A device for shuttle-like weaving of bundled filaments

A filament and bundle technology, which is applied in the field of bundle filament shuttle weaving devices, can solve the problems of beautiful appearance and mechanical properties of bundle filament fabrics, consume a lot of manpower and material resources, and poor appearance performance, etc., to achieve good The effect of promoting value, saving cost and resources, and improving spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A device for shuttle weaving of bundled filaments, comprising a shuttle box, a small cylinder I5, a working special-shaped shuttle 2, a shuttle chuck 1 and a propulsion device;

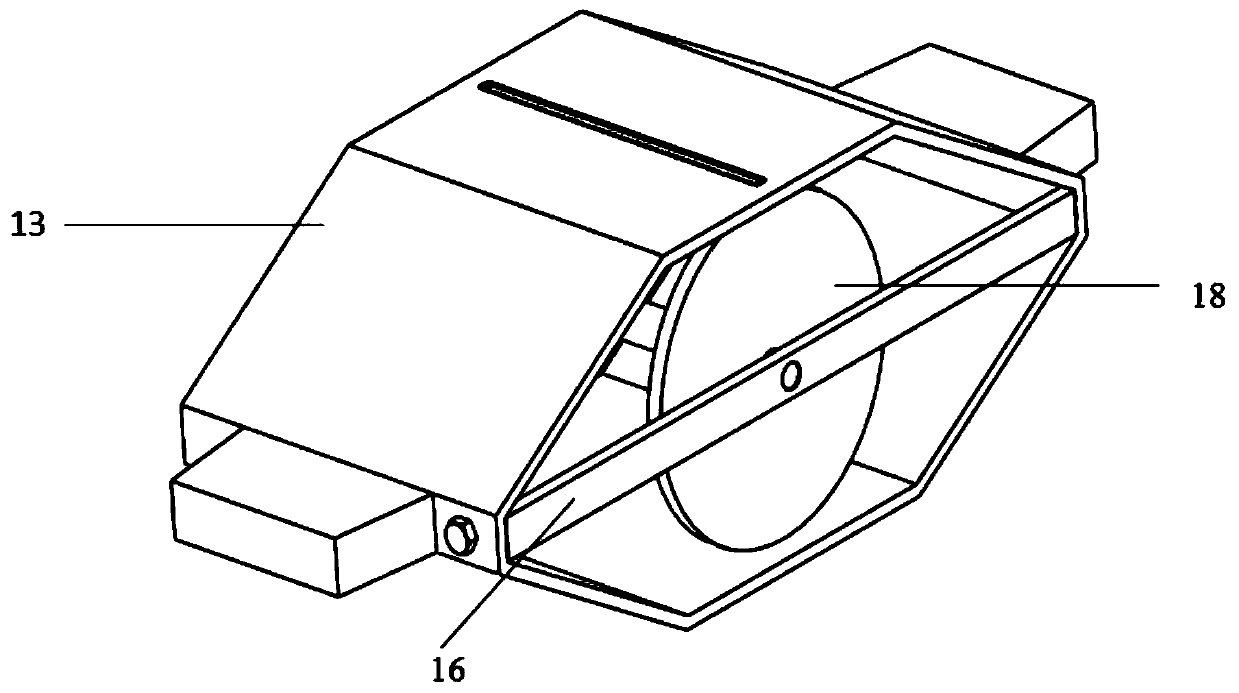

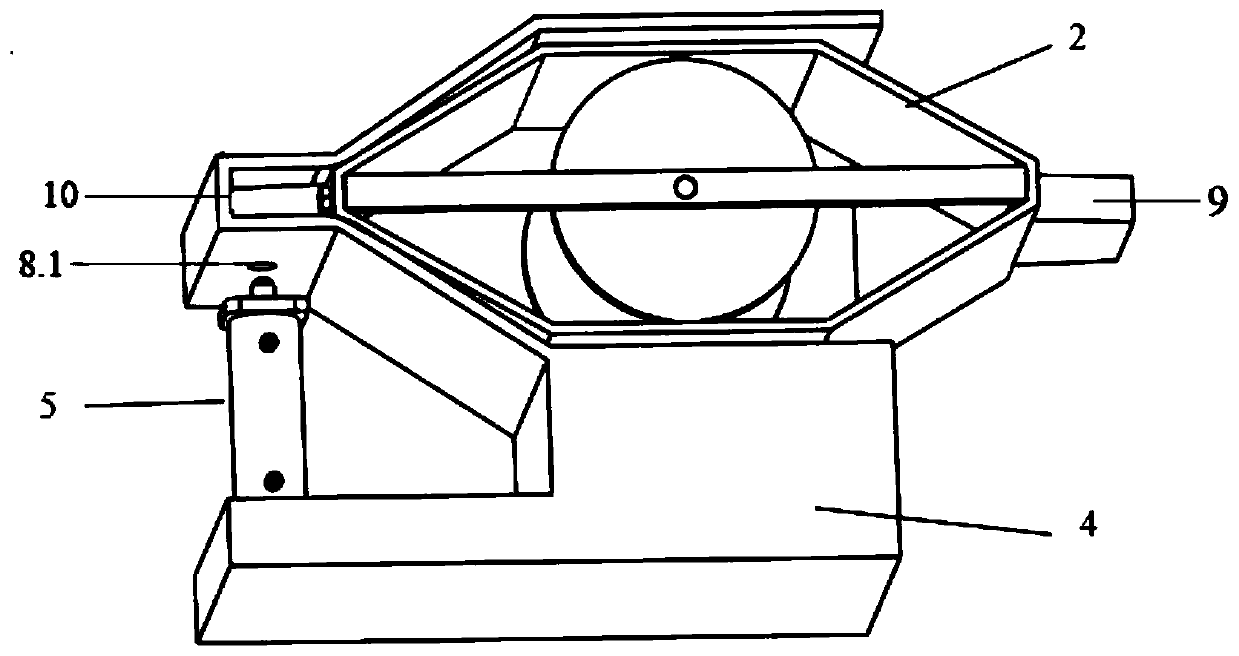

[0040] Such as figure 1 with figure 2 As shown, the working special-shaped shuttle 2 includes a bobbin case 13 and a weft-loading bobbin 14 positioned inside the bobbin case 13. The bobbin case 13 is a hollow octagonal prism whose size gradually decreases from the middle section to the two ends. The two ends extend horizontally from the front plate 7 and the rear plate 9, the front plate 7 is used to be fixedly connected with the shuttle box of the loom, the rear plate 9 is used to cooperate with the propulsion device of the working special-shaped shuttle 2, and the cavity in the middle section of the bobbin case 13 A horizontal bar 17 is fixed, and the length of the horizontal bar 17 is equal to the length of the latitude-carrying cylinder 14, and the horizontal bar 17 is perpendicular to th...

Embodiment 2

[0054] A device for shuttle weaving of bundled filaments, comprising a shuttle box, a small cylinder I5, a working special-shaped shuttle 2, a shuttle chuck 1 and a propulsion device;

