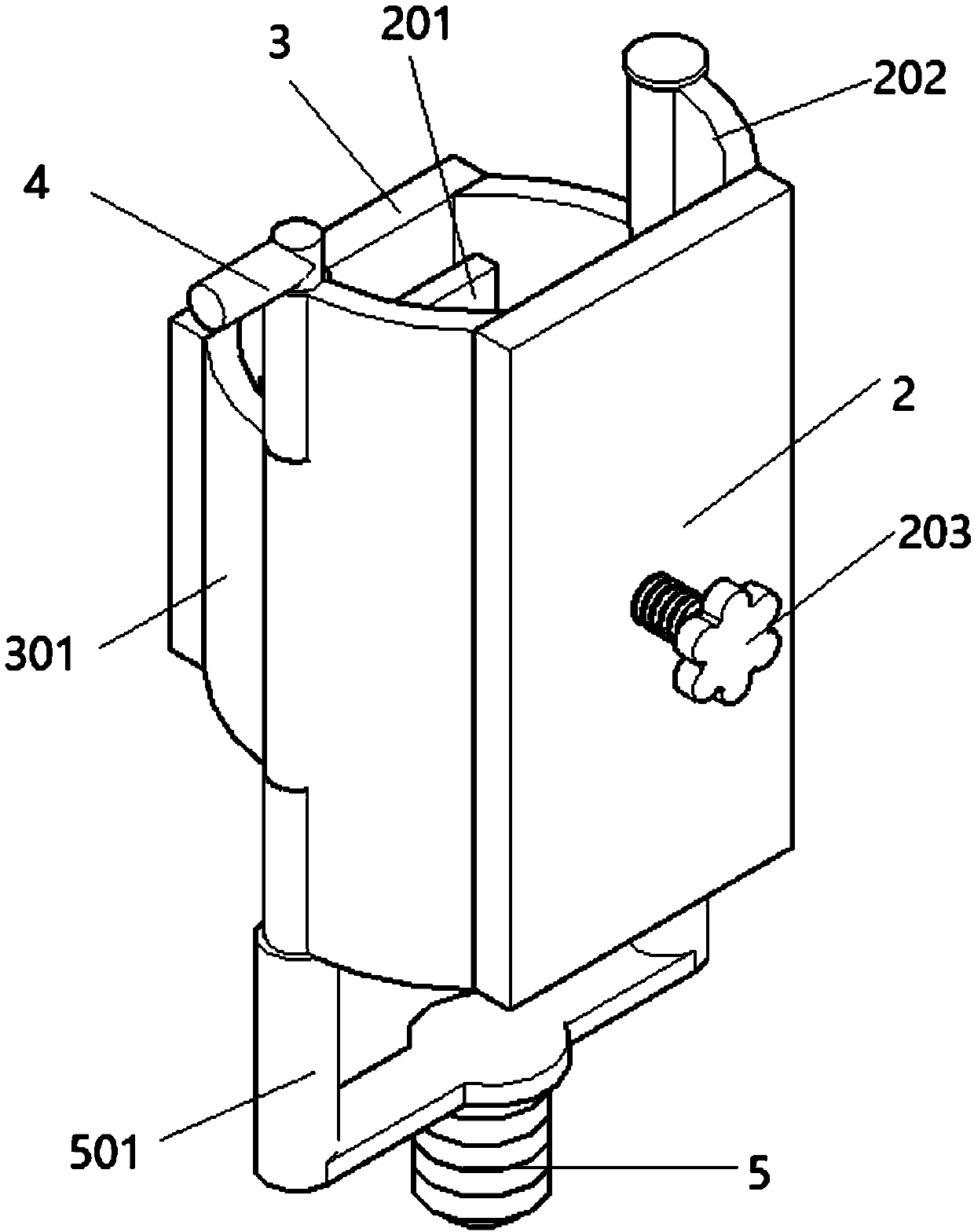

[0025] as attached figure 1 To attach Figure 5 Shown:

[0026] The present invention provides a wire harness terminal protection cup, which includes a protection cup body 1, an arc-shaped buffer plate 101, a threaded fixing sleeve 102, a first pressing plate 2, a tightening square plate 201, a first supporting arc plate 202, and a tightening Bolt 203, second pressing plate 3, second supporting circular arc plate 301, positioning inserting rod 4, supporting threaded rod 5 and supporting rod 501, five arcs are fixed in an annular array on the outer wall of the protective cup body 1. shaped buffer plate 101; the left and right sides of the second pressing plate 3 are connected and fixed with two first supporting arc plates 202, and the second pressing plate 3 and the two first supporting arc plates 202 are combined to form Rear wiring harness pressing ring; the second pressing plate 3 is combined with two second supporting arc plates 301 to form a front wiring harness pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com