Lifting structure for transfer of large concrete blocks

A concrete and large-scale technology, which is applied in the field of hoisting structures for the transfer of large concrete blocks, can solve problems such as safety accidents, achieve the effect of ensuring personal safety and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

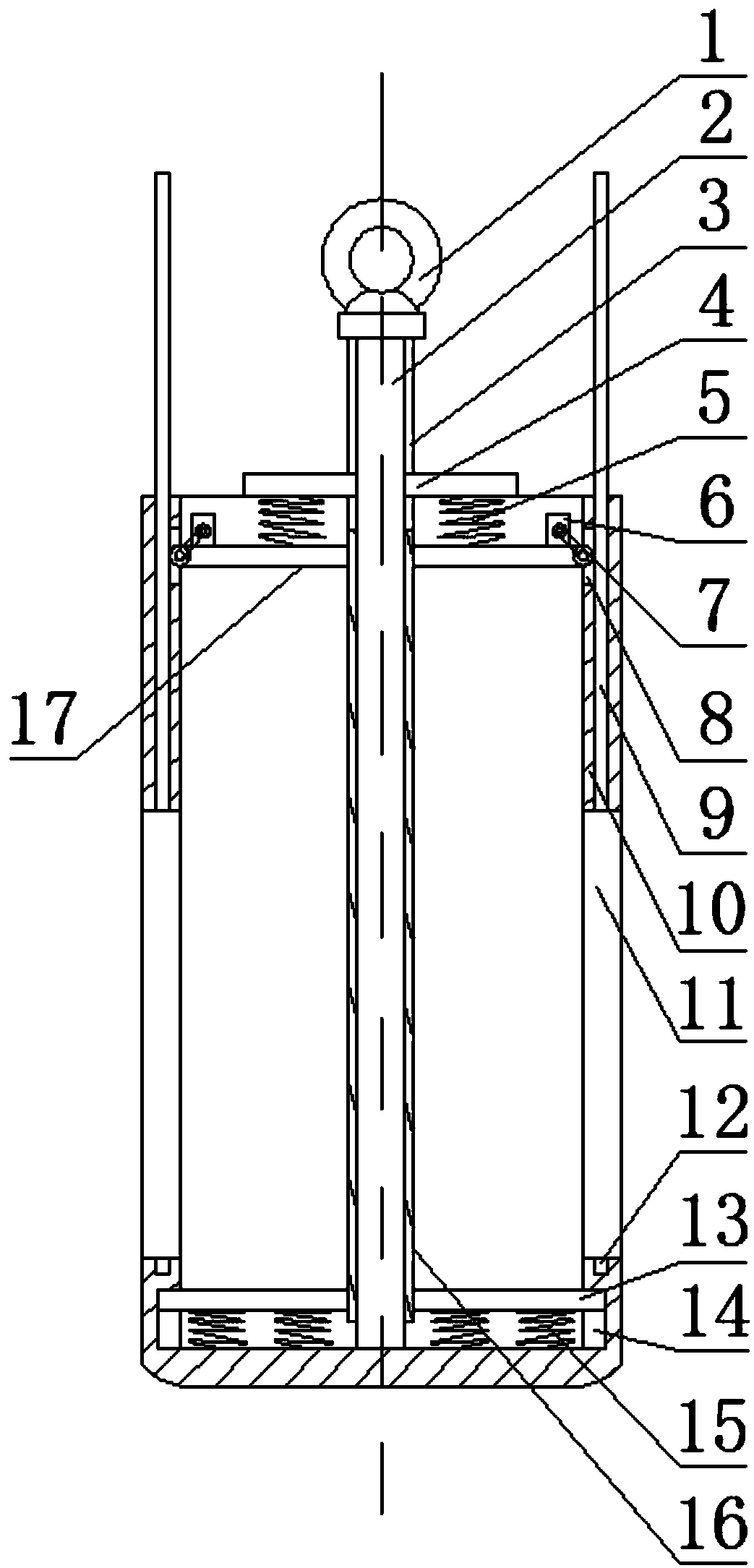

[0021] Such as figure 1 As shown, this embodiment includes a rectangular frame body 10 with an open upper end and a connecting rod 2, the upper end of the connecting rod 2 is fixed with a hanging ear 1, the lower end of the connecting rod 2 is placed in the frame body 10 and connected to the bottom of the frame body 10, and The two opposite side walls of the frame body 10 are respectively provided with feed inlets 11, and a sleeve 16 is sleeved on the outer peripheral wall of the connecting rod 2, and a sleeve 16 is provided on the upper end side wall along the axis of the sleeve 16. Two mutually symmetrical longitudinal grooves 3, the limit plate 4 is connected with the outer wall of the connecting rod 2 after passing through the longitudinal groove 3, and support plates 17 are respectively fixed on the two side walls of the sleeve 16, and the support plates 17 is connected with the limiting plate 4 through the first spring 5, the bottom plate 13 is respectively fixed on the ...

Embodiment 2

[0024] Such as figure 1 As shown, in this embodiment, a channel communicating with the feed inlet 11 is provided on two opposite side walls of the frame body 10 , and the side baffle 9 is slidably disposed in the channel. After putting the small section of the inner support beam into the frame body 10, and when other construction wastes continue to be put in, the upper end of the inner support beam is filled with relatively small residual blocks to make full use of the inside of the frame body 10. The space is finally moved down by the side baffle plate 9 in the channel to close the feed port 11, preventing the inner supporting beam segments or fragments from falling from the inside of the frame body 10.

[0025] A toothed belt is provided on the inner side wall of the side baffle 9, an opening 8 communicating with the channel is provided on the inner side wall of the upper section of the frame body 10, and a motor 6 is provided on the two support plates 17, and The outer end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com