[0055] Such as figure 1 with figure 2 As shown, the working special-shaped shuttle 2 includes a bobbin case 13 and a weft-loading bobbin 14 positioned inside the bobbin case 13. The bobbin case 13 is a hollow octagonal prism whose size gradually decreases from the middle section to the two ends. The two ends extend horizontally from the front plate 7 and the rear plate 9, the front plate 7 is used to be fixedly connected with the shuttle box of the loom, the rear plate 9 is used to cooperate with the propulsion device of the working special-shaped shuttle 2, and the cavity in the middle section of the bobbin case 13 A horizontal bar 17 is fixed, and the length of the horizontal bar 17 is equal to the length of the latitude-carrying cylinder 14, and the horizontal bar 17 is perpendicular to th...

Embodiment 3

[0067] A device for shuttle-like weaving of bundled filaments. The basic components and structure are the same as in Example 2, except that the structure and size of the working special-shaped shuttle are changed. The specific differences are: 1) one of the octagonal prisms The bottom surface is closed, and the other bottom surface is not closed. A detachable L-shaped limit plate is provided on the unclosed bottom surface to prevent the weft-carrying bobbin from slipping out of the bobbin case. The horizontal bar is fixed on the closed bottom surface; 2) guide The length of the yarn hole is not less than the length of the bundled filament area on the weft-carrying bobbin, the width of the yarn guide hole is smaller than the height of the bundled filament section, and the difference between the two is 1 / 5 of the bundled filament section height ; 3) The surface of the bobbin case and the guide hole is polished to reduce the friction coefficient with the external bundled filaments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com